Transfer case assembly optimization design method, transfer case assembly and engineering vehicle

An optimized design, transfer case technology, applied in the field of transfer case assembly and engineering vehicles, can solve the problems of potential safety hazards, heavy transfer case assembly, etc., achieve better performance, avoid abnormal noise of the transmission shaft failure, the effect of improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

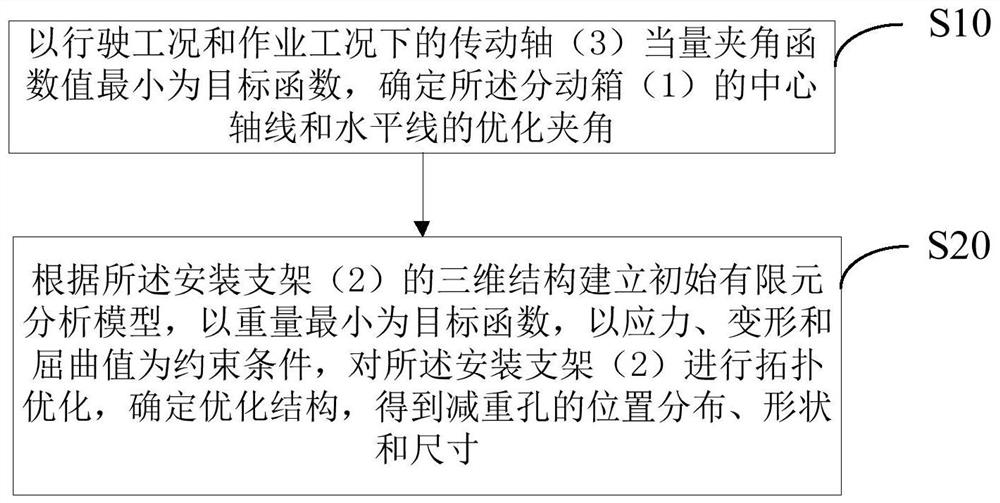

[0047] The optimal design method of the transfer case assembly according to the present invention will be described below with reference to the accompanying drawings.

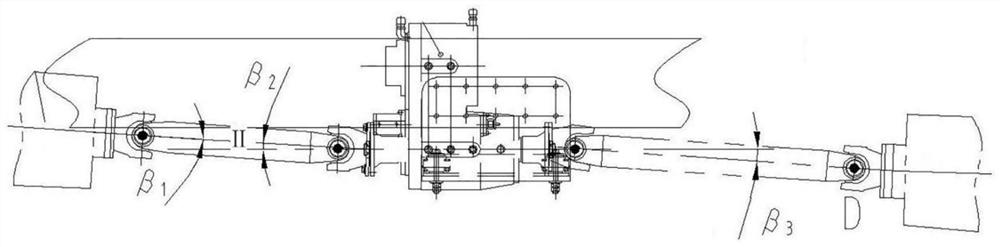

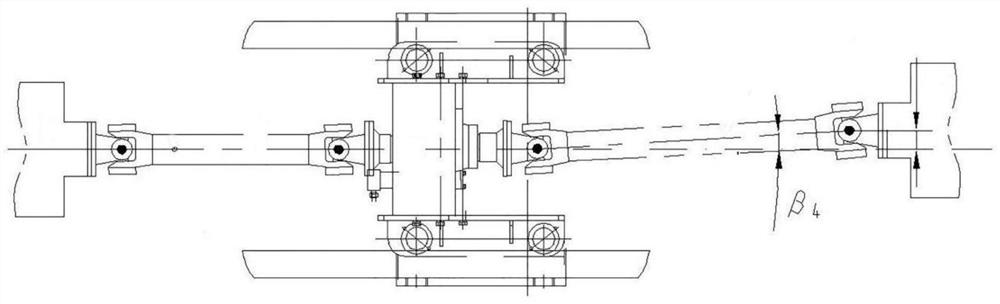

[0048] In an embodiment of the present invention, an optimal design method 100 for a transfer case assembly is provided, wherein the transfer case assembly 100 includes a mounting bracket 2 and a transfer case 1 mounted on the mounting bracket 2, so The two sides of the transfer case 1 are connected to one end of the transmission shaft 3 through the transmission universal joint 4, and the other end of the transmission shaft 3 is respectively connected to the gearbox 200 and the drive rear axle 300 through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com