Production and recovery system and production and recovery process for producing light oil from waste tires

A waste tire and recycling system technology, applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of old equipment, easy to generate large dust, easy to adhere to large dust, etc., to reduce the burden, improve cleanliness, Not easy to generate dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

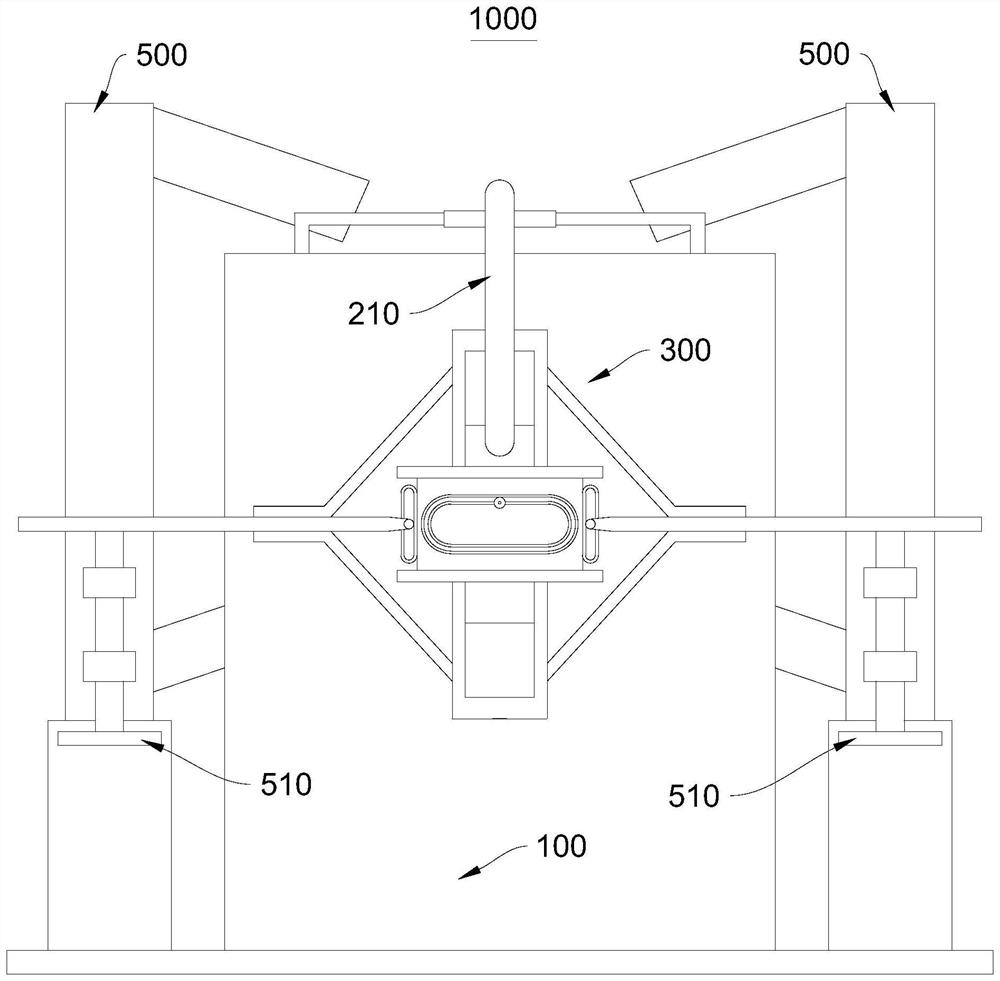

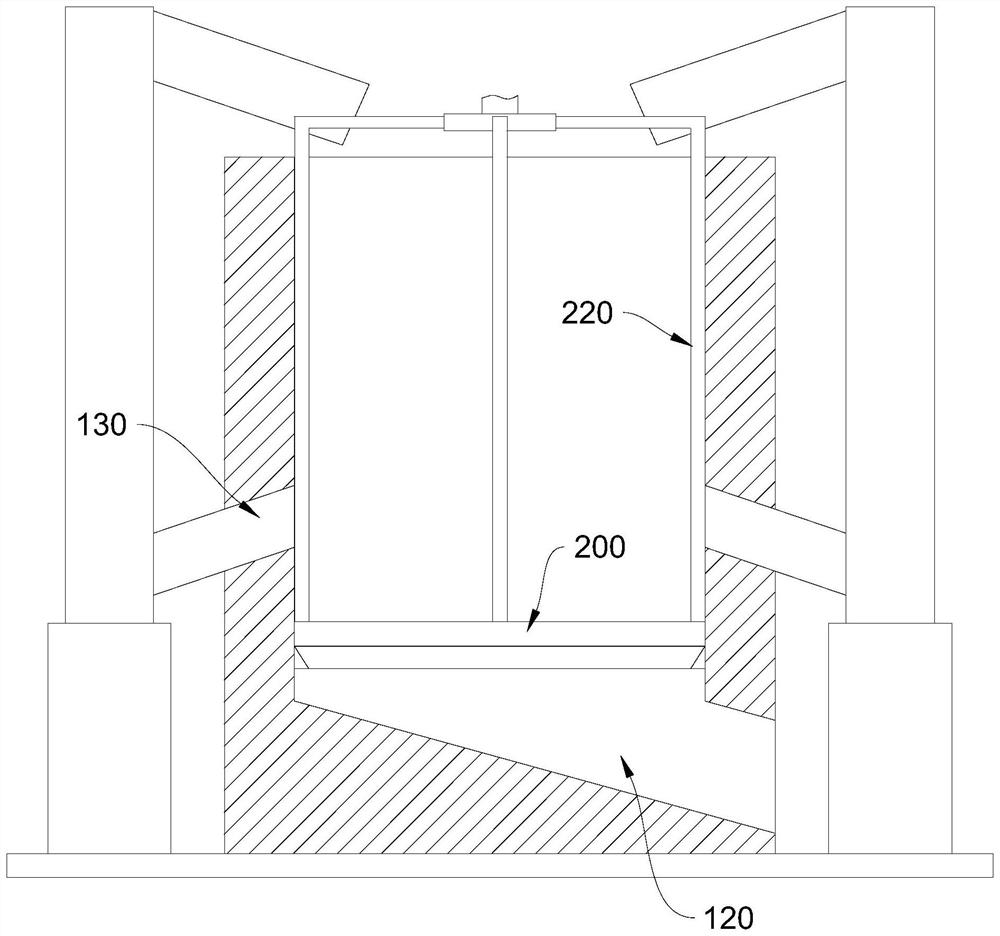

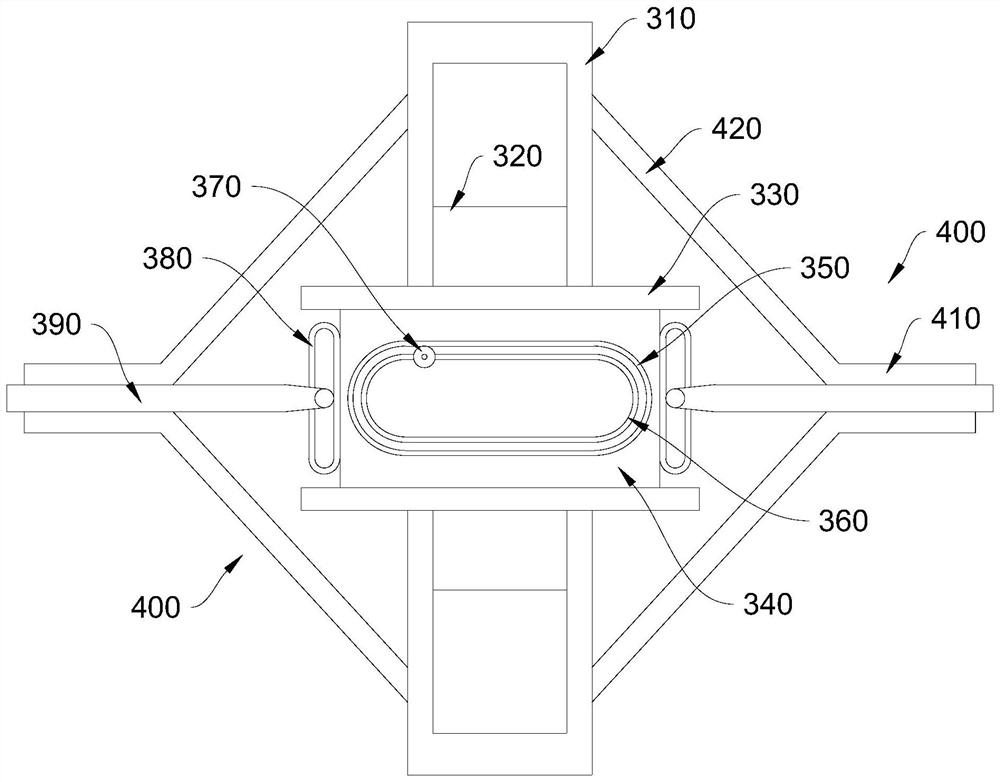

[0050] Please refer to figure 1 and figure 2 , This embodiment provides a production recovery system 1000 for producing light oil from waste tires. The production recovery system 1000 includes: a tank body 100 , a mesh plate 200 , a lifting mechanism 300 and a screw conveying mechanism 500 .

[0051] The tank body 100 has an inner cavity 110, and the mesh plate 200 is slidably fitted in the tank body 100 for receiving scrap tires. The screen plate 200 is connected with the lifting mechanism 300 for lifting and lowering the screen plate 200 intermittently.

[0052] The bottom of the inner cavity 110 is provided with a dust discharge port 120 for discharging dust. The two sides of the tank body 100 are also provided with discharge pipes 130. The discharge pipes 130 are arranged close to the bottom of the inner cavity 110 and are spaced from the bottom of the inner cavity 110. The outer ends of the discharge pipes 130 face the bottom of the tank body 100. Extended settings. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com