High-strength non-oriented silicon steel based on solution strengthening and preparation method thereof

An oriented silicon steel, solid solution strengthening technology, applied in the field of metallurgy, can solve the problem of high frequency iron loss, achieve the effect of excellent product performance, improved mechanical and magnetic properties, and wide thickness specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

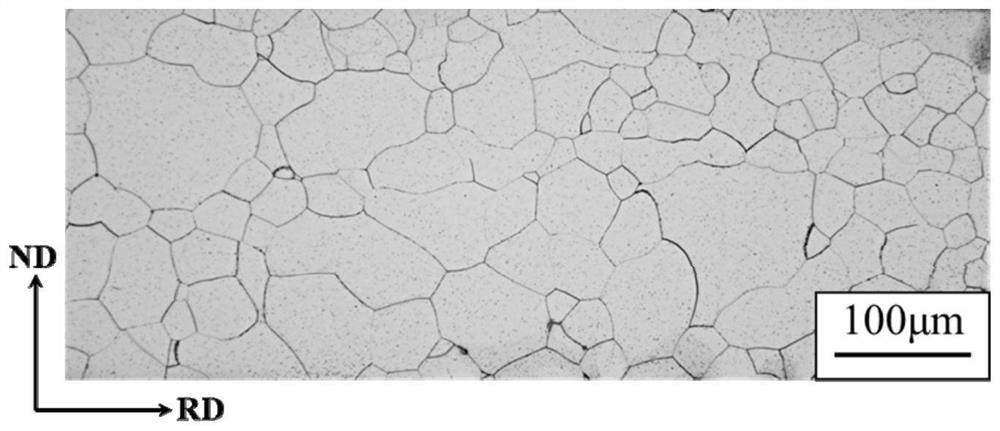

Image

Examples

preparation example Construction

[0032] In the specific implementation process, the present invention provides a method for preparing high-strength non-oriented silicon steel based on solid solution strengthening, including: vacuum smelting→casting and forging, hot rolling and normalizing heat treatment (or thin strip continuous casting)→pickling and cold rolling → Recrystallization annealing. When testing the performance of high-strength non-oriented silicon steel based on solid solution strengthening, the magnetic property test uses MATA magnetic material automatic testing system V4.0 to conduct magnetic measurement and data analysis and recording of experimental materials, and use MATS-2010M silicon steel measuring device to measure non-oriented silicon steel. Magnetic properties of silicon steel monoliths. Iron loss P 10 / 400 is the frequency of 400Hz alternating magnetic field, the specific total loss measured by the magnetic polarization at 1.0T, the magnetic induction B 50 is the magnetic polarization...

Embodiment 1

[0036] In the present embodiment, a method for manufacturing a conventional hot rolling process of high-strength non-oriented silicon steel based on solid solution strengthening, the specific steps are as follows:

[0037]1) Using raw materials with a purity of more than 99.99wt.%, smelting molten steel according to the set composition in a vacuum induction furnace, its chemical composition is: Si 4.8wt.%, P 0.05wt.%, Mn 0.1wt.%, Al 0.2 wt.%, C 36ppm, N 20ppm, O21ppm, S 12ppm, the rest are Fe. Under the condition of vacuum degree of 10Pa, vacuum degassing for 40min, smelting temperature is 1535℃, non-oriented silicon steel molten steel is obtained, cast into ingot and forged into billet at 1150℃.

[0038] 2) The billet then enters the heating furnace, the furnace temperature is 1150°C, the holding time is 120min, and the billet is hot rolled to a thickness of 2mm, and the final rolling temperature is 975°C.

[0039] 3) Carry out normalization heat treatment at 1100°C, and con...

Embodiment 2

[0045] In the present embodiment, a method for manufacturing a conventional hot rolling process of high-strength non-oriented silicon steel based on solid solution strengthening, the specific steps are as follows:

[0046] 1) Using raw materials with a purity of more than 99.99wt.%, smelting molten steel according to the set composition in a vacuum induction furnace, its chemical composition is: Si 4.5wt.%, P 0.10wt.%, Mn 0.3wt.%, Al 0.5 wt.%, C 32 ppm, N 23 ppm, O 18 ppm, S 13 ppm, rest Fe. Under the condition of vacuum degree of 10Pa, vacuum degassing for 40min, smelting temperature of 1500℃, to obtain non-oriented silicon steel molten steel, cast into ingot and forged into billet at 1125℃.

[0047] 2) The billet then enters the heating furnace, the heating furnace temperature is 1100°C, the holding time is 120min, and the billet is hot rolled to a thickness of 2mm, and the final rolling temperature is 950°C.

[0048] 3) Carry out normalization heat treatment at 1050°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

| Iron loss value | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com