Ceramic vessel

A technology of utensils and ceramics, applied in container cultivation, chemical instruments and methods, applications, etc., can solve the problems of observation, cleaning trouble, plants can not breathe oxygen, etc., to improve the utilization rate and ensure the effect of clean and tidy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

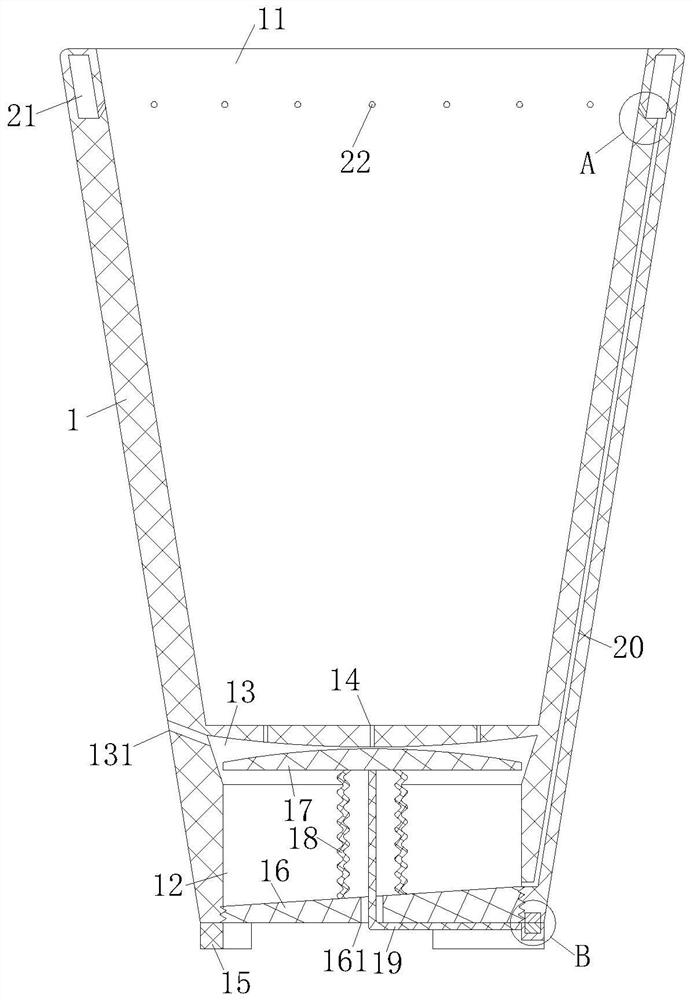

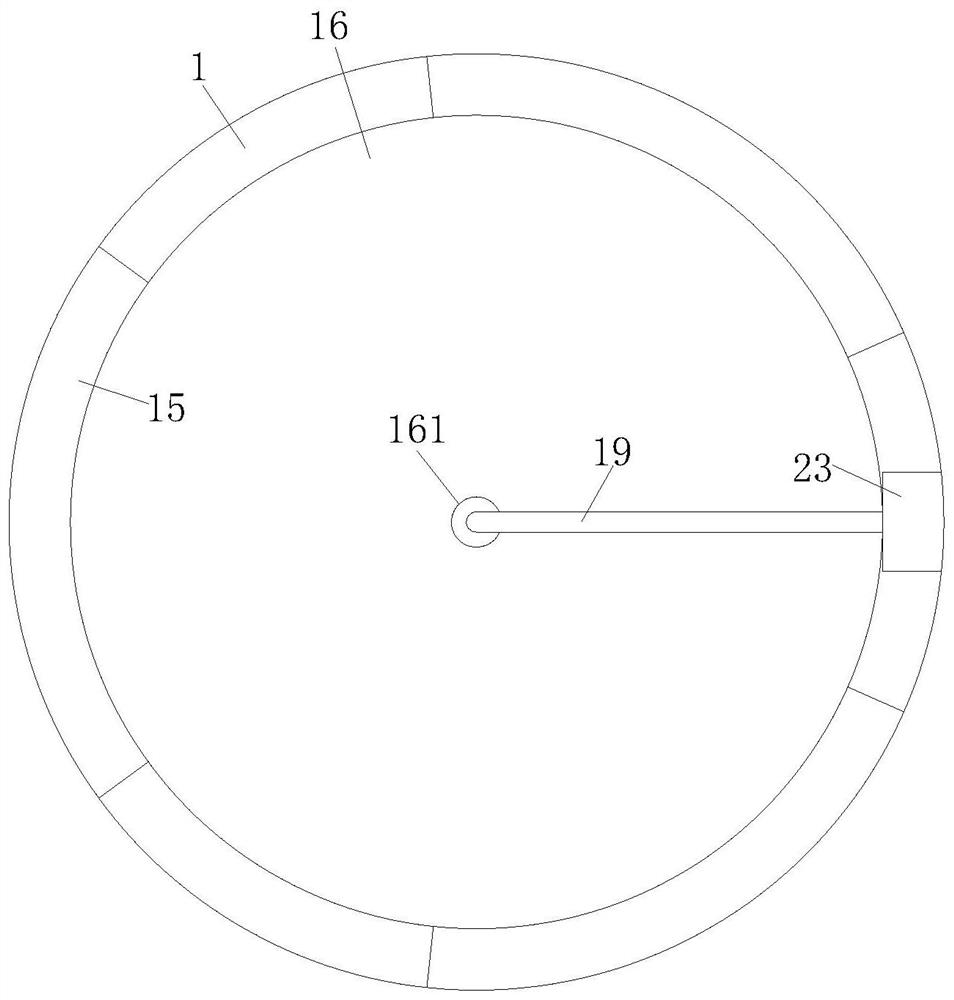

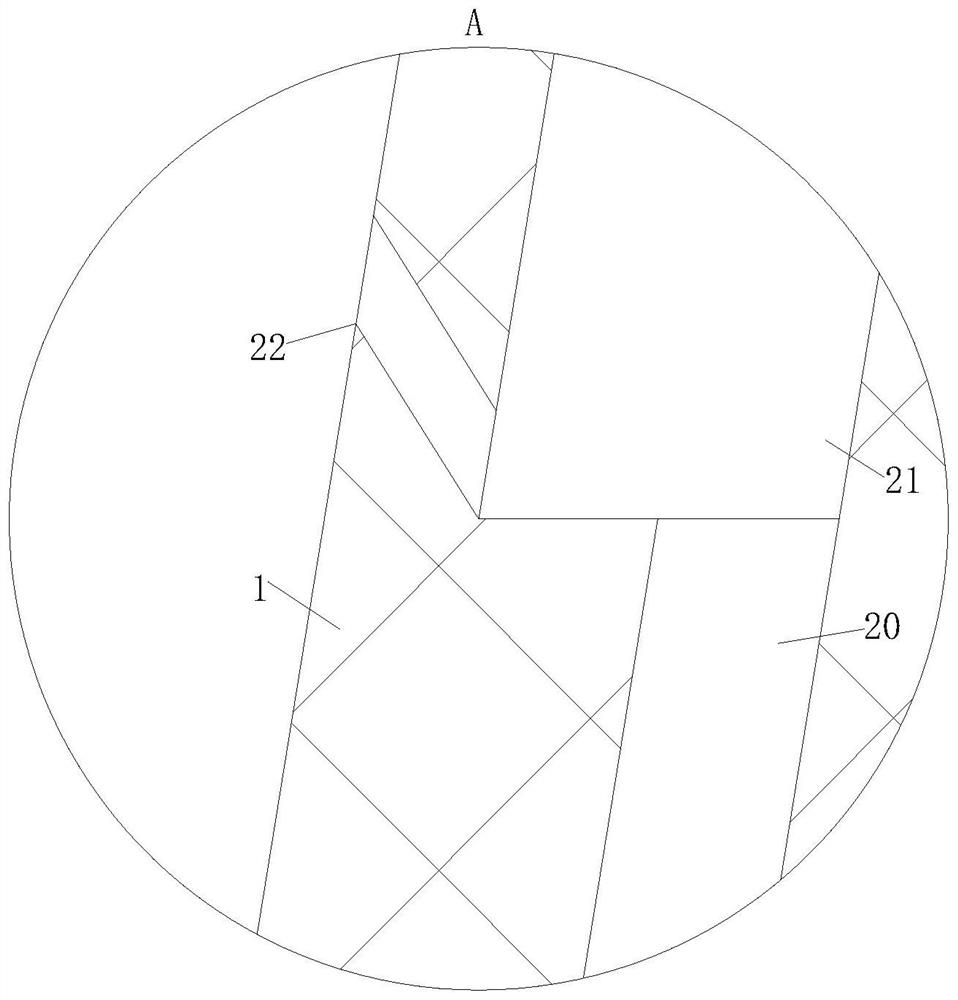

[0043] As a specific embodiment of the present invention, the lower end of the basin body 1 is provided with a support foot 15; the middle part of the basin bottom 16 is provided with an air outlet 161; the elastic member is an elastic bag 18; the driving unit is a pull rope 19; One end of the pull rope 19 is fixedly connected with the circular plate 17, and the other end is fixed to the bottom of the basin body 1 through the air outlet 161; the elastic bag 18 is sleeved on the place where the pull rope 19 is located. On one side of the water storage cavity 12, one end of the elastic bag 18 is fixedly connected with the circular plate 17, and the other end is fixedly connected with the basin bottom 16;

[0044] During work, when the plants in the pot body 1 need to be watered, the pull rope 19 is pulled, and the pull rope 19 drives the circular plate 17 to slide down along the side wall of the water storage cavity 12, and the water stored in the water storage cavity Squeezed b...

specific Embodiment approach

[0052] As a specific embodiment of the present invention, the upper end surface of the water guide groove 13 is an arc surface that protrudes from the edge to the middle;

[0053] When working, when the water source flows from the cultivation room 11 to the water guide trough 13 through the water outlet 14, the water will flow along the upper end face of the water guide trough 13, which is raised from the edge to the middle, from the periphery of the end face to the middle, and as it adheres to the water guide groove. 13 The accumulation of water droplets in the middle of the upper end surface is getting bigger and bigger, and will eventually drop on the upper end surface of the circular plate 17 under the influence of gravity, and finally roll down into the water storage cavity 12;

[0054] By setting the upper end surface of the water guide trough 13 as an arc surface that protrudes from the edge to the middle, compared with a flat surface, it is possible to avoid the situati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com