Film covering device for tablet computer cover plate production and processing

A technology for a tablet computer and a lamination device, which is applied in the field of lamination devices for the production and processing of tablet computer cover plates, can solve the problems of unfavorable rapid lamination of tablet computer cover plates, poor lamination effect, complex structure design, etc., and achieves high performance. Market application value, conducive to rapid lamination, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

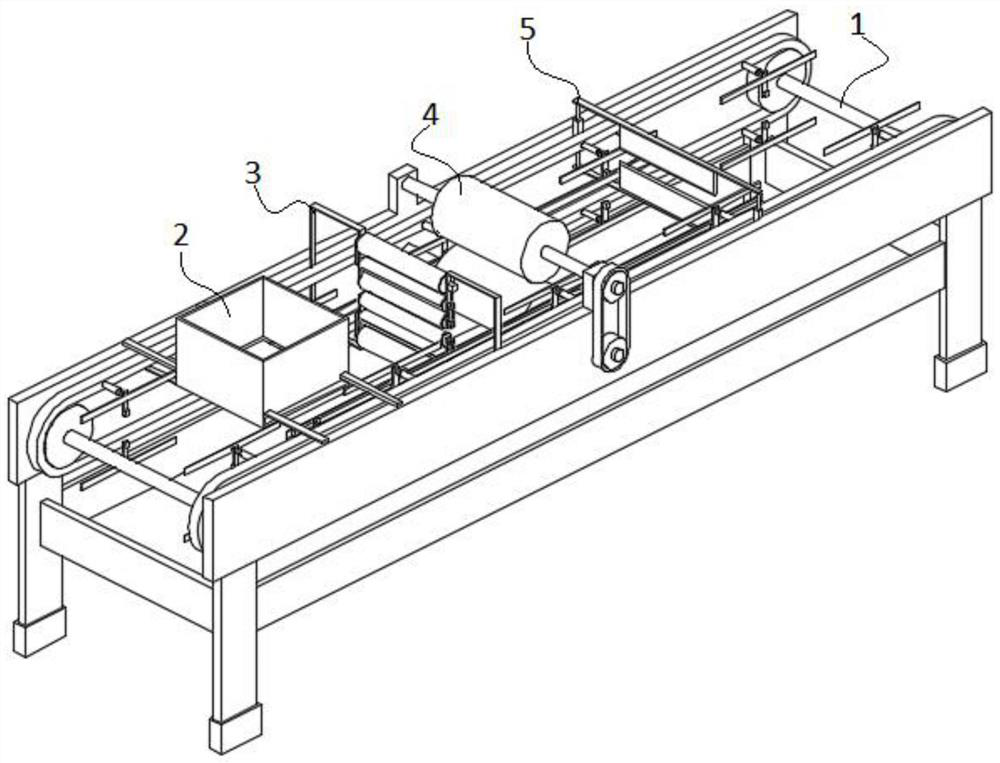

[0030] see figure 1 As shown in the figure, the present invention is a film coating device for the production and processing of a tablet computer cover, comprising a material transporting component 1; the upper part of the material transporting component 1 is provided with a feeding component 2, a dust cleaning component 3, a film coating component 4 and a Crop component 5. A cover plate is clamped from the feeding component 2 by the conveying assembly 1, and the conveying assembly 1 is used to drive the cover plate to pass through the dust cleaning assembly 3, the film covering assembly 4 and the cutting assembly 5 in sequence, so as to realize the covering operation of the cover plate. The structure design is reasonable, the operation is convenient, and the film coating efficiency of the cover plate is effectively improved, and the labor intensity of the workers is also reduced, which is beneficial to the rapid film coating of the tablet computer cover plate.

specific Embodiment 2

[0031] On the basis of the specific embodiment 1, the differences of this embodiment are:

