Equipment and method for measuring heat value of material through oxygen consumption method

A technology of material and calorific value, which is applied in the field of measuring the calorific value of materials through the oxygen consumption method, can solve the problems of heat loss, inaccurate calculation of heat, and influence on measurement accuracy, etc., to achieve accurate results, convenient automatic measurement, and accurate measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

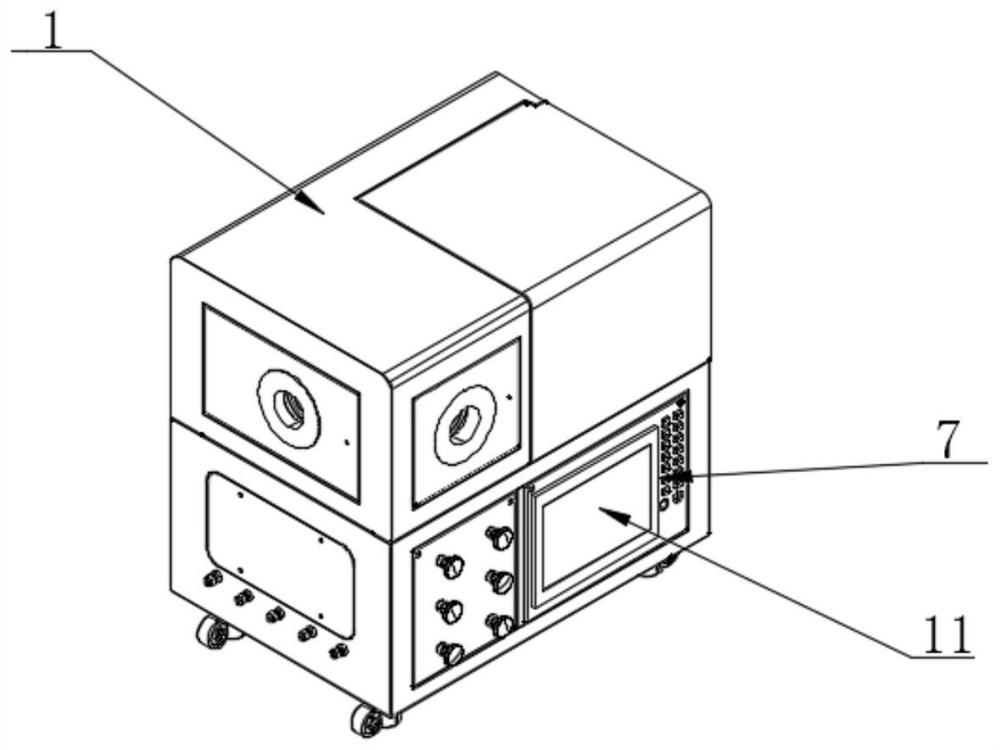

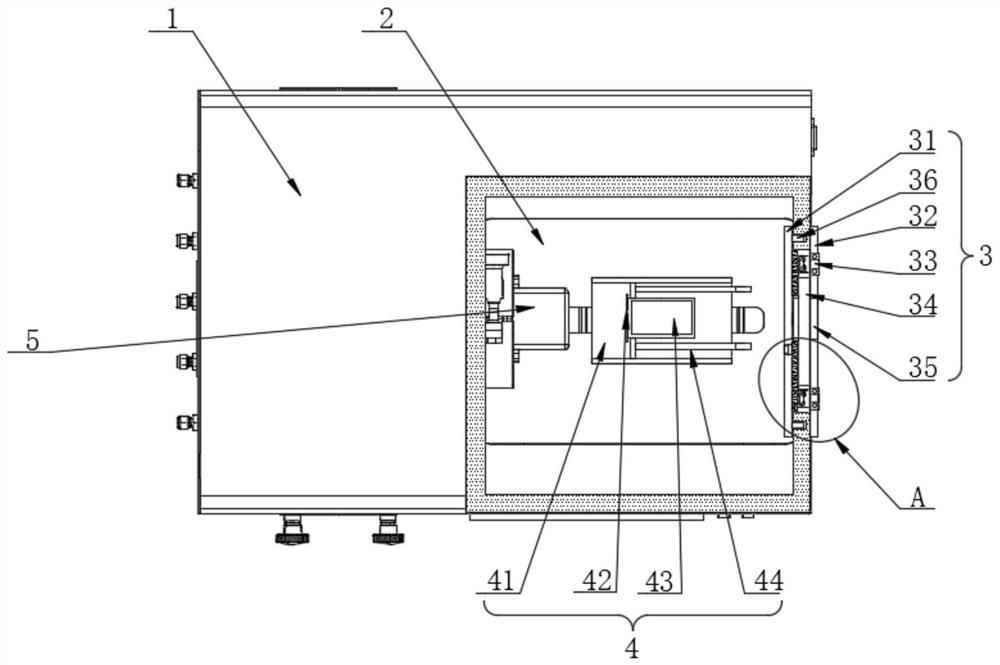

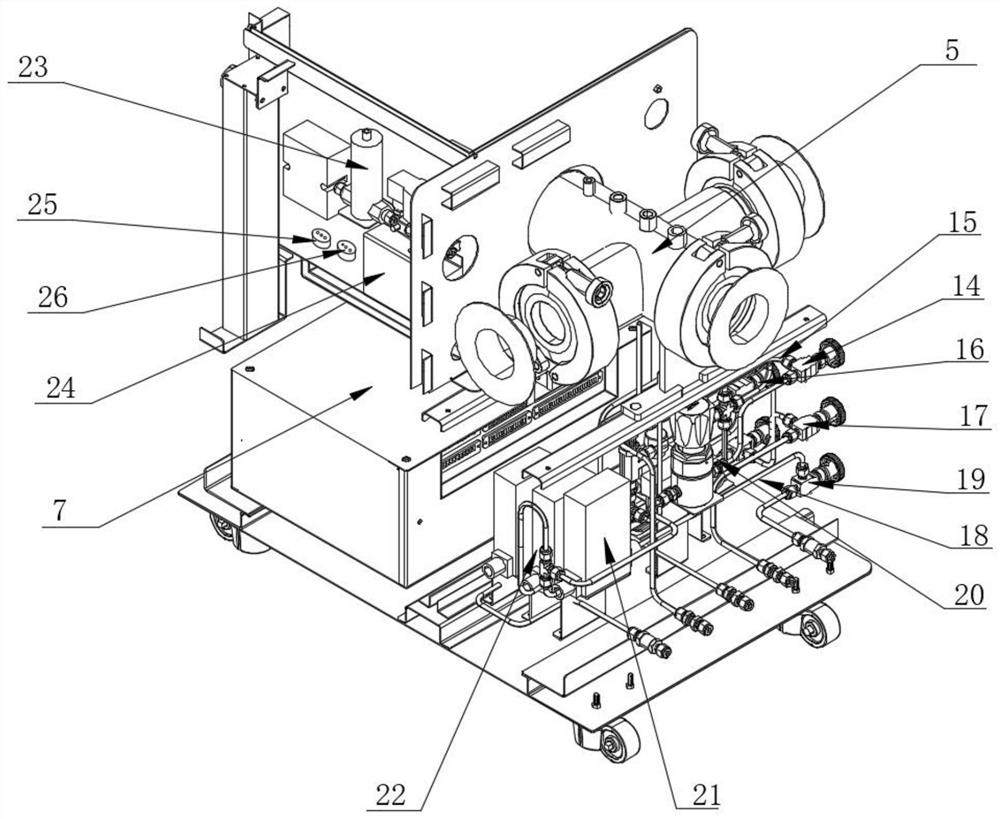

[0048] Reference manual attached Figure 1-2 , this embodiment provides a device for measuring the calorific value of materials by the oxygen consumption method, the tester shell 1 and the main control device 7 arranged in the tester shell 1, and the tester shell 1 is provided with a test cavity 2. One end of the test cavity 2 is provided with a push window assembly 3 and a sealing module 8, which are used to maintain the sealed state of the test cavity 2. The interior of the tester shell 1 can be additionally equipped with an overpressure gas leakage protection module according to the needs of the actual test work. , over-temperature alarm device and automatic measurement equipment for ignition point, etc., this application only mentions the specific structure of the inflatable and deflated module that realizes this technical solution as the main;

[0049] an air-filling module, the air outlet of the air-filling module is communicated with the test cavity 2, and is used to fill...

Embodiment 2

