Rocker soot cleaning plate cooler

A soot cleaning board and cooler technology, applied in the field of high temperature flue gas cooling, rocker soot cleaning plate cooler, can solve the problems of poor heat exchange effect, inconvenient maintenance and replacement, damage to dust collection equipment, etc., and achieve convenient maintenance and replacement , good heat exchange effect, good dust cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

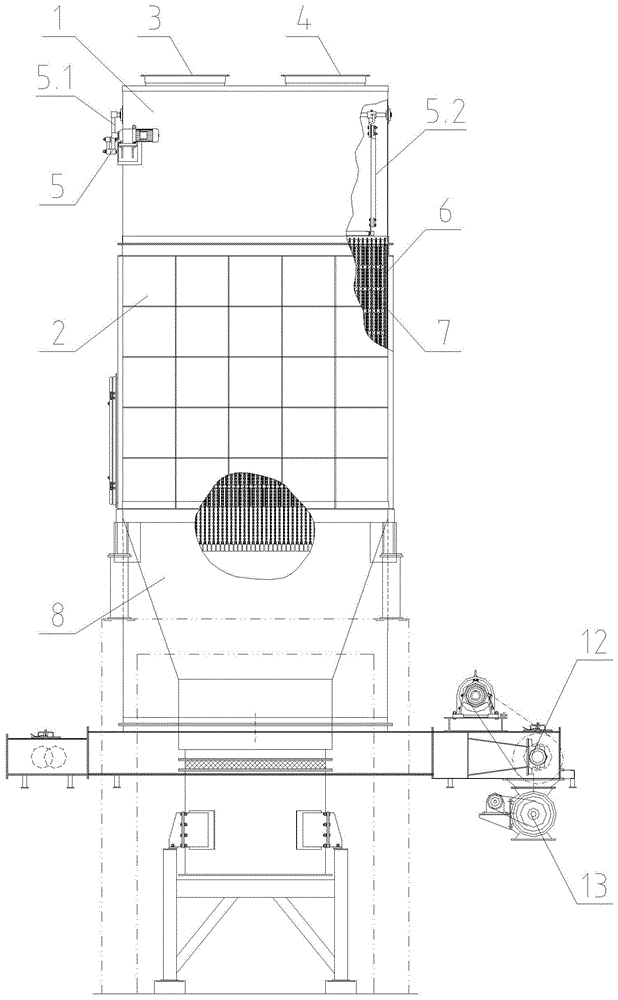

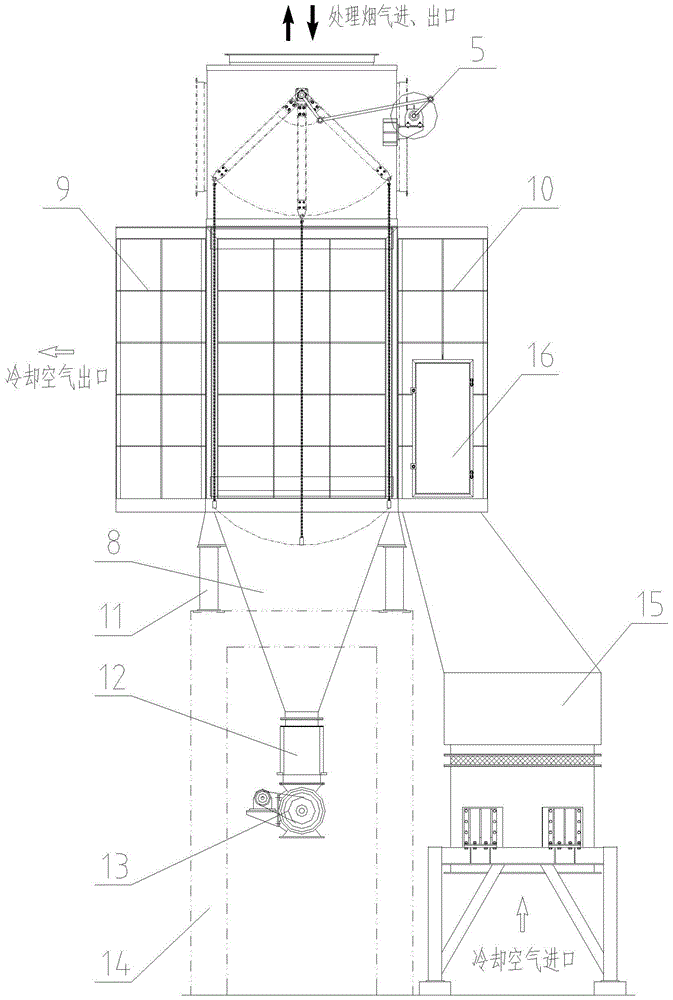

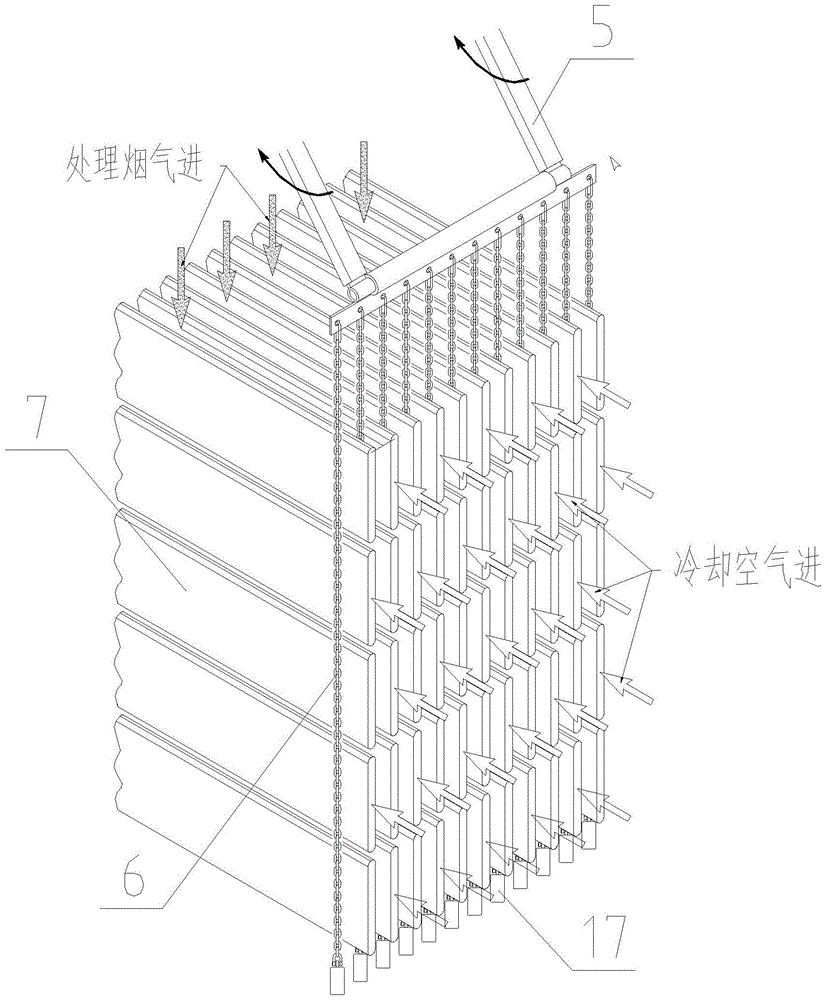

[0062] see Figure 1~Figure 10 , a kind of rocker soot-cleaning plate type cooler of the present invention, it comprises base frame 14, and described base frame 14 is provided with support frame 11, and described support frame 11 is provided with upper box body 1 and lower box body successively from top to bottom. The box body 2, the front and rear sides of the lower box body 2 are respectively provided with a cooling air discharge box 9 and a cooling air entry box 10, the cooling air entry box 10 is provided with an inspection door 16, and the cooling air entry box 10 is below A cooling air inlet device 15 is provided, an ash hopper 8 is provided at the bottom of the lower box 2, a buried scraper 12 is provided at the bottom of the ash hopper 8, and an ash discharge valve 13 is provided at the outer end of the buried scraper 12 ;

[0063] A partition 18 is longitudinally arranged in the middle of the upper box 1 and the lower box 2, and the partition 18 divides the upper box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com