Single automatic wire welding equipment for LED (light-emitting diode) lamp strip

An LED light strip and automatic welding technology, which is applied in the field of wire welding machines, can solve the problems of affecting the welding effect, the position deviation of the light strip, and the poor effect of the LED light strip limit, so as to improve the fixing strength, increase the limit strength, and improve The effect of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

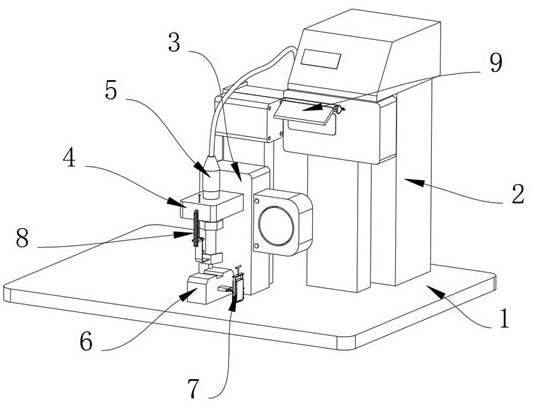

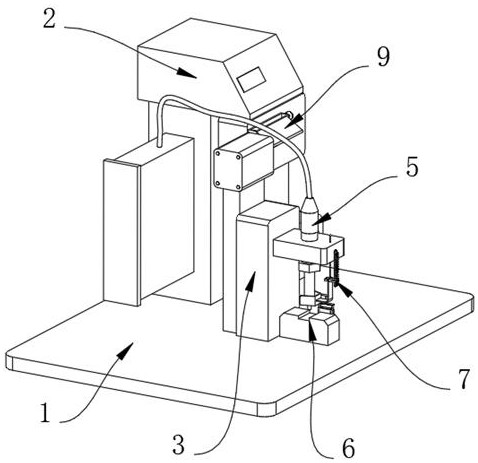

[0041] Example 1, as Figure 1-8 As shown, the present invention provides a single automatic wire bonding equipment for LED light strips, which includes a backing plate 1 and a limiting structure 7 . A workbench 3 is fixedly connected to the side, a support base 4 is installed on the surface of the workbench 3, a welded pipe 5 is installed in the support base 4, a base 6 is fixedly connected to the side of the backing plate 1 close to the welded pipe 5, and one side of the base 6 has a limit Positioning structure 7, the surface of the support base 4 is provided with a protective structure 8, and the surface of the manipulator 2 is provided with a shielding structure 9.

[0042] The specific settings and functions of the limiting structure 7 , the protective structure 8 and the shielding structure 9 will be described in detail below.

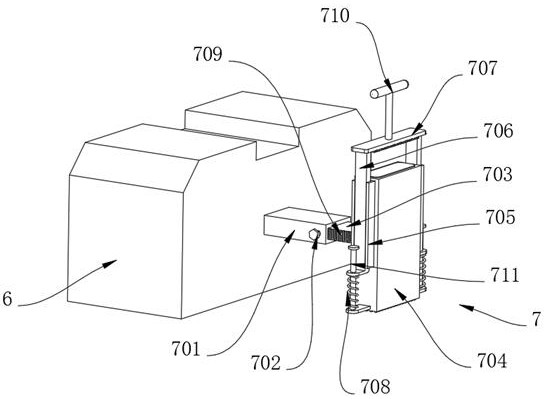

[0043] like image 3 and Figure 4 As shown, the limiting structure 7 includes a square tube 701, the square tube 701 is fixedly connected to...

Embodiment 2

[0049] Embodiment 2, on the basis of Embodiment 1, the shielding structure 9 includes a fixing frame 91, the fixing frame 91 is fixedly connected to the surface of the manipulator 2, the two arms of the fixing frame 91 are rotatably connected with a rotating rod 92, and the circle of the rotating rod 92 is rotatably connected. The arc surface is fixedly connected with a baffle plate 93, and one end of the rotating rod 92 is fixedly connected with a circular plate 94. The side of the circular plate 94 away from the rotating rod 92 is evenly provided with a number of card slots 95, and the fixing frame 91 is close to the side of the circular plate 94. A support frame 96 is fixedly connected, and a plug pin 97 is slidably inserted in the support frame 96. The size of the plug pin 97 is adapted to the size of the card slot 95 of the circular plate 94, so as to achieve the effect that the rotation angle of the baffle plate 93 can be quickly adjusted. 93 has the effect of blocking ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com