Pressure testing machine

A technology of pressure testing and driving motors, applied in the direction of applying stable tension/pressure to test material strength, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] refer to Figure 1-6 , a pressure testing machine, comprising a base 1, the upper end of the base 1 is provided with a plurality of support rods 3, the upper ends of the plurality of support rods 3 are jointly sleeved with a top plate 4, the top plate 4 is fixedly connected with the plurality of support rods 3, and the top plate The lower end of 4 is provided with a hydraulic rod 5, the telescopic end of the hydraulic rod 5 is fixedly connected with a pressing block 6, the lower end of the base 1 is installed with a driving motor 7, and the end of the output shaft of the driving motor 7 penetrates the base 1 and is fixedly connected with a first rotating rod 11 , the drive motor 7 drives the first rotating rod 11 to rotate 90 degrees each time, and then it can be closed. The upper end of the first rotating rod 11 is fixedly connected with a disk 12, and the disk 12 is provided with a plurality of ports 13, each of which is The side of the opening 13 close to the axis of...

Embodiment 2

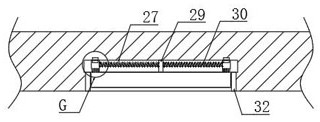

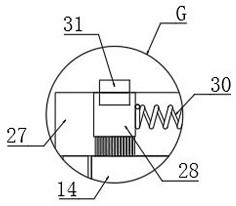

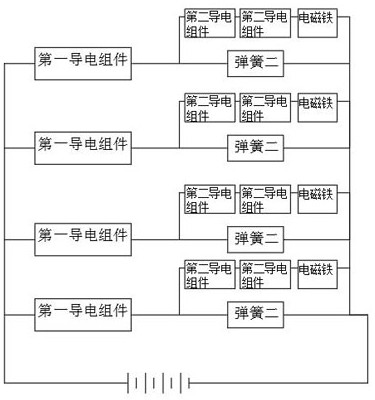

[0044] refer to Figure 7-11 The difference between this embodiment and Embodiment 1 is that the upper end of each telescopic groove 25 is provided with a brushing groove 27, and each brushing groove 27 is provided with a brushing assembly. The electromagnet 29 in the moving groove 27 is provided with two brushes 28 in the brushing groove 27. Each brush 28 is composed of a rectangular block and bristles. Each bristle is installed under the rectangular block. Made of iron material, the two brushes 28 are slidably connected to the inner wall of the brushing groove 27, and the adjacent surfaces of the two brushes 28 and the electromagnet 29 are elastically connected by springs 30. The upper end of each brush 28 is The inner top of the brushing groove 27 is provided with a conductive sheet 31 that cooperates with each other. The brushing groove 27 is communicated with the outside world through two blanking pipes 32. Each two matching conductive sheets 31 constitute a second conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com