Method for improving blasting tunneling footage by optimizing positions of cut holes and empty holes

A technology for blasting cutting footage and cutting holes, which is applied in design optimization/simulation, earth-moving drilling, mining equipment, etc., and can solve problems such as difficult blasting conditions and failure to achieve blasting effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

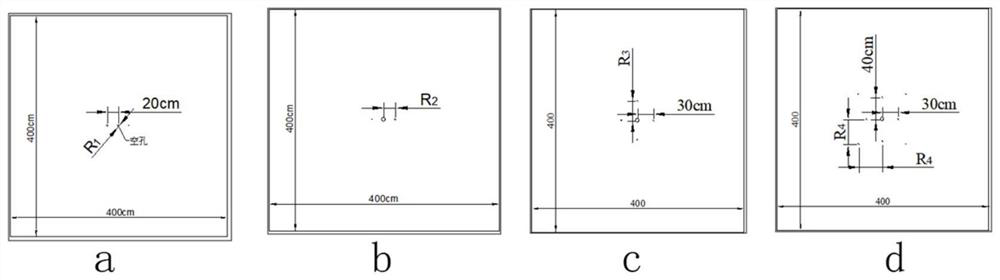

[0049] A method for optimizing the positions of undercut holes and empty holes to increase blasting footage, comprising the following steps:

[0050] S1. Selection of test site: The test site is Dahongshan Copper Mine, the ore rock of Dahongshan Copper Mine is mainly marble, and the rock mechanical parameters of marble are close to those used in numerical simulation.

[0051]S2. Selection of the diameter of the undercut hole and the hollow hole: the diameter of the undercut hole is 50mm, and the undercut hole is the charging hole for placing explosives. The hole diameter ratio needs to be greater than 1.7.

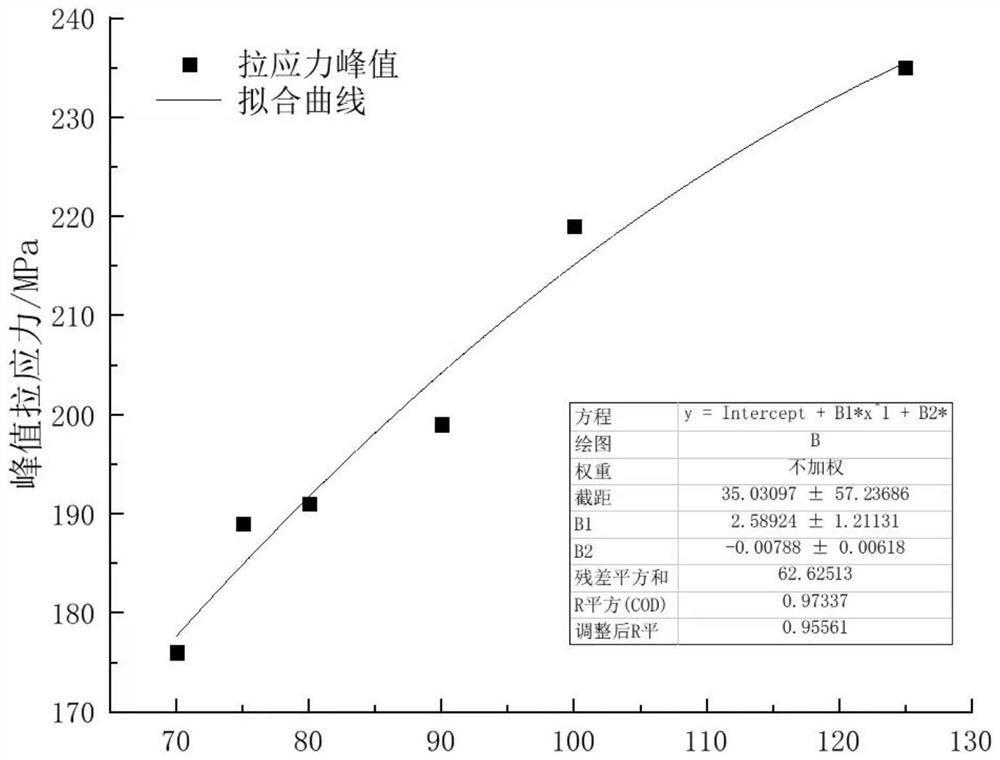

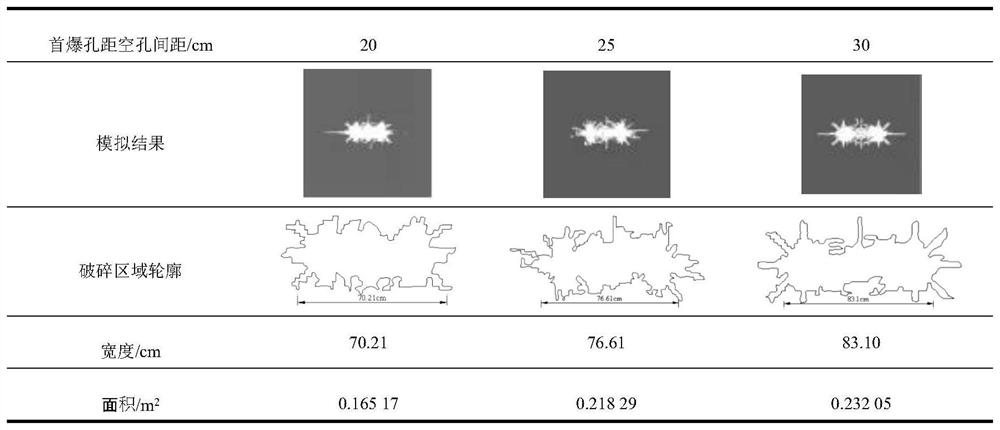

[0052] S3. Selection of the hole distance between the undercut hole and the hollow hole: the undercut hole is divided into the first blast hole, the second blast hole and the third blast hole. The distance between the first blast hole and the hollow hole is affected by the compensation space and the explosive crushing range. The first blast hole is blasted to form a groov...

Embodiment 2

[0071] A method for optimizing the positions of the undercut holes and the hollow holes to improve the blasting footage, on the basis of the first embodiment, in S2, the selection of the undercut holes and the hole diameters of the hollow holes satisfies the following formula:

[0072]

[0073] Among them: D is the diameter of the hollow hole; d is the diameter of the charge hole, α is the rock blasting fracture angle, D≥85mm, and when vertical cutting is used, α>30° is required.

[0074] It should be noted that, when the diameter of the hollow hole is larger than the diameter of the charging hole, and the formula (1) is satisfied, not only the rock between the hollow hole and the charging hole can be broken, but also a crushing funnel can be formed.

[0075] In S2, a large-diameter hollow hole is selected as the free surface, and the hollow hole is parallel to the charging hole in the free surface to form a sufficient compensation space.

[0076] In S3, the compensation sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com