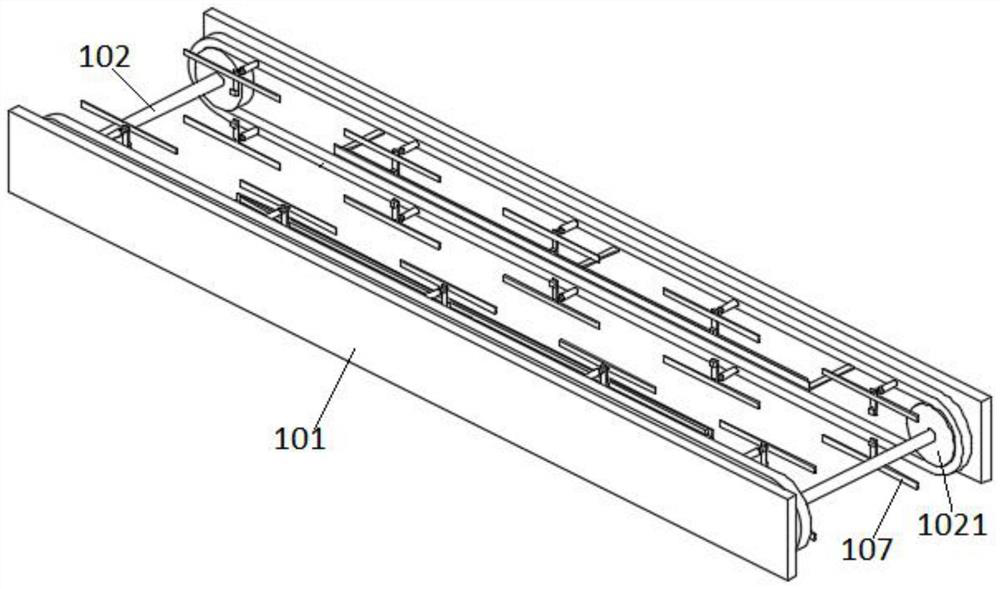

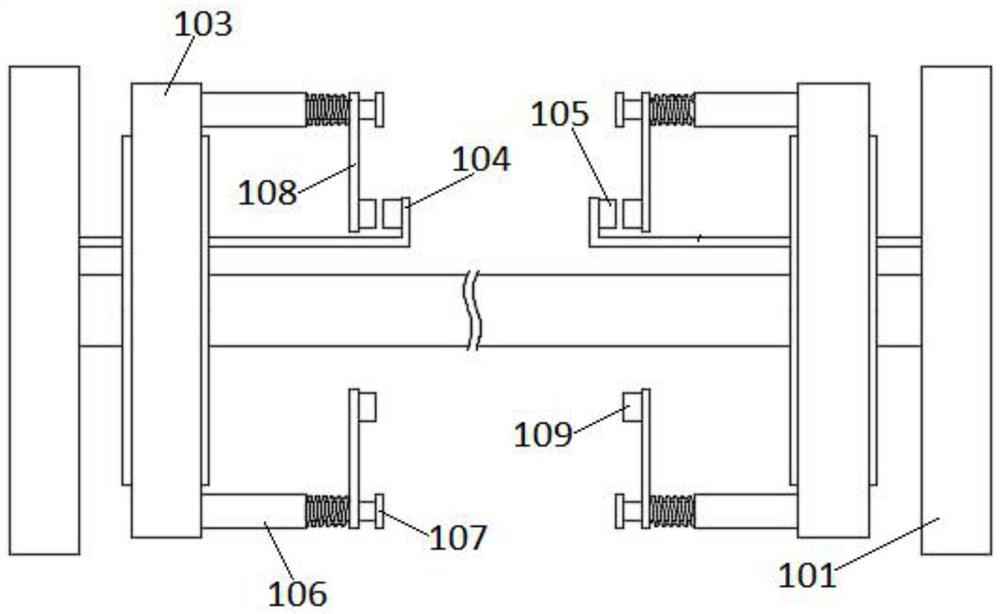

[0032] like Figure 2-3 As shown, the material transporting assembly 1 includes a pair of side support beams 101 arranged side by side; a pair of first drive shafts 102 arranged side by side are rotatably installed between the side support beams 101; one end of a first drive shaft 102 is fixed to a motor The motor is fixed on the side support beam 101; a pair of conveyor pulleys 1021 are fixed side by side on the first drive shaft 102; A pair of first brackets 104 are symmetrically fixed between the two material conveying belts 103; a magnetic strip 105 is fixed on the first bracket 104 along the length direction of the side support beam 101; the opposite inner sides of the two material conveying belts 103 are A plurality of elastic telescopic rods 106 arranged side by side are vertically fixed along the length direction; the elastic telescopic rod 106 is composed of a rod cylinder, a ...

specific Embodiment 3

[0033] On the basis of the second specific embodiment, the differences of this embodiment are:

[0034] like Figure 4-5As shown, the feeding assembly 2 includes a storage box 201 erected between two material conveying belts 103; a plurality of cover plates are stacked in the storage box 201 in turn; the upper and lower ends of the storage box 201 are open structures ; One opposite two side walls of the storage box 201 are respectively fixed on the support beams 101 on both sides through a plurality of supporting rods 202 arranged side by side; the bottom of the storage box 201 is horizontally fixed with a bearing plate 203; the bearing plate 203 and the storage box A feeding space 204 is formed between the lower ends of the feeding space 201; only one cover plate can be accommodated in the feeding space 204; hydraulic cylinders 206 are respectively arranged on opposite sides of the feeding space 204; the tail ends of the two hydraulic cylinders 206 are respectively vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com