Crawler marching type large-flow drainage emergency vehicle

A traveling, high-flow technology, applied in the field of emergency vehicles, can solve the problems of large impurities and easy blockage of pipelines, and achieve the effect of improving functionality and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

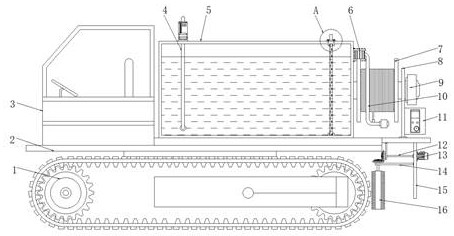

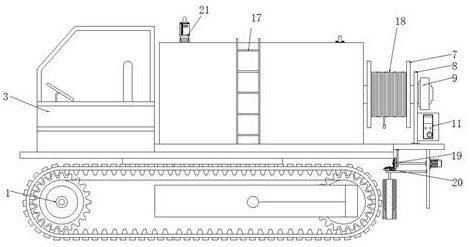

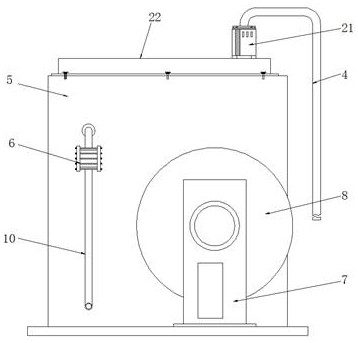

[0023] Example 1: see Figure 1-4 , a crawler traveling type large-flow drainage emergency vehicle, comprising crawler 1, a bottom plate 2 is installed on the top of the crawler 1, a cab 3 is installed on the left side of the top of the bottom plate 2, a water storage tank 5 is installed on the right side of the top of the bottom plate 2, The front end of one side of the water tank 5 is provided with a water pumping pipe 10, the top of the water pumping pipe 10 is equipped with a high-pressure water pump 6, one side of the water storage tank 5 is penetrated by a drain pipe 4, and the top of the drain pipe 4 is equipped with a drain pump 21, and the water storage tank 5 The front end is equipped with a ladder 17;

[0024] The top and bottom ends of the inner right side of the water storage tank 5 are provided with a limit seat 24, and a metal filter screen 25 is sleeved inside the limit seat 24. Connection, the bottom of the fixed plate 22 is installed with a top plate 23, the...

Embodiment 2

[0026] Embodiment 2: A mounting plate 15 is mounted on one side of the bottom of the base plate 2 , a second drive motor 13 is mounted on the top of the right side of the mounting plate 15 , a connecting shaft 12 is mounted on the top of the left side of the mounting plate 15 , and the left side of the connecting shaft 12 The first gear 19 is fixedly connected, the bottom of the left side of the mounting plate 15 is mounted with the support frame 14, the top of the support frame 14 is equipped with the second gear 20, the bottom of the first gear 19 is provided with the second gear 20, the first gear 19 and The second gears 20 form a mutually perpendicular relationship, the output end of the second drive motor 13 is connected to the connecting shaft 12, and the bottom of the second gear 20 is fixedly connected with the cleaning roller 16 through the connecting piece;

[0027] Specifically, as figure 1 , figure 2 and image 3 As shown, after the use of the connecting pipe 18...

Embodiment 3

[0028] Example 3: A support plate 8 is installed on one side of the top of the bottom plate 2, a winding roller 7 is installed between the water storage tank 5 and the support plate 8, and a connecting pipe 18 is wound on the winding roller 7, and the top of the right side of the support plate 8 is installed. A first drive motor 9 is installed, the output end of the first drive motor 9 is connected to the take-up roller 7, and a control box 11 is installed at the bottom of the right side of the support plate 8;

[0029] Specifically, as figure 1 and figure 2 As shown, when the crawler 1 is running, impurities are easily caught in the gap, and the second drive motor 13 is activated to drive the connecting shaft 12 to rotate. The connecting shaft 12 and the first gear 19 are fixedly connected, together with the first gear 19 and the second The gear 20 rotates, and the second gear 20 is used to drive the cleaning roller 16 to rotate, so as to clean the impurities in the gap of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com