Wrought aluminum alloy with high mechanical property and preparation method thereof

A technology for deforming aluminum alloys and mechanical properties, which is applied in the field of deformed aluminum alloys with high mechanical properties and its preparation, and achieves the effects of reducing the cost of the alloy, lowering the dosage, and improving the plasticity at room temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

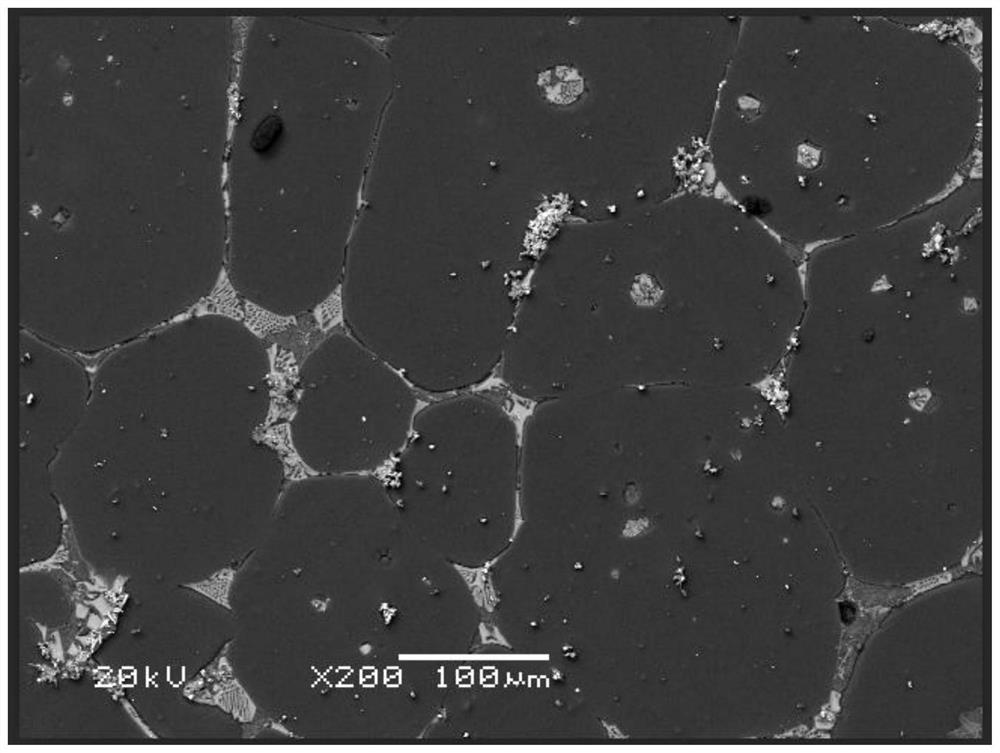

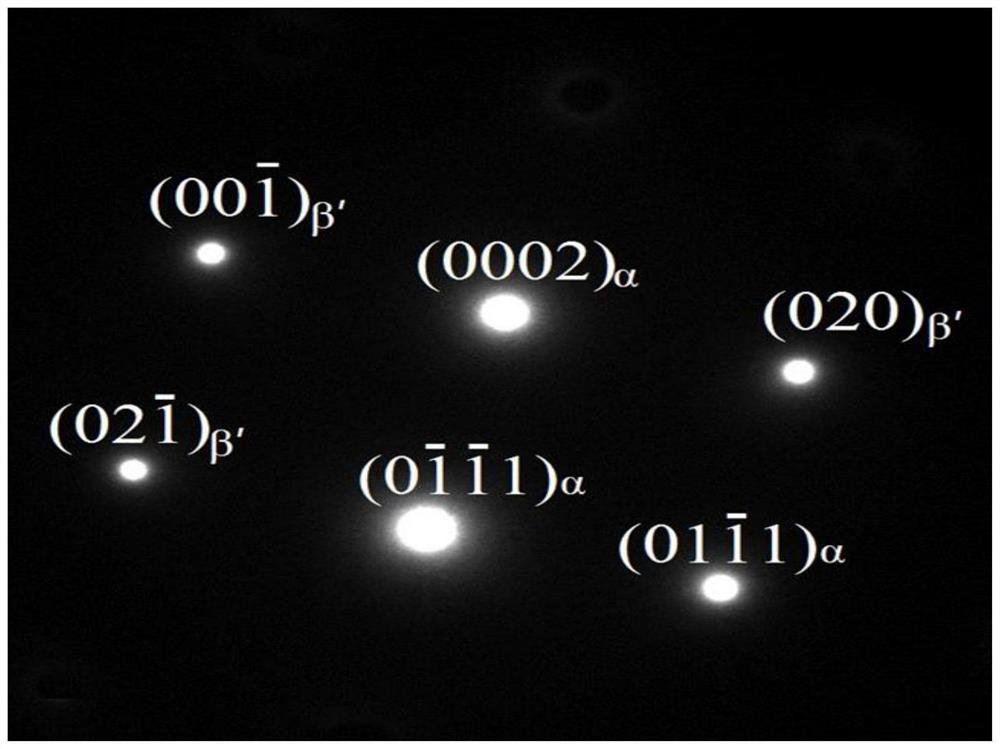

Image

Examples

Embodiment 1

[0028] Step 1: According to Mg1.5%, Si0.5%, Cu0.2%, Ce0.1%, the balance is the mass percentage of Al, and pure aluminum, pure magnesium and master alloy Al-20Si, master alloy Al -25Cu, master alloy Al-30Ce preheated to 250℃;

[0029] Step 2: Open the smelting furnace, place pure aluminum in the crucible, raise the furnace temperature to 710°C, wait for the pure aluminum to melt, raise the temperature to 760°C, add pure magnesium and master alloy Al-20Si, master alloy Al-25Cu, master alloy Al-30Ce is melted and mixed uniformly to form a melt; after the melt is allowed to stand for 30min, the refining process is carried out, and then it is poured into a preheated casting mold to melt and cast to obtain the aluminum alloy ingot;

[0030] Step 3: perform high temperature homogenization treatment on the as-cast aluminum alloy obtained in step 2 in a heat treatment furnace, with a heating rate of 20°C / min, heating to 480°C, holding for 24 hours, and air-cooling the ingot to room tem...

Embodiment 2

[0037] Step 1: According to Mg2.0%, Si1.0%, Cu0.5%, Ce0.2%, the balance is the mass percentage of Al, and pure aluminum, pure magnesium and master alloy Al-20Si, master alloy Al -25Cu, master alloy Al-30Ce preheated to 250℃;

[0038] Other process steps are the same as in Example 1.

Embodiment 3

[0040] Step 1: According to Mg2.5%, Si1.5%, Cu0.9%, Ce0.3%, the balance is the mass percentage of Al, and pure aluminum, pure magnesium and master alloy Al-20Si, master alloy Al -25Cu, master alloy Al-30Ce preheated to 250℃;

[0041] Other process steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com