Lightweight optimization method for motor rotor punching sheet

An optimization method and technology for motor rotors, which are applied in design optimization/simulation, electrical digital data processing, instruments, etc., can solve the problems of too simple and conservative structural rigidity checking, unfavorable lightweight design, and long design optimization cycle, and achieve The effect of performance and cost optimization, shortening product design time cycle, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the present invention is further described in detail below with reference to the accompanying drawings, but it does not constitute any limitation to the present invention.

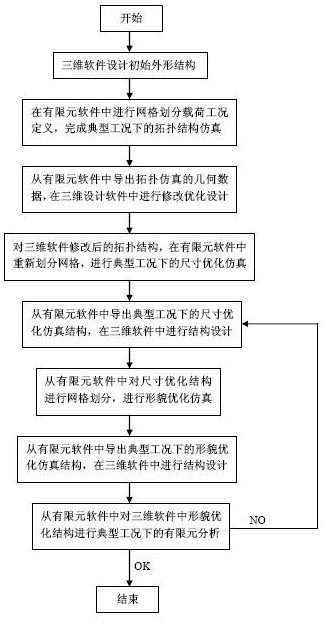

[0018] A lightweight optimization method for punching a motor rotor, which specifically includes the following steps:

[0019] Step 1. Use 3D design software to design the initial shape structure of a rotor punching piece;

[0020] Step 2. Perform topology optimization analysis under typical working conditions on the initial rotor punching structure in the finite element topology optimization software, and obtain the topology structure under comprehensive typical working conditions;

[0021] Step 3. Modify the design based on the topology of the rotor punch in the 3D design software;

[0022] Step 4. Perform size optimization analysis on the rotor punching topological structure designed by the three-dimensional software based on typical working c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com