Automatic batch testing device for chip capacitors and use method

A technology of batch testing and capacitors, which is applied in the direction of measuring devices, measuring device casings, and components of electrical measuring instruments, etc., can solve problems such as difficulty in satisfying automated testing, high detection capabilities, high operating requirements, and low detection efficiency, and achieve testing The results are effective and reliable, the accuracy is guaranteed, and the effect of easy loading, unloading, maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

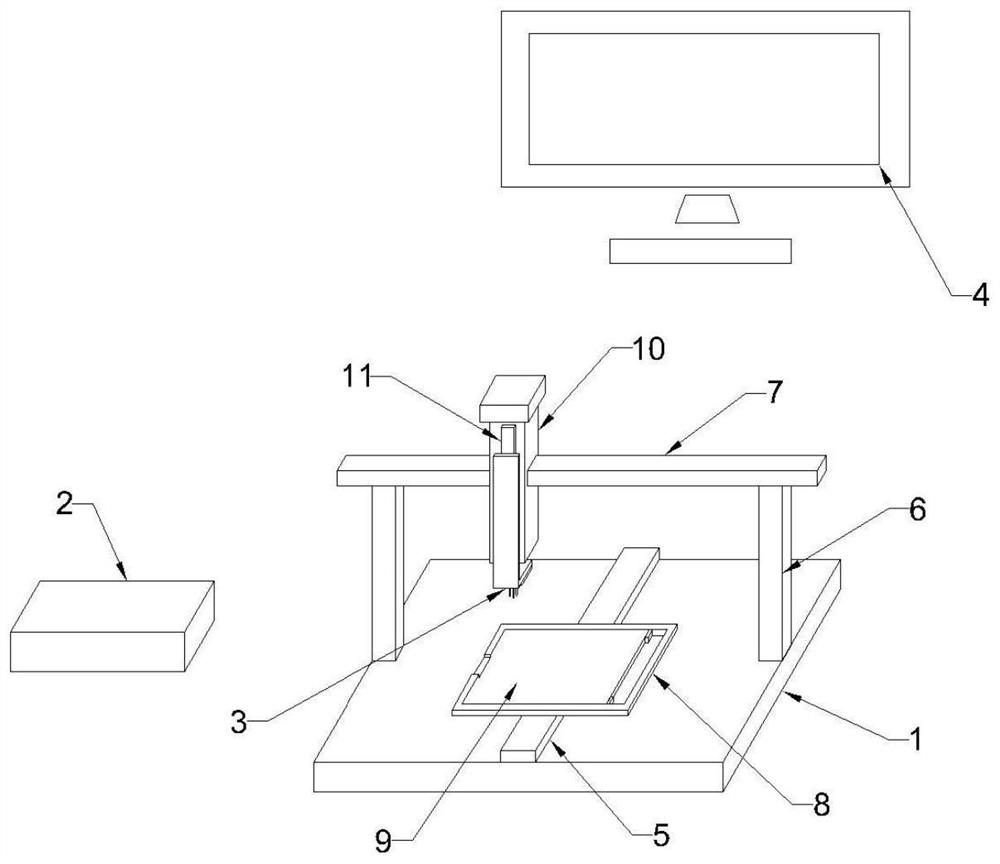

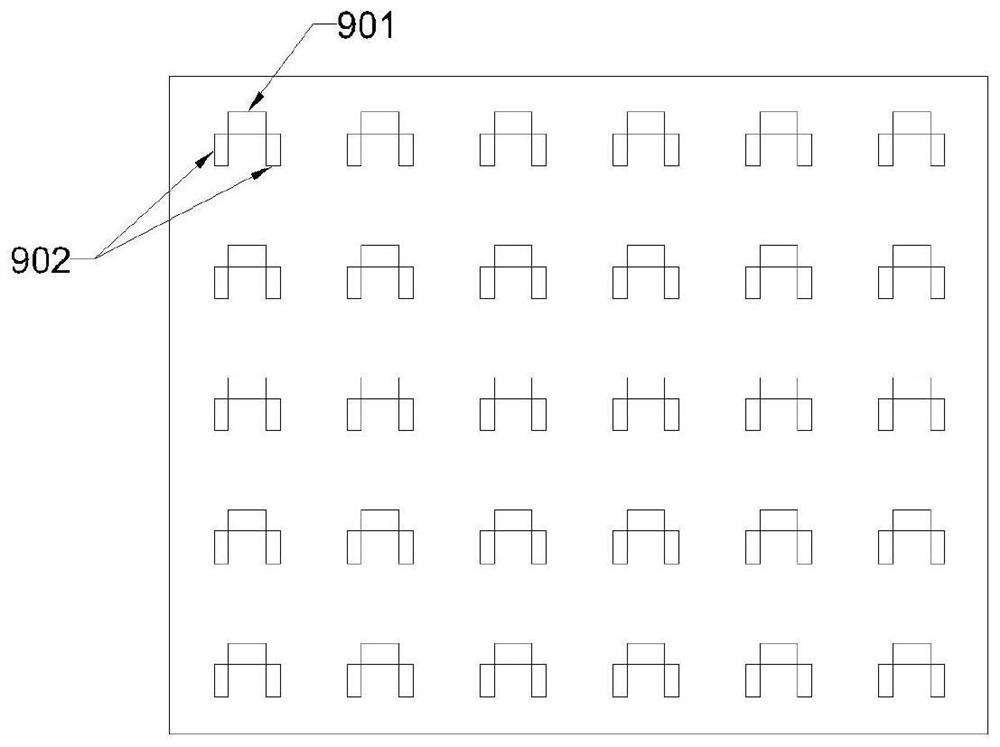

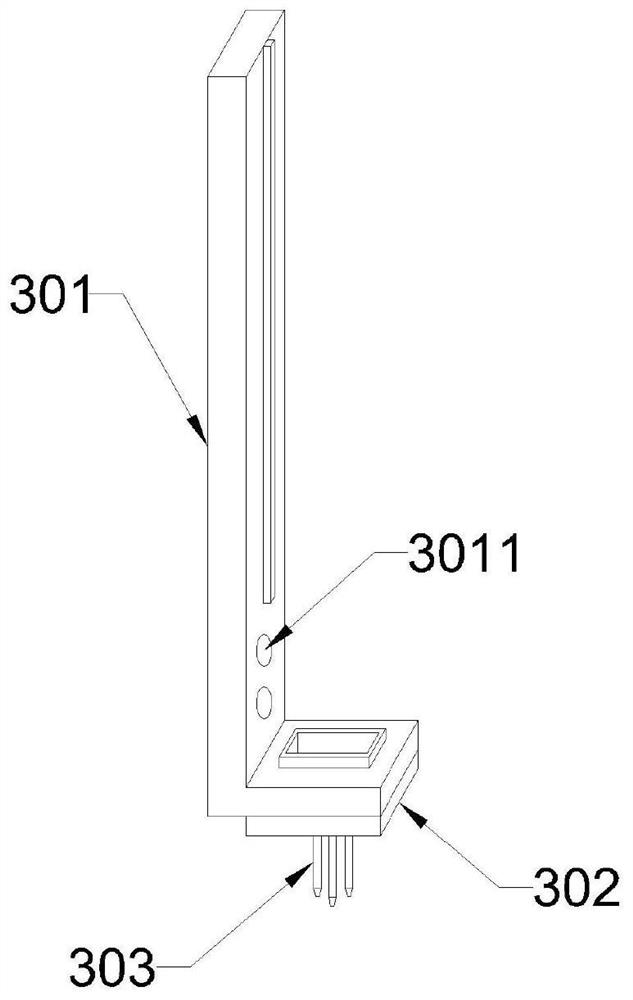

[0033] like Figure 1-5 As shown, an automatic batch testing device for chip capacitors includes a console 1, a testing instrument 2, a test terminal 3 and a computer 4, and the console 1 is provided with a slide rail 5 longitudinally in the middle of the table top, and the slide rail 1 The upper part of the 5 is provided with a sliding rail 2 7 horizontally through the bracket 6, the sliding rail 2 7 is perpendicular to the sliding rail 1 5, and the sliding rail 1 5 is slidably connected to the tray 8 for placing the capacitor test board 9. Several test stations are arranged in a matrix for placing the capacitors to be tested. The slide rail 2 7 is slidably connected to the slider 10. The slider 10 is provided with a slide rail 3 11 on the outer side. The slide rail 3 11 is slidably connected to the test end 3. The test end 3 is connected to the test instrument 2 and the test instrument 2 through wires. Electrically connected to the computer 4; the tray 8, the slider 10 and ...

Embodiment 2

[0041] A method for using an automatic batch testing device for chip capacitors, comprising the following processes:

[0042] S1: Set the palletizing statement through the computer software, and set the number of rows and columns of the test station matrix;

[0043] S2: Set the number of stacking strokes, and specify the priority axis for stacking;

[0044] S3: Set the stacking starting point and stacking spacing, formulate the arch trigger position, and prepare for operation;

[0045] S4: Run the test contact to reach the starting point of the stacking and send the in-position signal to start the test;

[0046] S5: Run the stacking point according to the stacking setting and complete the test.

[0047] Preferably, when the test data is zero or exceeds the set threshold range, each slide rail on the console executes a reset operation command to stop the test and return to the original position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com