OKKEN profile for high-voltage switch cabinet and heat treatment process of OKKEN profile

A technology for high-voltage switch cabinets and profiles, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of difficulty in meeting the load-bearing requirements of large protective plates and low strength of profiles, so as to improve the scope of application, improve the sound absorption effect, and reduce noise Diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

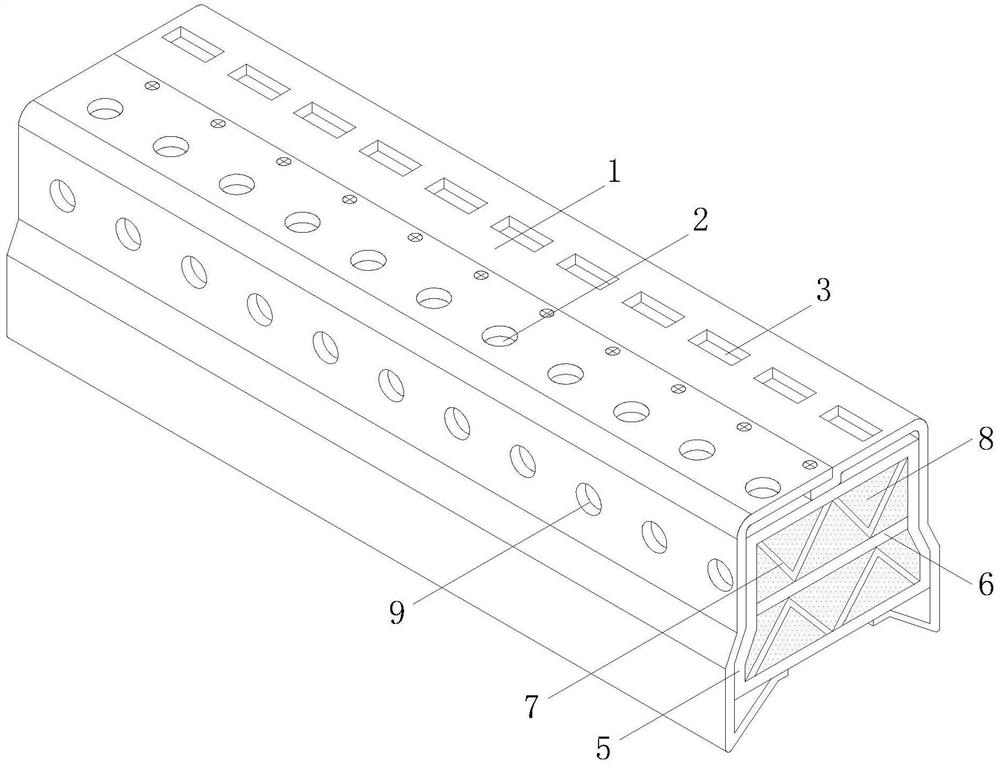

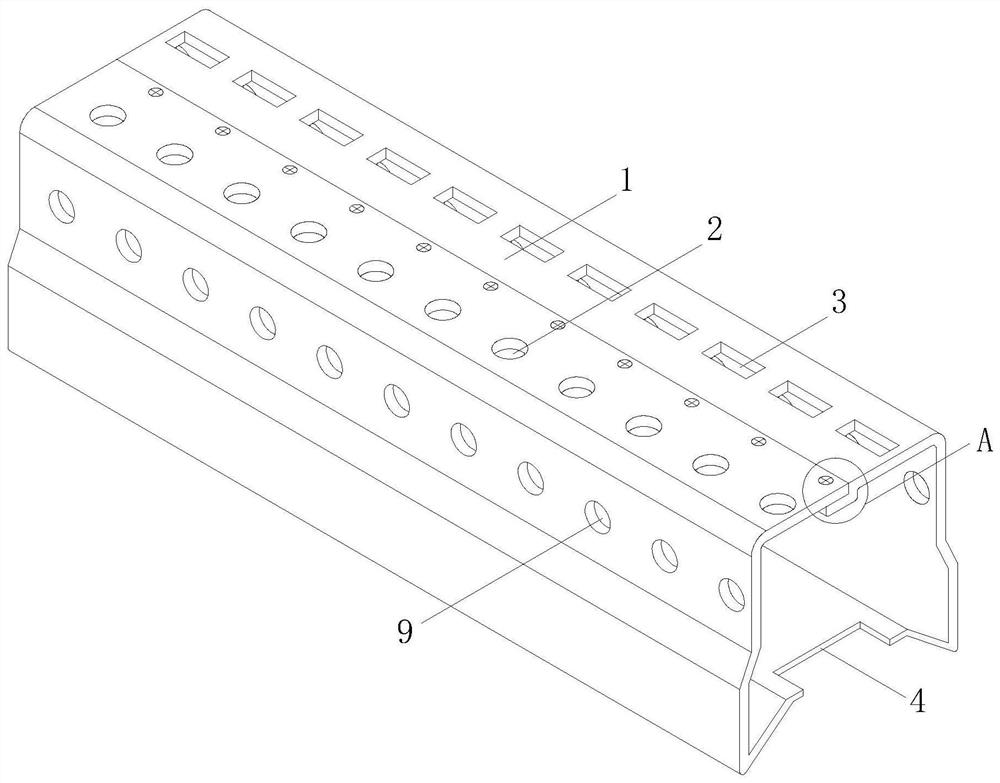

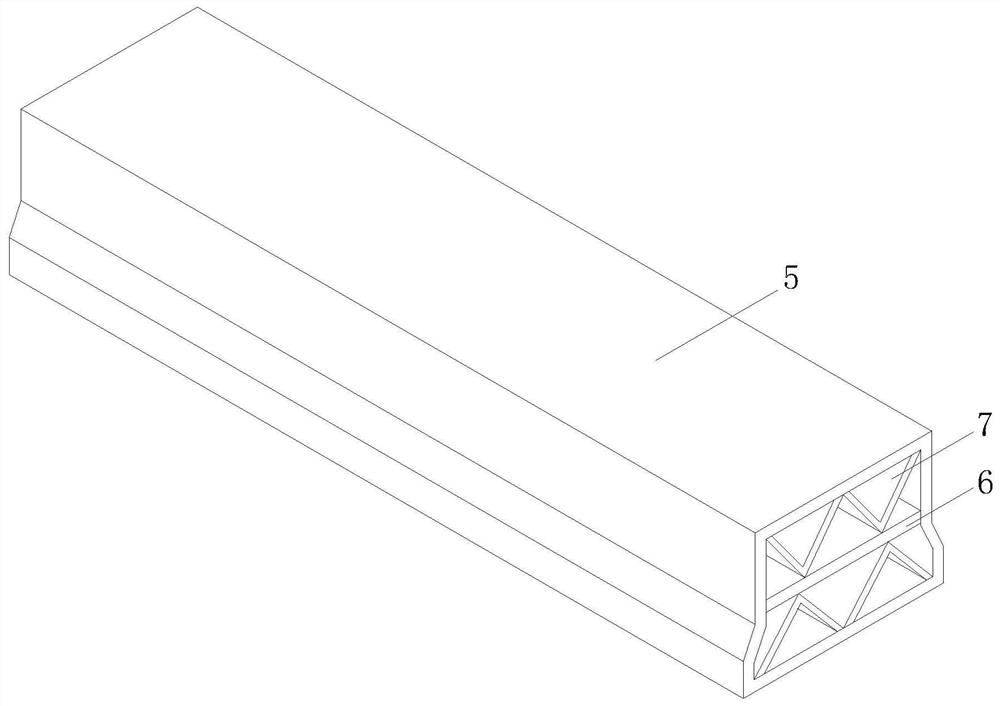

[0026] Example: as Figure 1-6 As shown in the figure, an OKKEN profile for high-voltage switchgear and its heat treatment process of the present invention includes a profile body, and the profile body consists of an OKKEN profile body 1, several first round holes 2, several square holes 3, several second round holes A hole 9 and a gap 4 are formed. The interior of the OKKEN profile body 1 is provided with a reinforcement component. The reinforcement component is composed of a reinforcement pipe 5, a reinforcement plate 6, two wave plates 7 and several sound-absorbing cottons 8.

[0027] Among them, several first round holes 2 and several square holes 3 are respectively opened at the top of the OKKEN profile body 1 for practice bikes, the distances between several first round holes 2 are the same, and the distances between several square holes 3 are the same , by setting the first round hole 2 and the square hole 3, the OKKEN profile body 1 can be easily connected with the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com