Computer radiator die cutting device with automatic ash removal function

An automatic dust cleaning and radiator technology, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve problems affecting processing efficiency, affecting the stability of electronic equipment, etc., to prevent excessive movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0041] like Figure 1-10 As shown, this application provides:

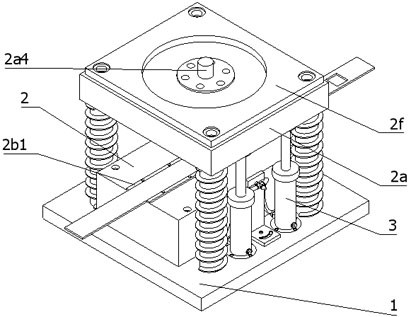

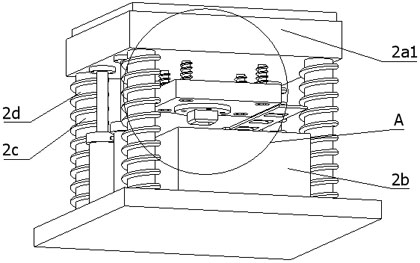

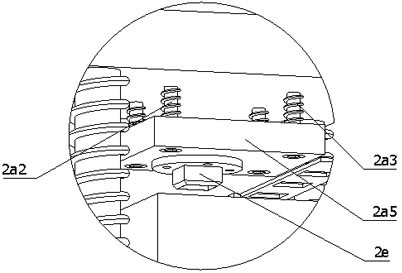

[0042] A computer radiator die-cutting device with automatic ash cleaning function, comprising a workbench 1, a die-cutting module 2 and a ash-cleaning module 3, the die-cutting module 2 includes a pressing die 2a, a fixed die 2b, a first guide post 2c, a A spring 2d and a cutter 2e; the fixed die 2b is fixedly installed on the workbench 1 by bolts, the first guide post 2c has multiple groups and is evenly distributed around the fixed die 2b, and one end face of the first guide post 2c is fixedly installed on the workbench 1, the other end face of the first guide post 2c extends vertically toward the surface away from the workbench 1, the die 2a is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com