Bidirectional coding device for plate production

A plate production, vertical technology, applied in transportation and packaging, object destacking, printing and other directions, can solve the problems of workers prone to mental fatigue, increased plate production costs, weak slab structural strength, etc., to reduce manpower. Cost input, good applicability, fast coding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

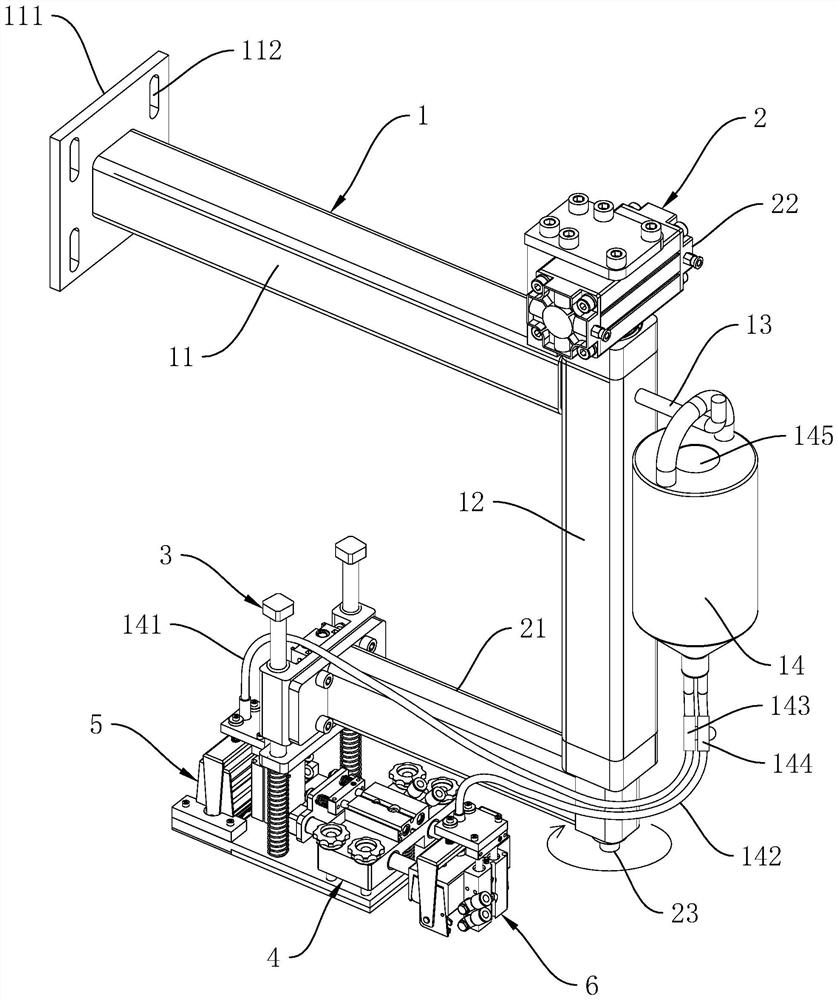

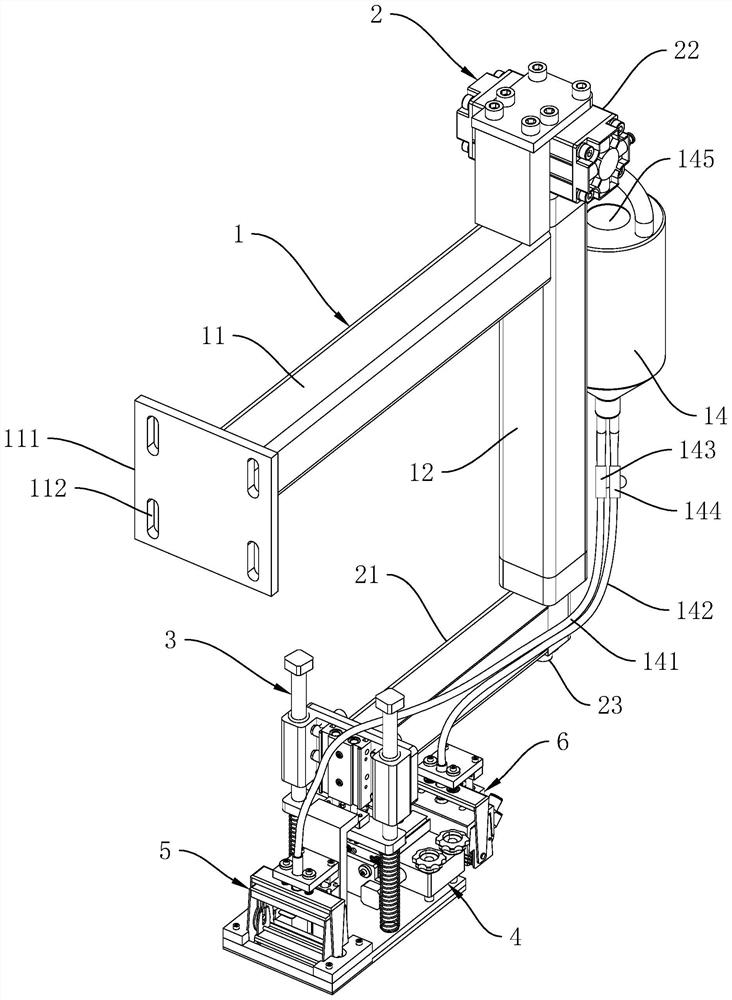

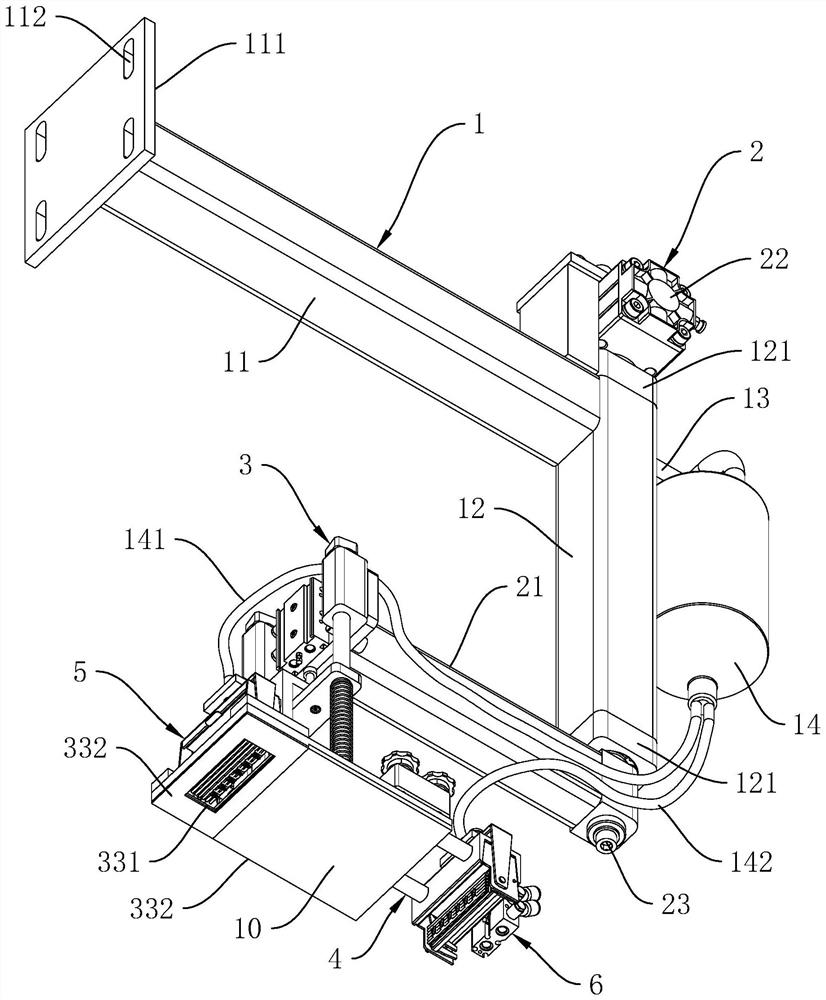

[0030] like Figure 1 to Figure 5 As shown in the figure, a bidirectional coding device for plate production according to the present invention includes a frame 1, a horizontal rotation mechanism 2, a lifting buffer mechanism 3, a horizontal telescopic buffer mechanism 4, a horizontal coding mechanism 5, and a vertical coding mechanism. 6. The horizontal rotation mechanism 2 is arranged on the frame 1, the rotating end of the horizontal rotation mechanism 2 is provided with a rotating swing arm 21, the lifting buffer mechanism 3 is arranged on the rotating swing arm 21, and the horizontal telescopic buffer The mechanism 4 is arranged on the lifting end of the lifting buffer mechanism 3, the horizontal marking mechanism 5 is arranged on the lifting end of the lifting buffer mechanism 3, and the marking end of the horizontal marking mechanism 5 is facing down, and the vertical marking mechanism 5 is set on the lifting end of the lifting buffer mechanism 3. The coding mechanism 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com