Advanced treatment and recycling equipment for printing and dyeing wastewater

A technology for advanced treatment of printing and dyeing wastewater, which is applied in textile industry wastewater treatment, water/sewage treatment, multi-stage water/sewage treatment, etc. It can solve the problems of long-term accumulation, blockage of isolation nets, and many organic pollutants, so as to avoid accumulation Effects of clogging and length reduction of nylon fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

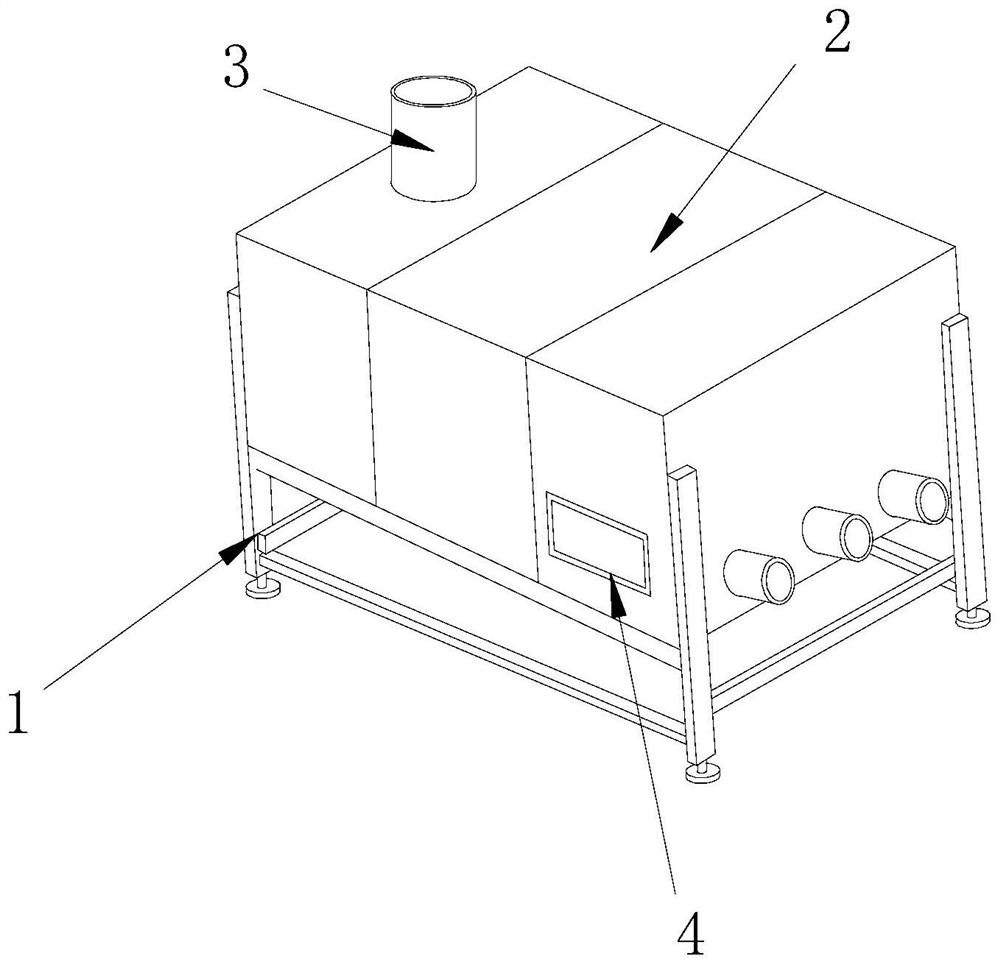

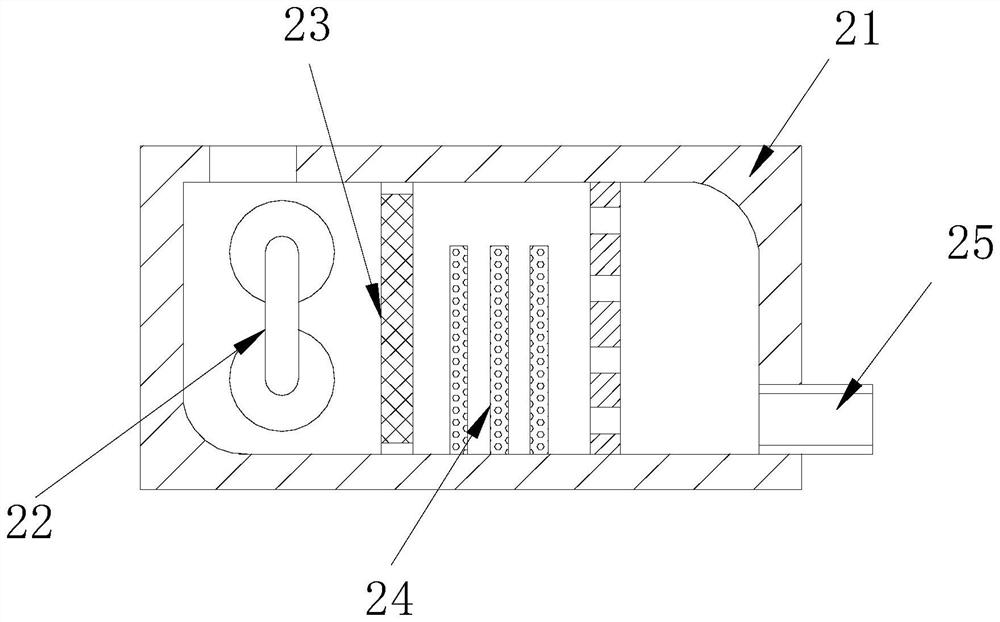

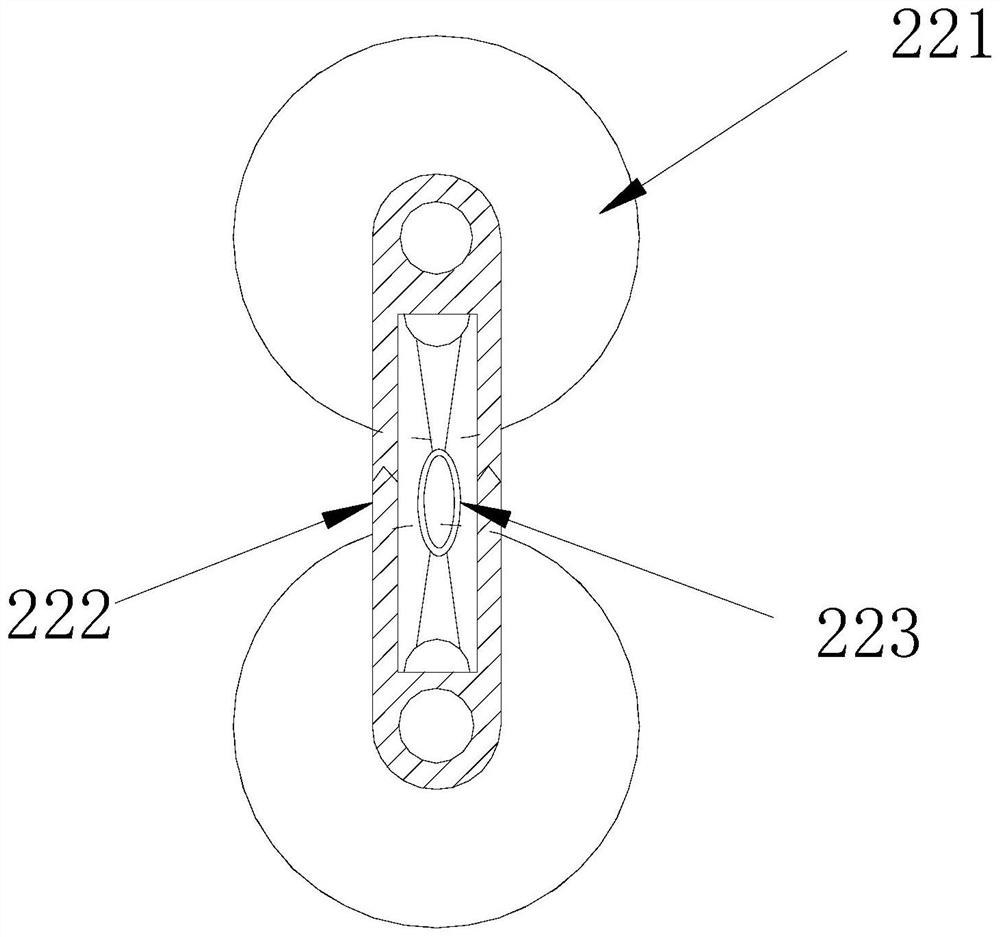

[0029] see Figure 1-Figure 6 , the specific embodiment of the present invention is as follows: a kind of advanced treatment and reuse equipment for printing and dyeing wastewater, its structure includes a base 1, a processor 2, an input pipe 3, a monitoring screen 4, and the top of the base 1 is welded to the left and right sides of the processor 2, The bottom surface of the input pipe 3 and the top surface of the processor 2 are connected to each other and are embedded and connected, and the monitoring screen 4 is embedded in the front surface of the processor 2; Column 24 and discharge pipe 25, the inner layer of the outer shell 21 is embedded and connected with the middle section of the tangent frame 22, the upper and lower sides of the filter plate 23 are embedded and connected with the inner layer of the outer shell 21, and the bottom surface of the reaction column 24 is embedded in the inner layer of the outer shell 21. , the left side of the discharge pipe 25 and the r...

Embodiment 2

[0036] see Figure 7-Figure 9 , the specific embodiment of the present invention is as follows: the shredding ring B4 includes an outer ring B41, an elastic wheel B42, a force block B43, and a telescopic head B44, and the inner layer of the outer ring B41 is movably connected to the back of the telescopic head B44, so The force block B43 is embedded in the outer layer of the outer ring B41, the outer layer of the telescopic head B44 is embedded and fixed with the bottom of the telescopic head B44, the center of the elastic wheel B42 is embedded and fixed with the inner layer of the processing tank B3, the force There are four blocks B43, and the gaps of the four force-receiving blocks B43 are evenly distributed on the right side of the outer ring of the outer ring B41, which is beneficial to twist the outer ring intermittently.

[0037] The telescopic head B44 includes a clamp head C1, a side block C2, a restriction strip C3, and an inner clamp block C4. The outer layer of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com