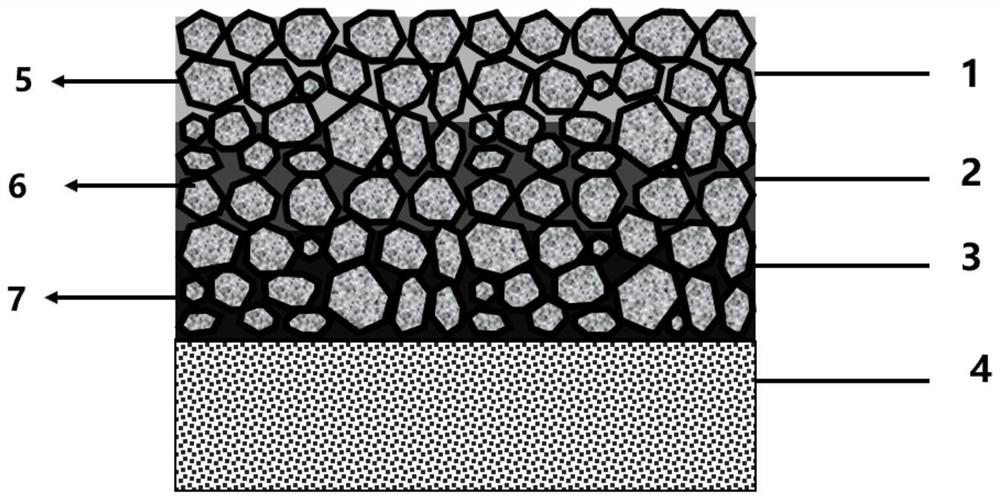

Self-supplementing type salt storage and ice and snow melting asphalt concrete pavement structure based on concentration gradient

A technology of asphalt concrete and concentration gradient, which is applied to coagulating pavement, roads, roads and other directions paved on site, which can solve the problems of short time for road surface melting ice and snow, slow-release salt storage filler interlocking, filler waste, etc., to achieve Improve the service life, increase the effective life, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

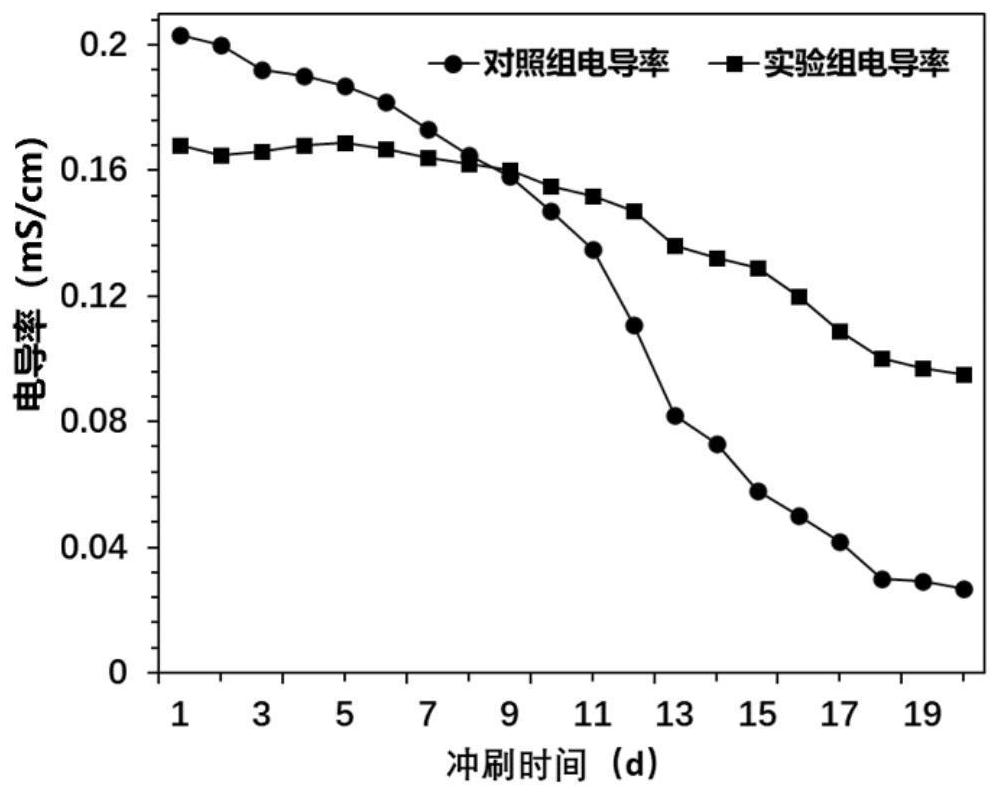

Examples

preparation example Construction

[0047] Wherein, the preparation method of the asphalt mixture containing the mass fraction of 9% high-purity slow-release salt storage ice-melting ice-snow filler, includes the following steps:

[0048] Step 1. Heating: Heat the high-purity slow-release salt-storage melting ice and snow filler in an oven with a temperature of 170°C.

