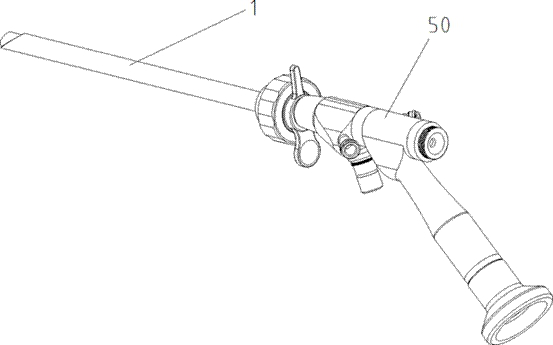

Spine endoscope safety working sheath capable of rapidly converting perfusion pressure

A fast conversion, endoscope technology, applied in the field of medical devices, can solve the problems of increased operation difficulty, complicated operation, and no setting, etc., and achieve the effect of reducing the difficulty of operation operation, simple device structure, and small size difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

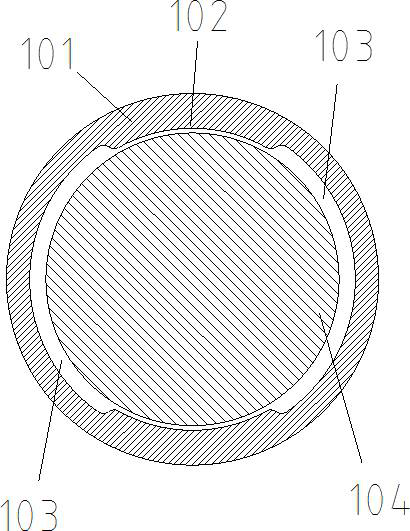

[0054] Further, as image 3 and 4 As shown, the conversion structure includes a valve 8, the valve 8 is cylindrical, the valve 8 is arranged in the middle of the conducting cylinder 2, and is located between the embedding groove and the end cover 4, The axial direction of the valve 8 is parallel to the axial direction of the sheath tube 1, and one side of the valve 8 is provided with a drainage hole 3 passing through the valve 8. The drainage hole 3 in the embodiment 1 is an oblong hole for drainage, so The axial direction of the drainage hole 3 is parallel to the axial direction of the sheath tube 1, and a small groove 6 is provided between the drainage hole 3 and the sheath tube embedding groove for discharging the flowing water from the water channel 103 into the casing. To the drain hole 3 , the end cover 4 is provided with a drain port 7 communicating with the drain hole 3 .

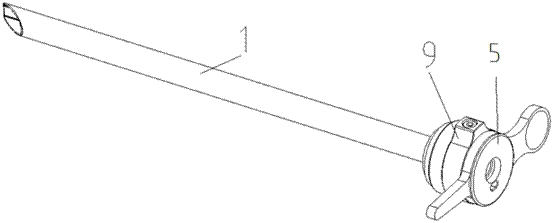

[0055] Further, the conversion control assembly also includes a stop knob 9, the stop knob 9 i...

Embodiment 2

[0060] like Figure 5-Figure 7 As shown, the conduction cylinder 2 in this embodiment is a multi-segment cylinder, the outer cylindrical surface of the uppermost segment is fixedly installed with the handle 5, and the cylindrical surface of the middle segment is provided with a plurality of drainage holes 3, such as Figure 7 As shown, a U-shaped chute 14 is arranged below the drainage hole 3, and the sheath tube 1 is installed in the last section; the water valve 13 is cylindrical as a whole, and one end is provided with a plurality of drainage ports 7, and the outer surface of the lower end of the drainage port 7 is provided with anti-skid The pin I15 is installed in the U-shaped groove on the outer surface of the conduction cylinder 2 and can move along the U-shaped chute 14; the spring 16 is located on the end face of the inner hole of the water valve 13, the spring cover 17 is used to fix the bottom of the spring, and the spring cover 17 is fixedly installed on one end of...

Embodiment 3

[0066] like Figure 8-Figure 10 As shown in the figure, a plurality of drainage holes 3 are arranged around the conducting cylinder 2 near the handle 5 , and a sliding groove 26 is provided on the side of the drainage hole 3 away from the handle 5 . A sliding pin 20 is provided, and the sliding pin 20 is slidably connected with the sliding groove 26; the conversion structure includes a knob 23, and the knob 23 is movably sleeved on the outer side of the conduction cylinder 2, and the knob 23 side The wall is provided with a plurality of drainage ports 7 communicating with the drainage holes 3 ; the inner wall of the knob 23 is also provided with a fixing groove 25 connected with the sliding pin 20 .

[0067] Further, a knob outer ring 22 is fixed on the outside of the knob 23 , and an elastic member 19 is provided between the knob outer ring 22 and the sliding pin. In this embodiment, the elastic member 19 is a spring. The two ends of the sliding groove 26 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com