Gas burning wall hanged furnace

A gas-fired wall-hung boiler and control system technology, used in lighting and heating equipment, fluid heaters, water heaters, etc., can solve the problems of poor heat dissipation, short life, affecting thermal efficiency, etc., to avoid pollution and simplify operating procedures. , Improve the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

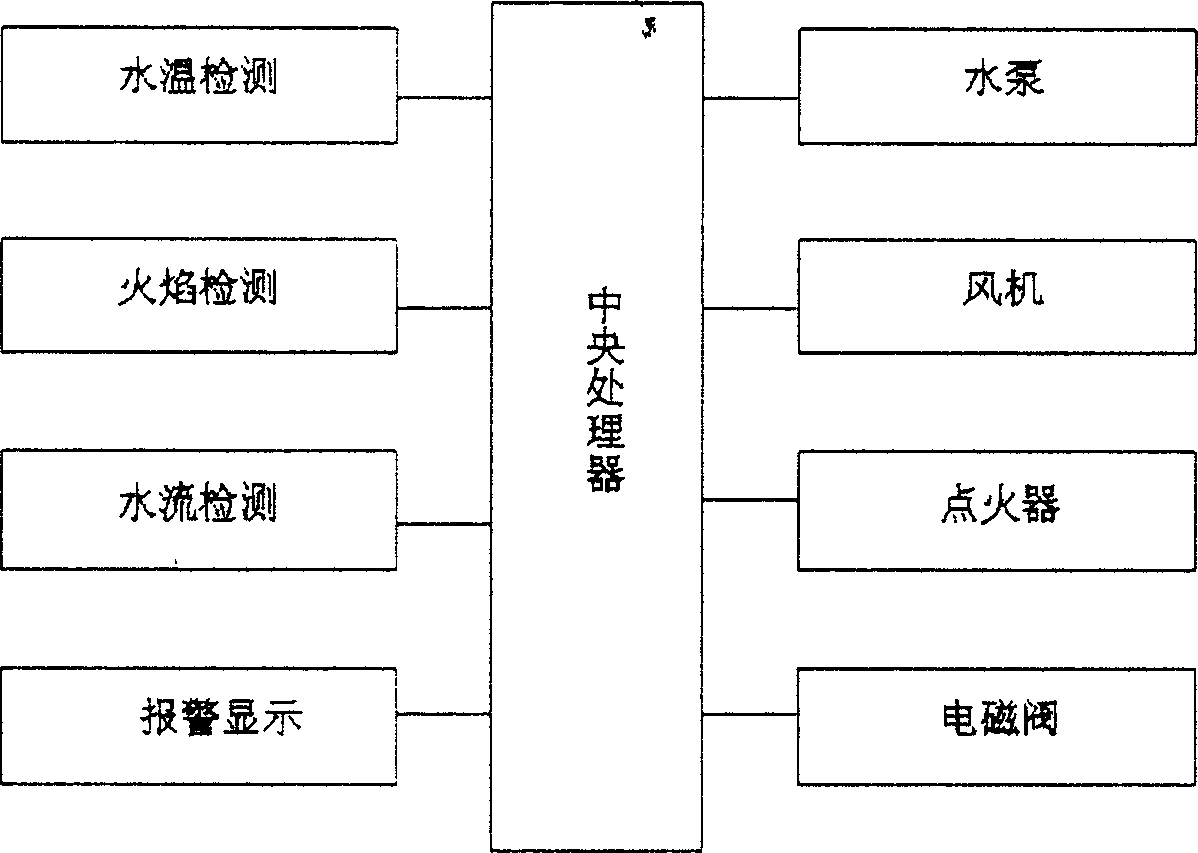

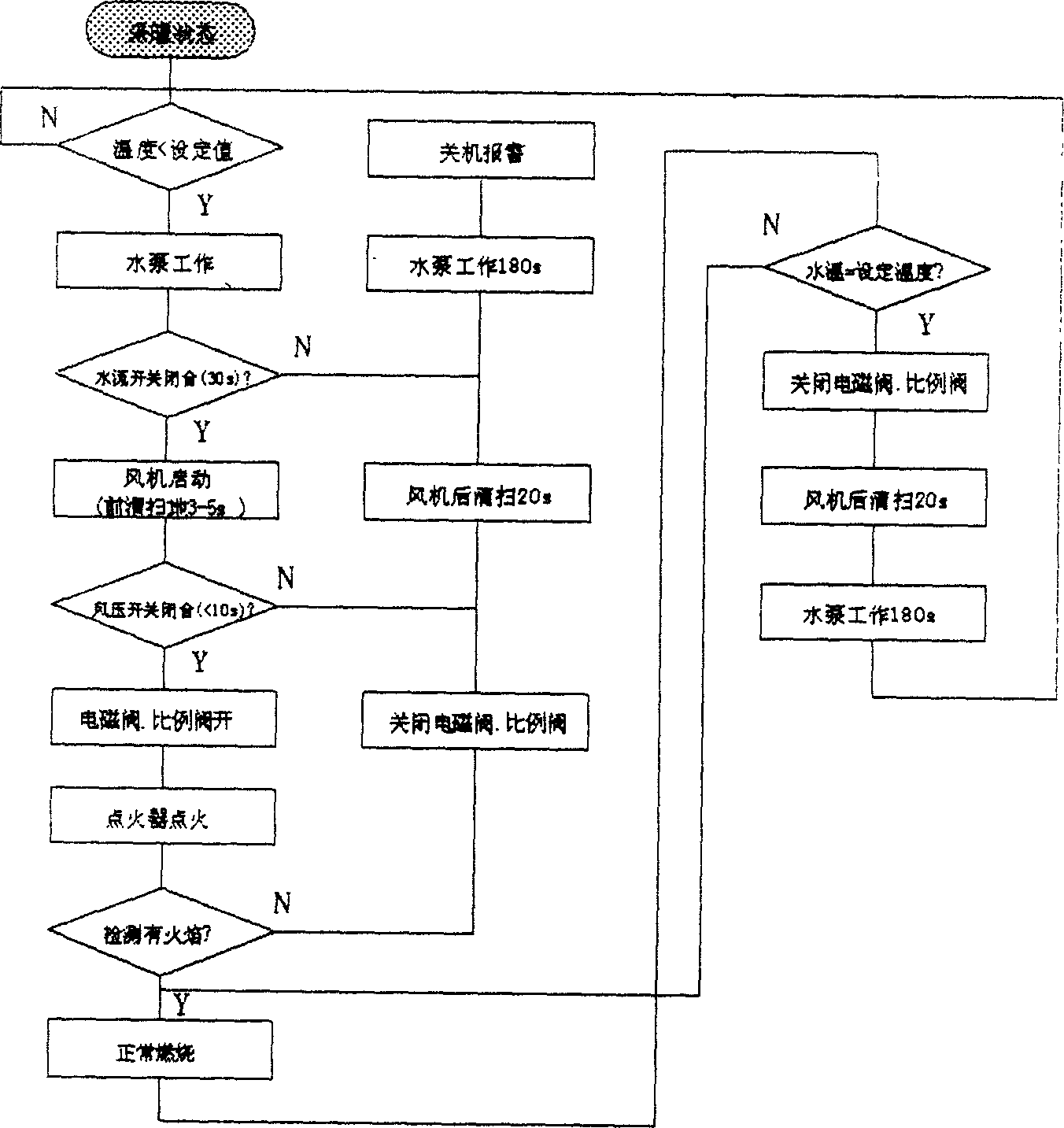

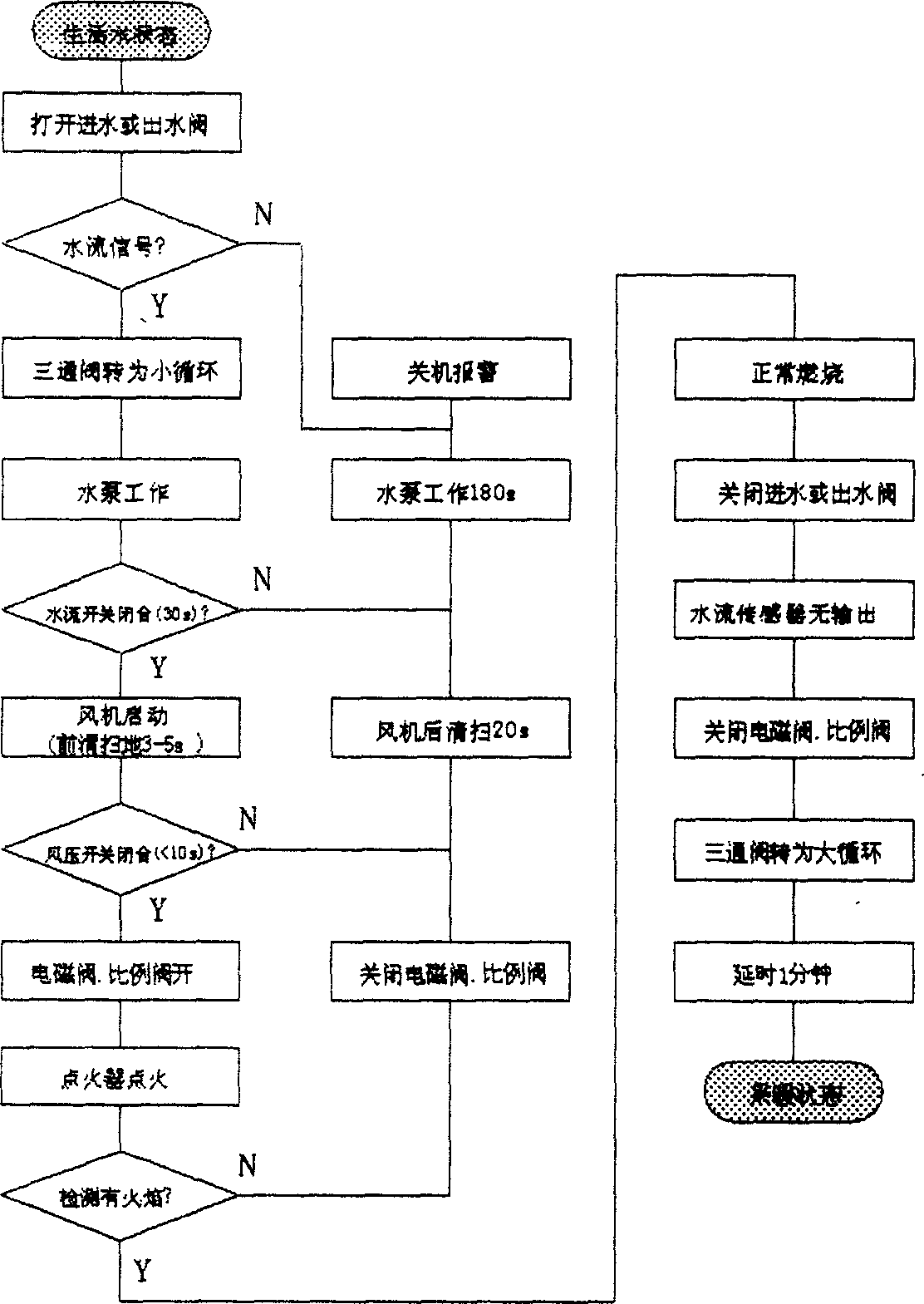

[0016] Below in conjunction with accompanying drawing, the utility model is further described:

[0017] The function of the gas wall-hung boiler is divided into two states: heating and domestic water supply. First, the heating working state is introduced. When the keyboard is set to heating, when the NTC probe senses that the water temperature is lower than the set temperature, the circulating water pump starts and the water flow switch closes. The microcomputer detects whether the flow reaches the starting value within 30S, and if it does not reach the starting value, it enters into the fault display and fault handling program. When the flow reaches the starting value within 30 seconds, enter the next step, start the fan, and clean up before combustion. The microcomputer detects that the air pressure switch is closed within 10S, and the closing time is ≥10S, the solenoid valve and the gas proportional valve are opened, and the ignition program is entered. At the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com