[0049] Step 2. Blending: Add the heated high-purity slow-release storage salt melting ice and snow filler to the asphalt mixture mixing furnace at a mixing ratio of 9% by mass, and mix with the asphalt mixture evenly, such as stirring for 75s, etc.

[0050] Step 3. Pressing: Press the asphalt mixture mixed with the high-purity slow-release salt-storing, ice-melting and snow-melting filler to form a rutting plate test piece.

[0051] 3. Lay the middle surface layer, and lay the asphalt mixture containing 7% high-purity slow-release salt storage ice-melting ice and snow filler on the lower layer and compact it.

[0052] The preparation method of a...

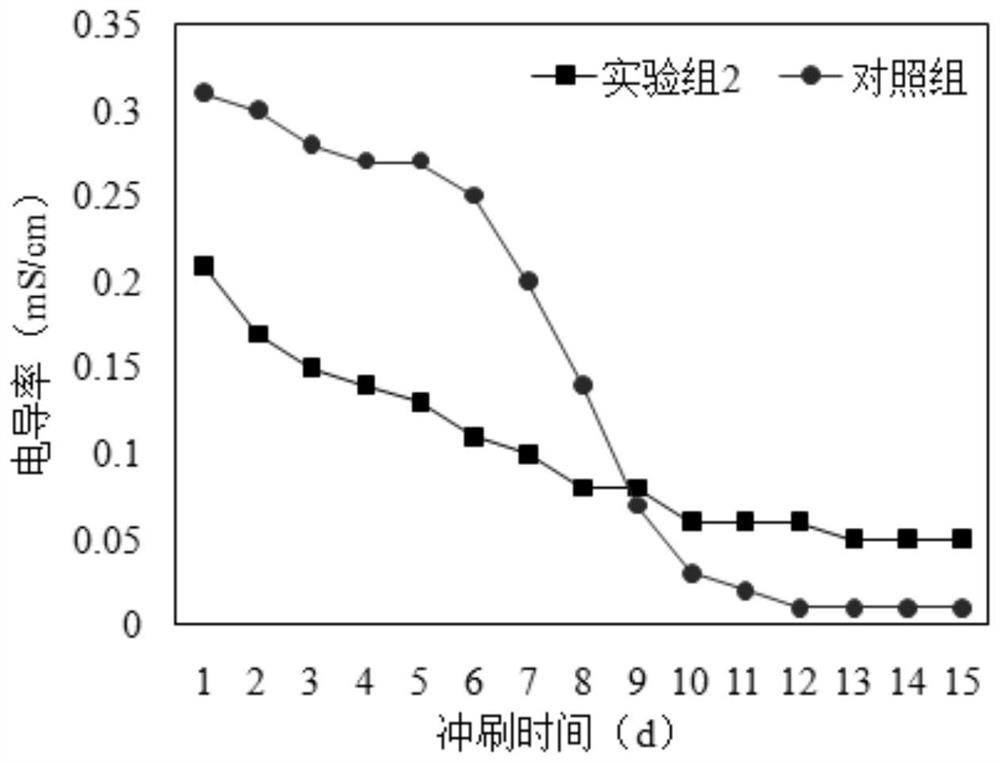

Embodiment 2

[0055] Example 2 of the present application (referred to as experimental group 2)

[0056] 1. Lay the roadbed and compact it.

[0057] 2. Lay the lower layer, and lay the SMA asphalt mixture containing 10% high-purity slow-release salt storage ice-melting ice and snow filler on the roadbed and compact it.

[0058] Wherein, the preparation method of the SMA asphalt mixture containing the mass fraction of 10% high-purity slow-release salt storage ice-melting ice and snow filler, includes the following steps:

[0059] Step 1. Heating: Heat the high-purity slow-release salt-storage melting ice and snow filler in an oven with a temperature of 170°C.

[0060] Step 2. Blending: Add the heated high-purity slow-release salt storage and melting ice and snow filler to the SMA asphalt mixture mixing furnace according to the mixing ratio of 10% by mass, and stir the asphalt mixture evenly, such as stirring for 75s, etc. .

[0061] Step 3. Pressing: Press the SMA asphalt mixture mixed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com