Optical fiber angle sensor and preparation method thereof

An angle sensor and optical fiber sensing technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of difficult to obtain high sensitivity, low measurement sensitivity, difficult to manufacture, etc., to avoid being worn or contaminated. , good sensing sensitivity, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

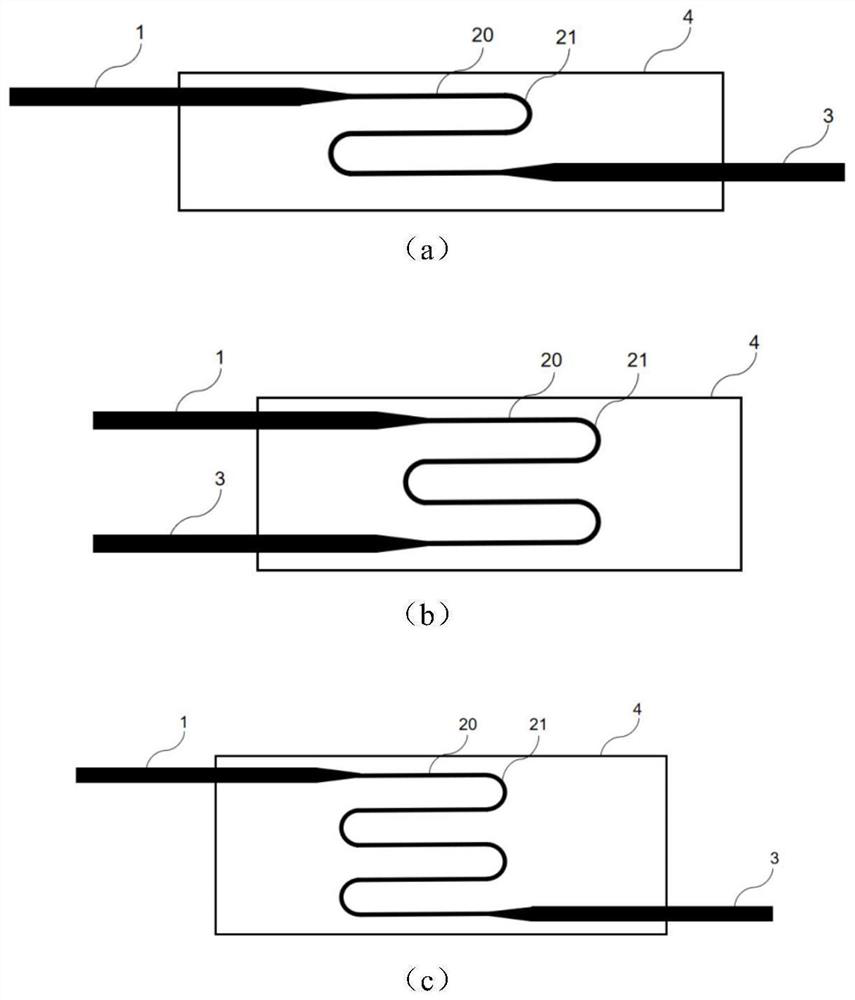

[0042] The preparation method of the flexible packaging unit according to the embodiment of the present invention specifically includes the following steps:

[0043] S1: First, mix the stock solution and the curing agent at a ratio of 10:1 and stir to remove air bubbles to obtain a PDMS sol. Then spin the PDMS sol on a glass slide. After curing, a PDMS film is obtained. The thickness of the film is 250-500 μm. .

[0044] S2: Second, place the multi-bending structure optical fiber sensing unit on the PDMS film, spin-coat a layer of PDMS sol, and then obtain the desired packaging structure after curing.

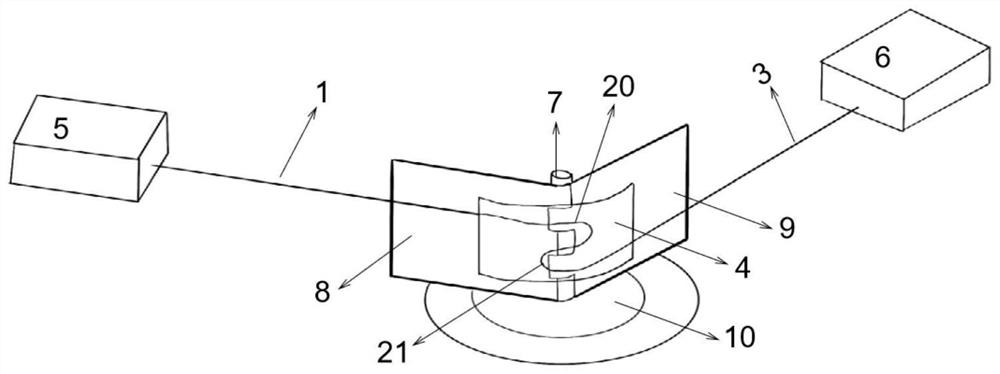

[0045] A preparation method of an optical fiber angle sensor according to an embodiment of the present invention includes:

[0046] S1: Place the optical fiber on the optical fiber fixture, preheat and stretch the heating mobile platform to obtain an optical fiber with a symmetrical tapered structure. The length of the tapered waist region of the tapered structure can be chang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com