Non-metal internal inflow sludge filtration integrated device

A sludge filtration and non-metallic technology, which is applied in the direction of filtration separation, sludge treatment, mobile filter element filter, etc., can solve the problem of easy clogging of filter holes by hair fibers, so as to improve friendliness, improve efficiency and reduce clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

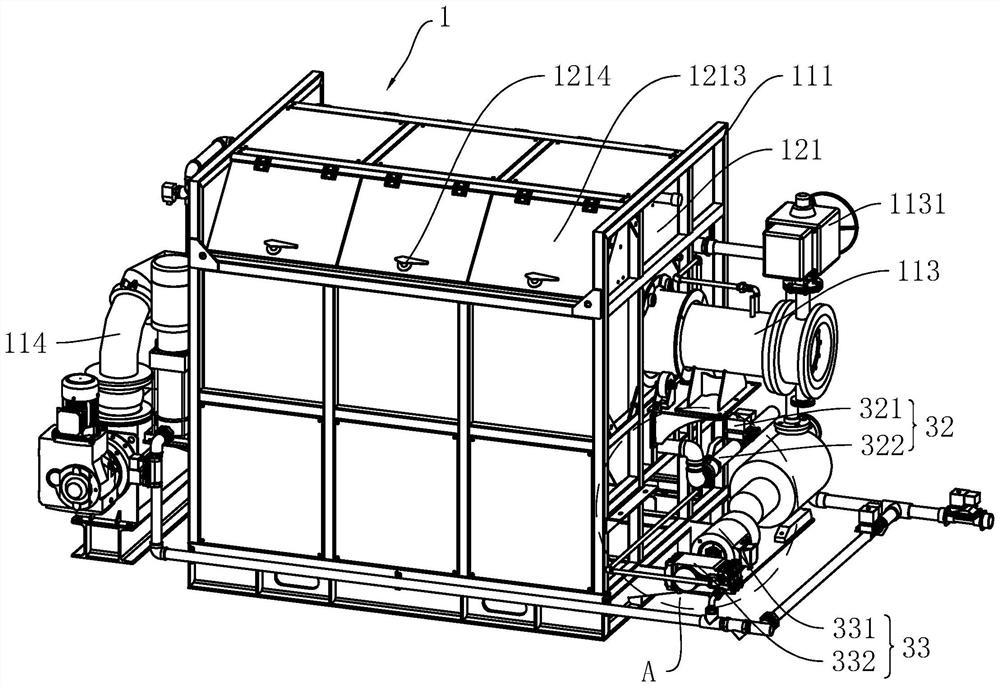

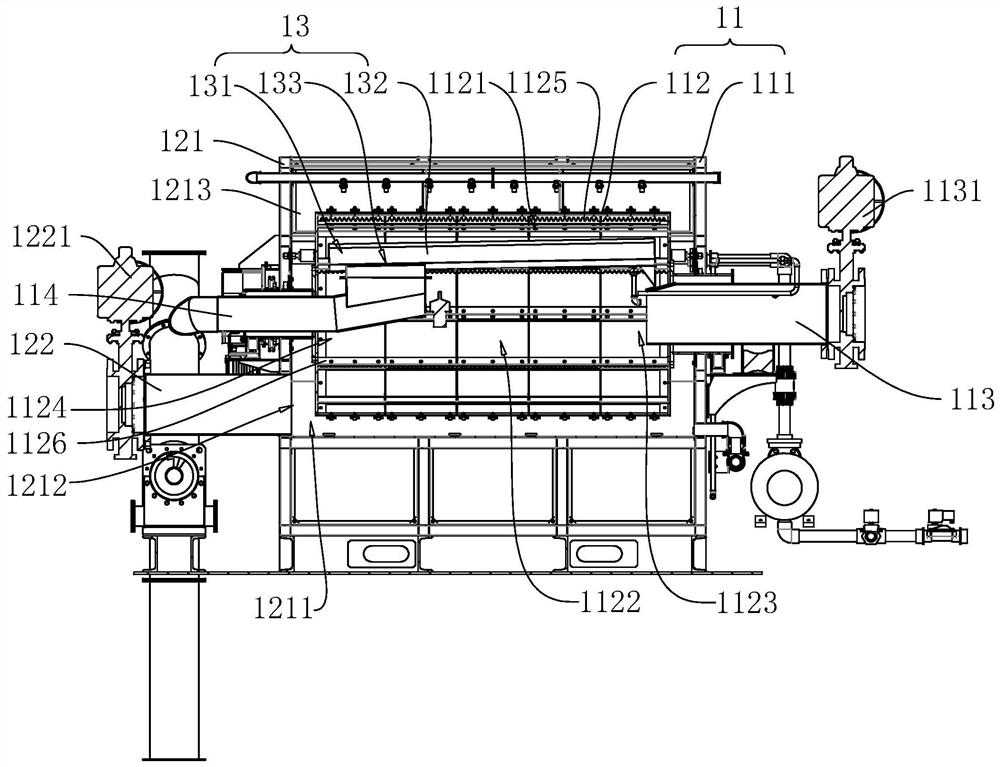

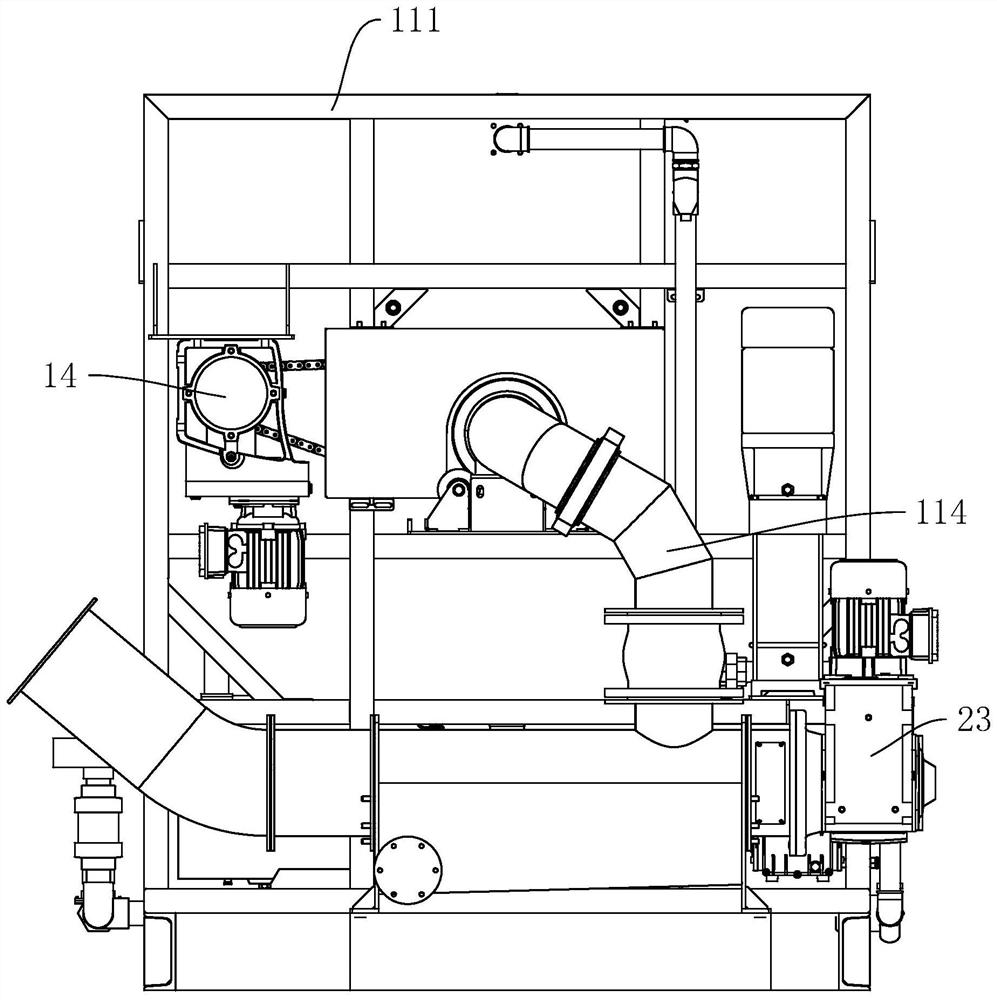

[0041] Attached to the following Figure 1-5 This application will be described in further detail.

[0042] The embodiment of the present application discloses a non-metal internal inflow sludge filtering integrated device.

[0043] refer to figure 1 , the non-metal internal inflow sludge filtration integrated device includes a sludge filter mechanism 1 for sludge filtration, a screen slag pressing mechanism 2 for squeezing and dewatering the filter residue, and a sludge filter mechanism 1 for cleaning. The cleaning mechanism 3 and the control mechanism 4 for controlling each part.

[0044] refer to figure 1 and figure 2 The sludge filtering mechanism 1 includes a grid plate assembly 11, a frame assembly 12, an inner slag groove assembly 13 and a driving member 14. The inner slag groove assembly 13 is installed in the grid plate assembly 11, and the driving member 14 drives the grid plate assembly 11 to rotate.

[0045] refer to figure 2 , the grid plate assembly 11 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com