Improved kiln with calcination observation mechanism

An improved kiln technology, applied in the field of kilns, can solve the problems of inability to observe the calcination situation of objects in real time and comprehensively, the kiln does not have an observation mechanism, and the control of calcination quality is poor, and achieves simple structure, fast and efficient regulation and control. , the effect of convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

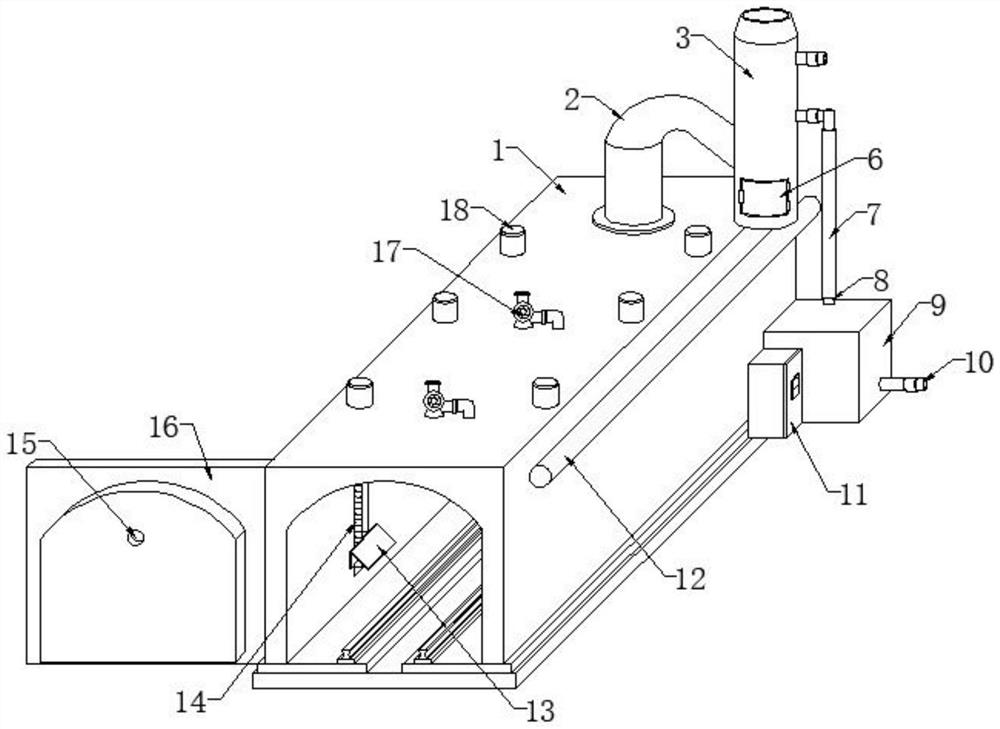

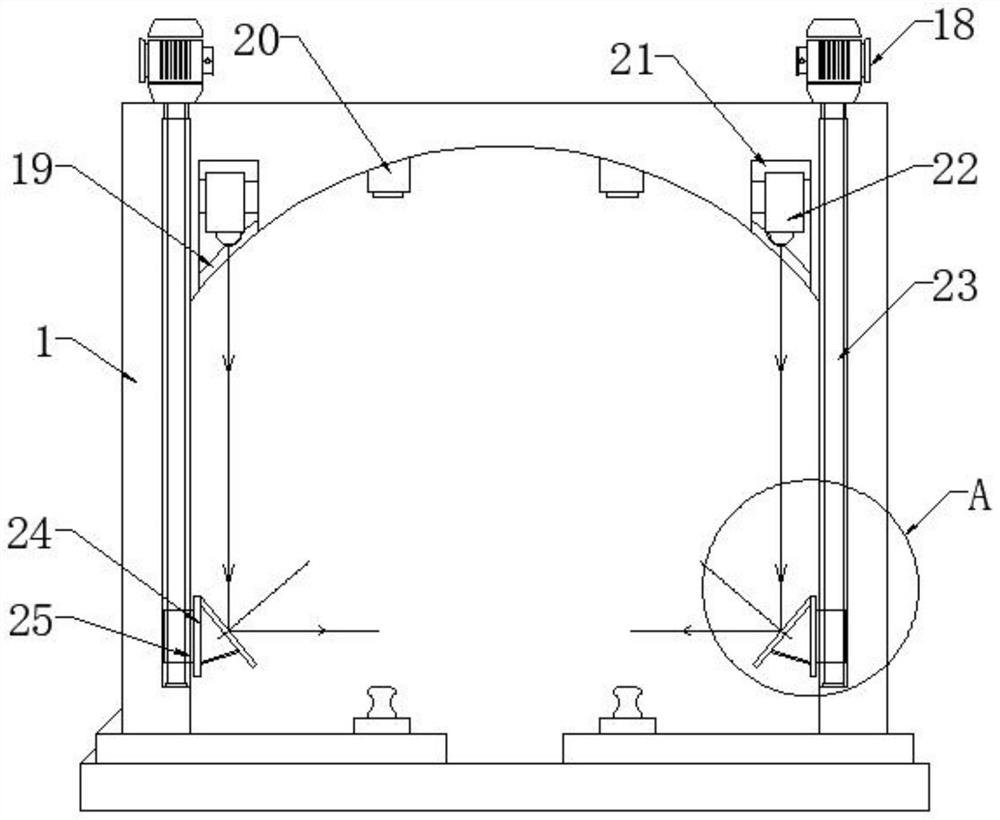

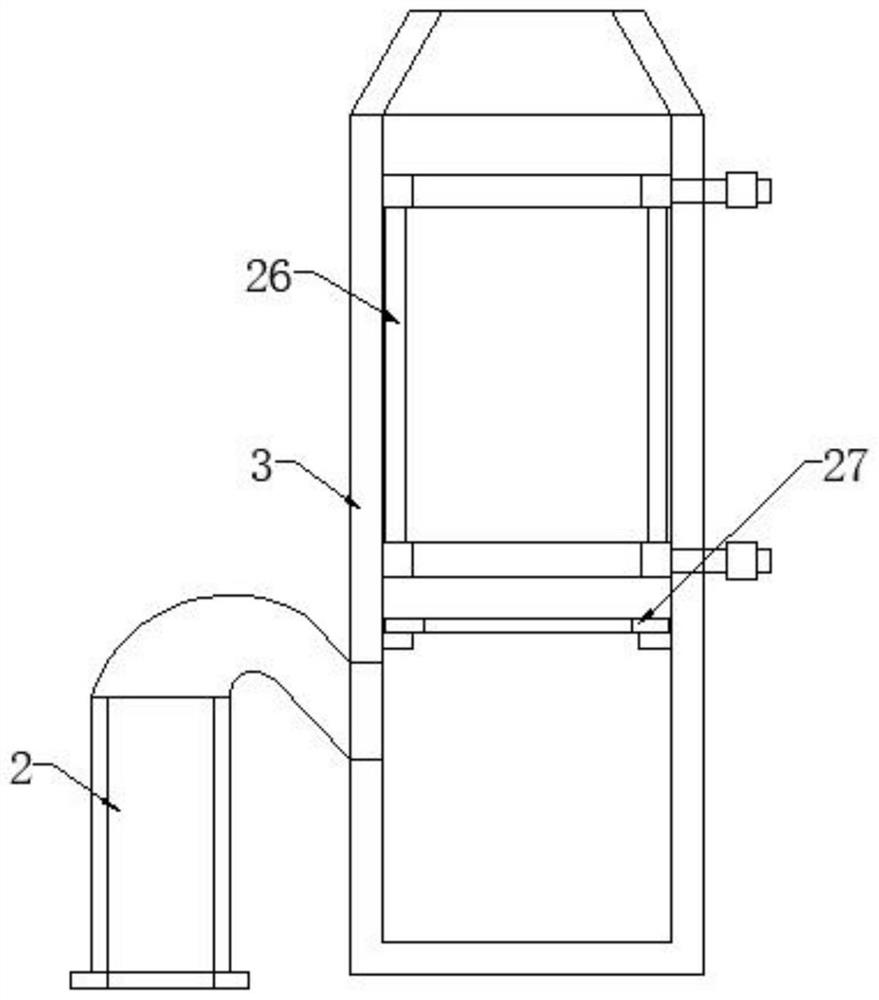

[0033] see Figure 1-9 , the present invention provides an improved kiln with a calcination observation mechanism, including a kiln furnace body 1, and a plurality of evenly distributed lifting chutes 14 are opened on both sides of the inner wall of the kiln furnace body 1. A ceramic screw 23 is rotatably connected to the inside of the chute 14 , a screw sliding sleeve 25 is threadedly connected to the middle of the plurality of ceramic screws 23 , and a support frame 24 is fixed on one side of the plurality of screw sliding sleeves 25 . One side of the 24 is fixedly provided with an observation frame plate 13, the surfaces of the plurality of observation frame plates 13 are fixedly provided with a high temperature resistant reflective plate 31, and both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com