[0057] Reference manual attached Figure 3-5 , on the basis of the first embodiment, the push window assembly 3 includes an inner window 31 and an outer sealing plate 32 respectively disposed on the inner and outer sides of the feeding end of the test cavity 2, and the outer sealing plate 32 faces the inner window 31. A linear motor 33 is symmetrically arranged on one side, and the linear motor 33 is slidably fitted with the base 34 , the sealing module 8 is arranged on the base 34 , and the inner window 31 is symmetrically arranged and tested on the side facing the outer sealing plate 32 . The sealing insert 36 to which the cavity 2 is inserted, the outer sealing plate 32 is provided with a feeding port 35 in the middle, and the feeding end of the test cavity 2 is provided with a limit frame whose width is adapted to the feeding port 35 9. The base 34 is arranged between the limit frame 9 and the outer sealing plate 32 , and the feeding end of the test cavity 2 is located at ...

Embodiment 3

[0064] This embodiment provides a method for measuring the calorific value of a material by an oxygen consumption method according to any of the above-mentioned equipment, which specifically includes the following steps:

[0065] Step 1, weigh a certain quality of dry material and put it on the heating module 4, and drive the feeding end of the test cavity 2 to close and maintain a sealed state through the window push assembly 3 and the sealing module 8;

[0066] In step 2, the test cavity 2 is filled with pure air by the air charging module to reach the rated pressure value, and the oxygen concentration, temperature and pressure value in the test cavity 2 before combustion are recorded, and the values are accurate to 1%;

[0067] In step 3, the heating module 4 heats the material to 600°C, and after holding for 30 minutes, the oxygen concentration, temperature and pressure in the test chamber 2 after combustion are measured, and the values are accurate to 1%;

[0068] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com