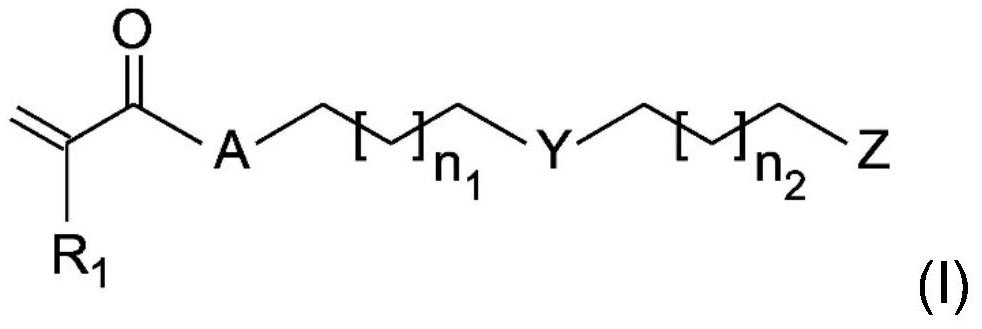

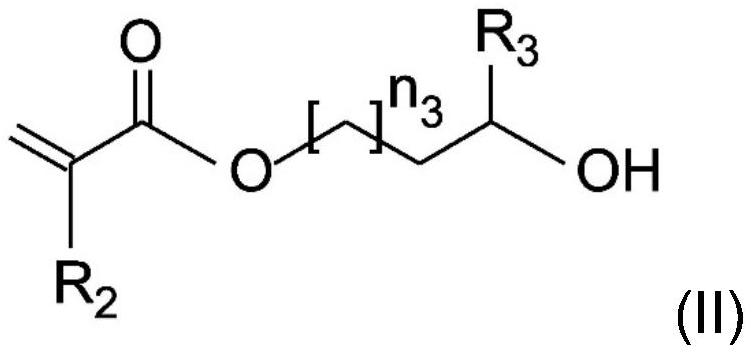

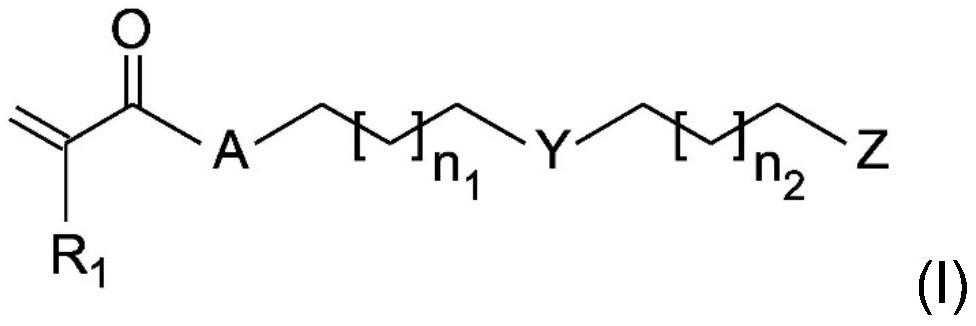

Anti-fog material and manufacturing method thereof

A preparation method and composition technology, which is applied in the field of anti-fog materials and its manufacture, and can solve the problems of poor physical properties of anti-fog materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation procedure, compounds and conditions of Example 1 of the present disclosure are as follows. Using a 30ml sample bottle, put a stir bar, and add 1.4g of the ionic compound [2-(methacryloyloxy)ethyl]dimethyl -(3-sulfopropyl)ammonium hydroxide ([2-(Methacryloyloxy)ethyl]dimethyl-(3-sulfopropyl)ammonium hydroxide, CAS3637-26-1), 6.6g surface active compound (2-Hydroxyethyl methacrylate, CAS. 868-77-9) stir at room temperature for 3 hours and mix well, put into ultrasonic shaker for 5 minutes to remove air bubbles, then add 2.0g hard compound pentaerythritol tetraacrylate (Pentaerythritol tetraacrylate, CAS 4986-89-4) and mix well After that, put it into an ultrasonic shaker for 5 minutes to remove air bubbles. The above solution was coated with a 25 μm wire rod on a 125 μm PET film, placed in an oven at 90° C. for heating for 1 minute and taken out.

Embodiment 2

[0045] The preparation procedure, each compound, and conditions of Example 2 of the present disclosure are as follows. Using a 30ml sample bottle, put a stir bar, and add 2.4g of the ionic compound [2-(methacryloyloxy)ethyl]dimethyl -(3-sulfopropyl)ammonium hydroxide ([2-(Methacryloyloxy)ethyl]dimethyl-(3-sulfopropyl)ammonium hydroxide, CAS3637-26-1), 4.9g surface active compound (2-Hydroxyethyl methacrylate, CAS. 868-77-9) stir at room temperature for 3 hours and mix well, put into ultrasonic shaker for 5 minutes to remove air bubbles, then add 2.7g hard compound pentaerythritol tetraacrylate (Pentaerythritol tetraacrylate, CAS 4986-89-4) and mix well After that, put it into an ultrasonic shaker for 5 minutes to remove air bubbles. The above solution was coated with a 25 μm wire rod on a 125 μm PET film, placed in an oven at 90° C. for heating for 1 minute and taken out.

Embodiment 3

[0047] The preparation procedure, each compound, and conditions of Example 3 of the present disclosure are as follows. Using a 30ml sample bottle, put a stir bar, and add 1.4g of the ionic compound ([3-(Methacryloylamino)propyl](3-sulfonatopropyl)dimethylaminium, CAS.5205-95-8) and 6.6g of surface active compound (2-Hydroxyethylmethacrylate, CAS.868-77-9) were stirred at room temperature for 3 hours and mixed well, put into an ultrasonic shaker for 5 minutes to remove air bubbles, and then added 2.0 g The hard compound Pentaerythritol tetraacrylate (Pentaerythritoltetraacrylate, CAS 4986-89-4) was mixed uniformly, and then placed in an ultrasonic shaker for 5 minutes to remove air bubbles. The above solution was coated with a 25 μm wire rod on a 125 μm PET film, placed in an oven at 90° C. for heating for 1 minute and taken out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com