Cylindrical pot surface defect detection method and system, controller and industrial personal computer

A technology of defect detection and industrial computer, which is applied in the direction of optical testing of defects/defects, can solve the problems of image acquisition system influence, increase missed detection rate and false detection rate, and uneven lighting, so as to improve collection efficiency and inspection The output rate and the effect of overcoming uneven illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

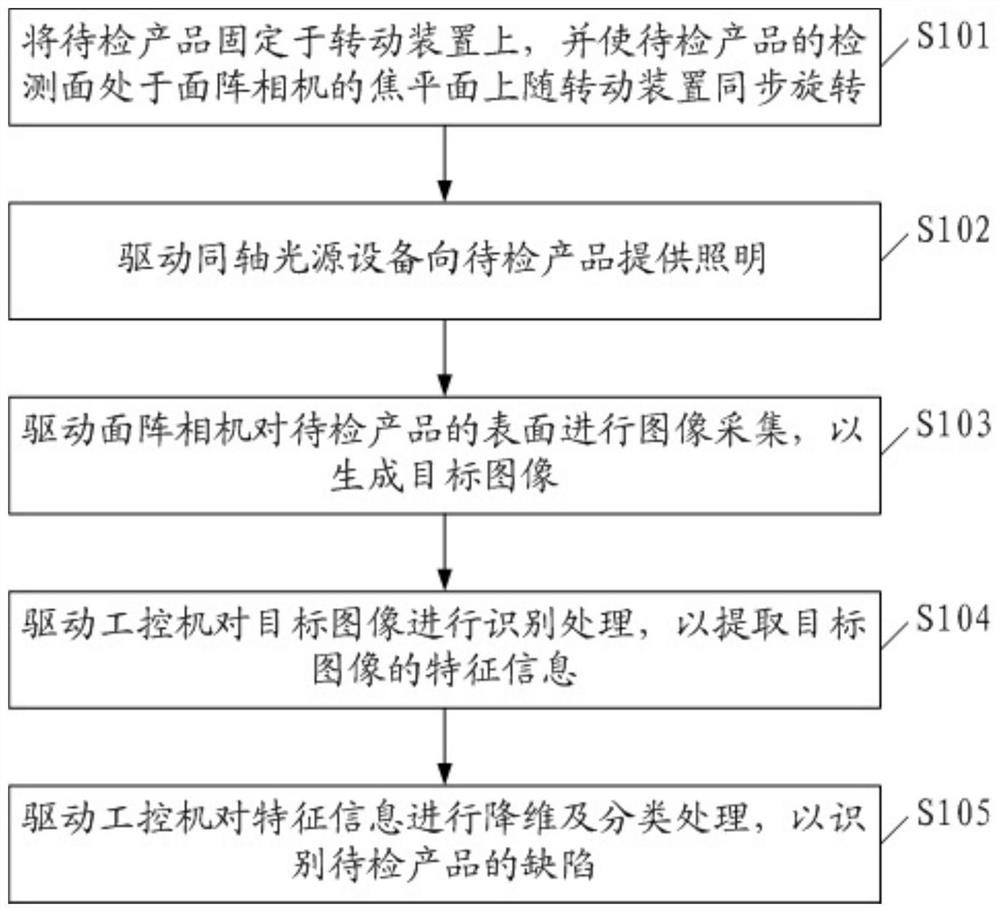

[0033] see figure 1 , figure 1 A flow chart of an embodiment of the method for detecting surface defects of a cylindrical pot of the present invention is shown, which includes:

[0034] S101, the product to be inspected is fixed on the rotating device, and the detection surface of the product to be inspected is placed on the focal plane of the area scan camera to rotate synchronously with the rotating device.

[0035] It should be noted that the product to be inspected in the present invention may be a metal cylindrical pot with high brightness reflection, but it is not limited thereto.

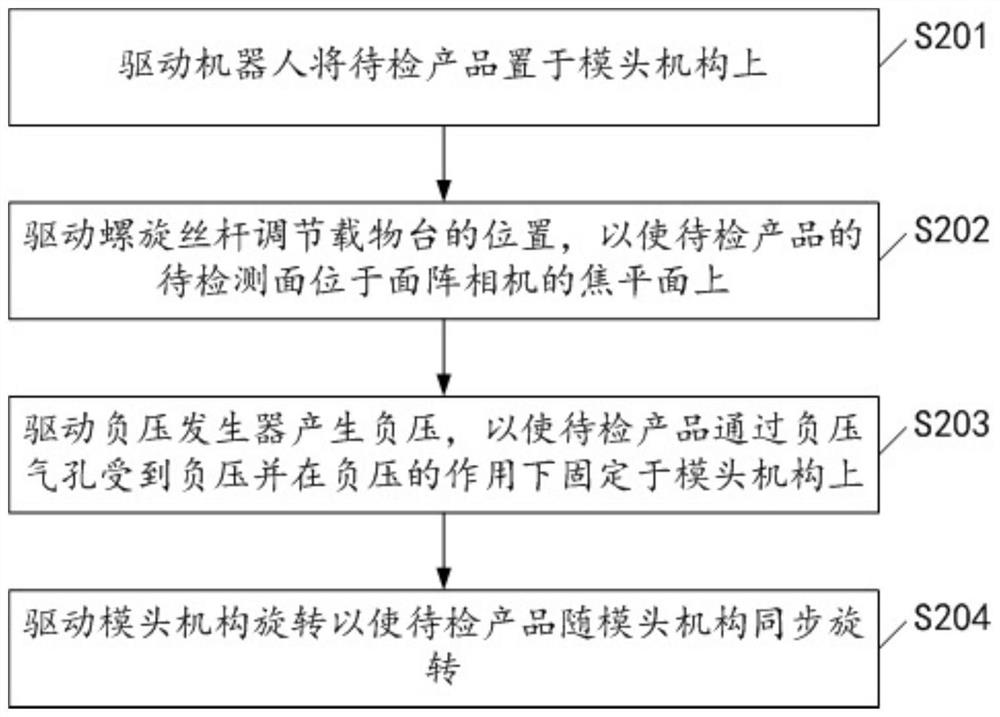

[0036] like Image 6 As shown, the cylindrical pot surface defect detection system includes an area scan camera, a coaxial light source device, a rotating device, a fixed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com