Heat dissipation plate of parallel multi-fluid-channel flow equalizing structure and optical fiber laser

A technology of fiber lasers and fluid channels, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of medium leakage, failure to meet demand, occupying space of fiber lasers, etc., and achieve uniform temperature distribution, stable and reliable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

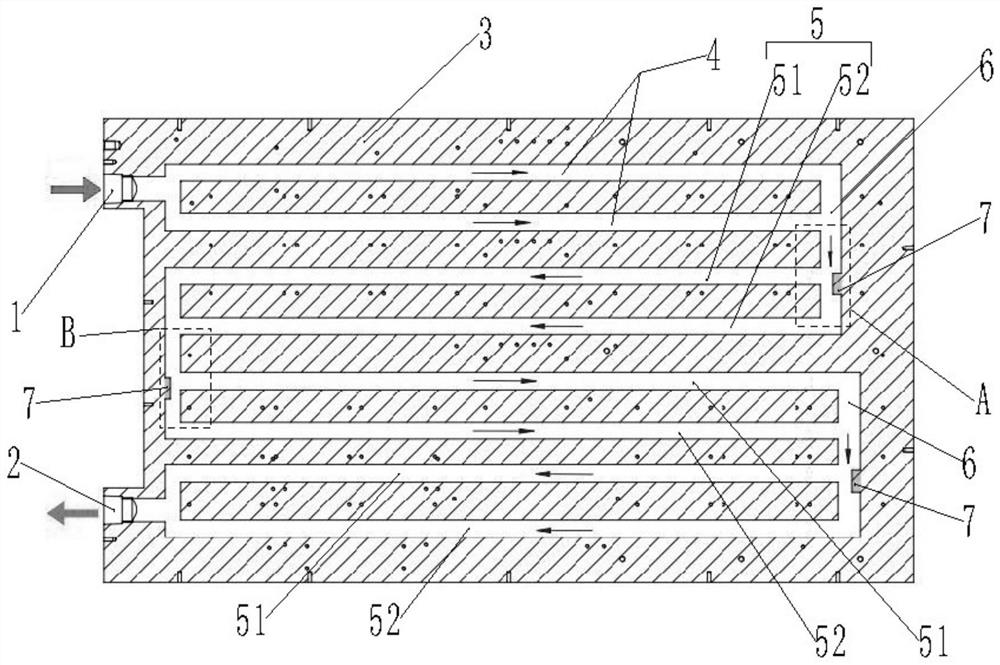

[0030] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary, only used to explain the present invention, and should not be construed as a limitation of the present invention. On the contrary, embodiments of the present invention include all changes, modifications and equivalents falling within the spirit and scope of the appended claims.

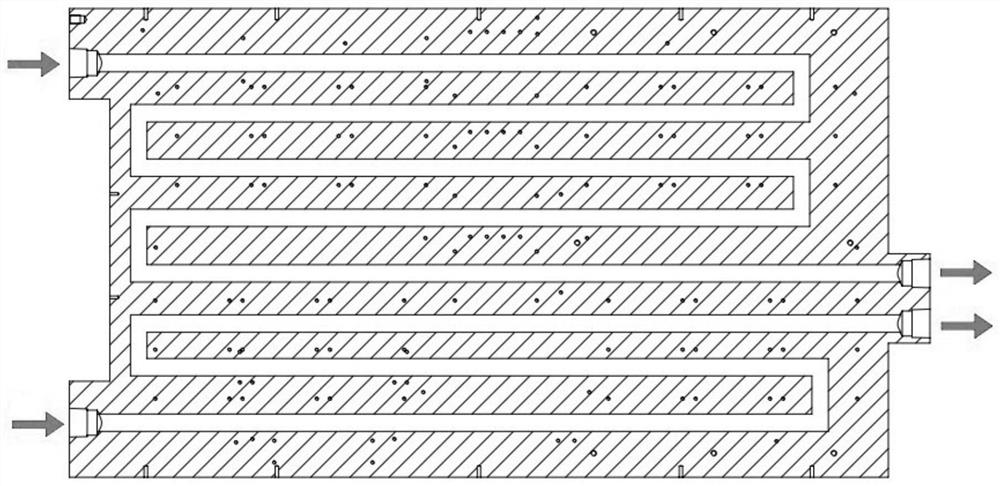

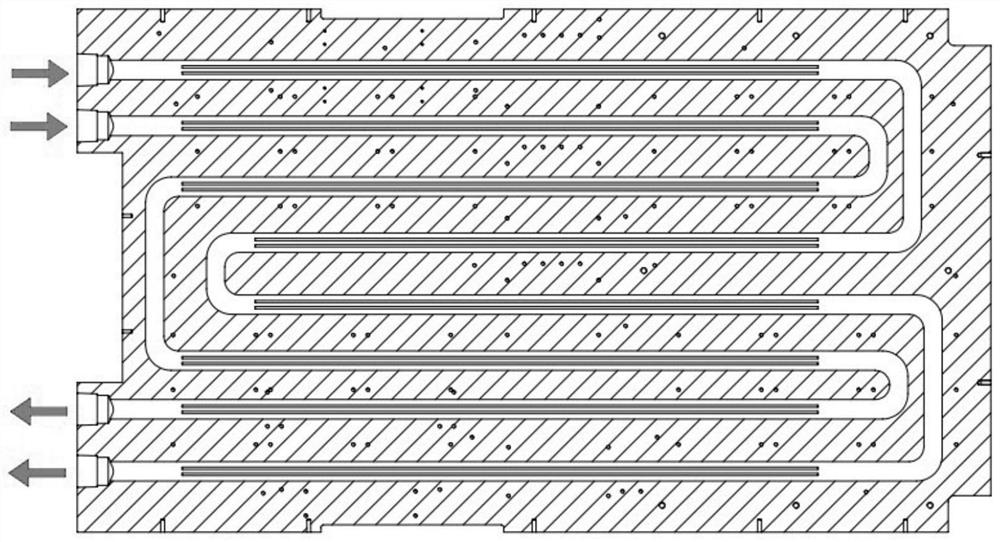

[0031] image 3 It is a schematic diagram of a heat dissipation plate with a parallel multi-fluid channel flow-equalizing structure provided by an embodiment of the present invention.

[0032] see image 3 , This embodiment provides a heat dissipation plate with a parallel multi-fluid channel flow-equalizing structure. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com