Peeling device of corn harvester

A corn harvester and peeling roller technology, which is used in harvesters, agricultural machinery and implements, agriculture, etc., can solve the problems of husk and leaf peeling rate, grain breakage rate, and grain loss rate, which is difficult to coordinate, and the research on ear feeding speed is not in-depth. Issues not yet covered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following specific embodiments are used to illustrate the embodiments of the present invention. Those who are familiar with the technology can easily understand other advantages and effects of the present invention from the contents disclosed in this specification. Obviously, the described embodiments are part of the present invention. , not all examples. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

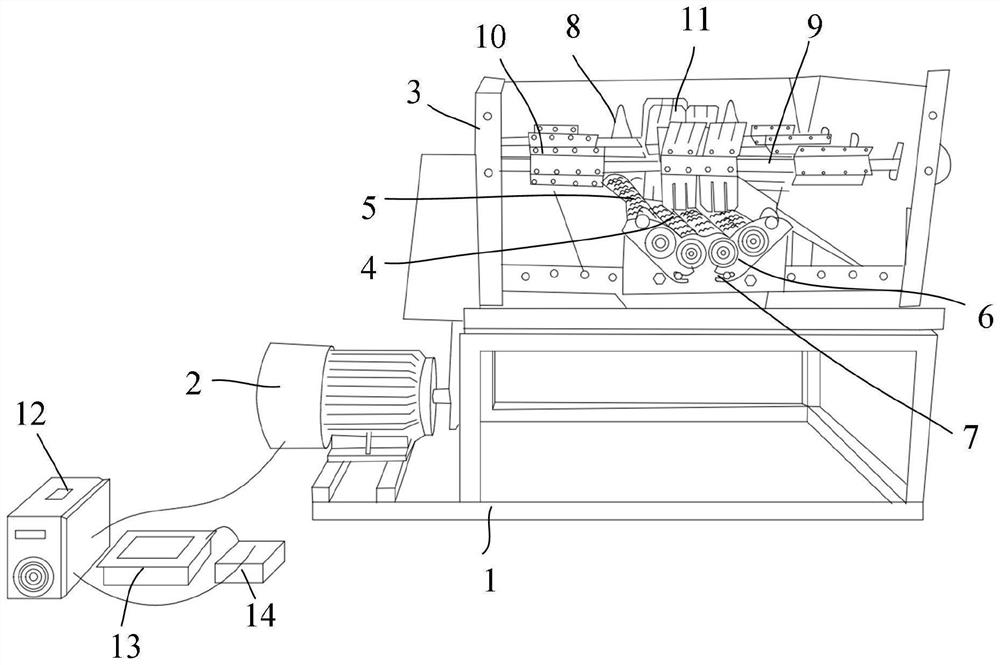

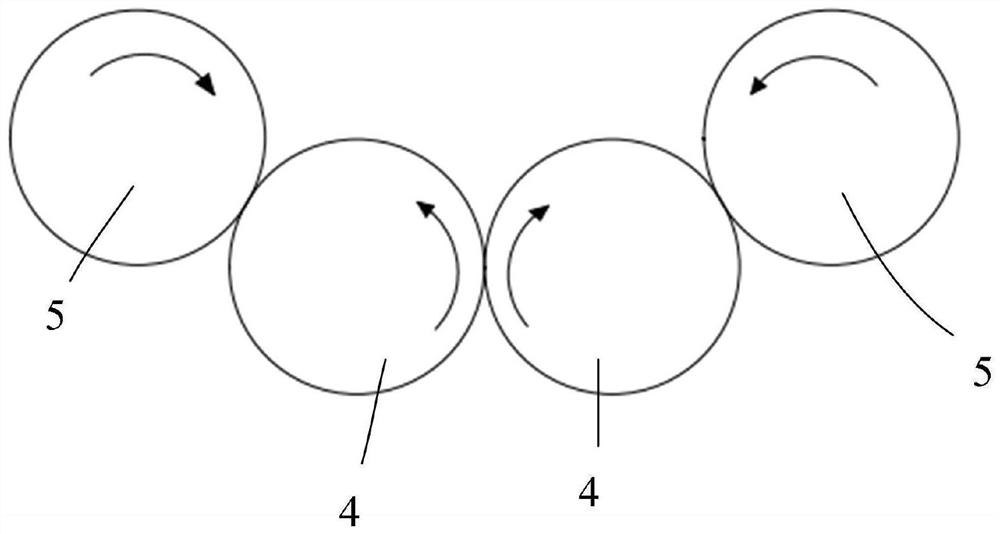

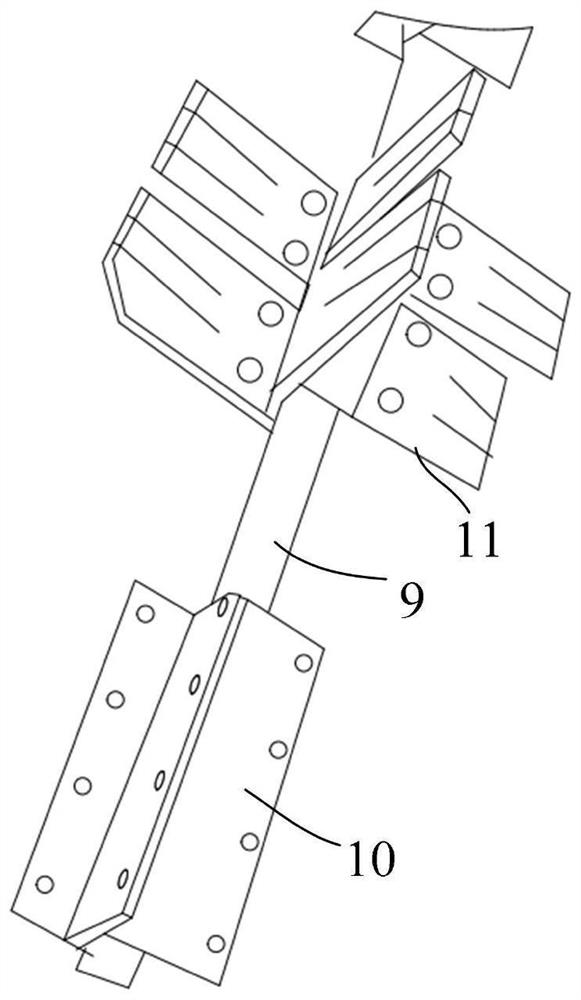

[0031] like Figure 1 to Figure 7 As shown, a corn harvester peeling device in the embodiment of the first aspect of the present invention includes a frame 1, a driving motor 2, an outer cover 3, a first peeling roller 4, a second peeling roller 5, a pressure feeder, and a belt drive. Components and bevel gear box; a cover 3 is installed above the frame 1, and one end of the cover 3 close to the frame 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com