Fabric drapability detector and detection method

A drapability and detector technology, applied in the field of fabric drape detectors and detection, can solve the problems of reduced use performance, prone to excessive behavior, low contact comfort of detection components, etc., to extend service life, improve detection efficiency and The effect of using performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

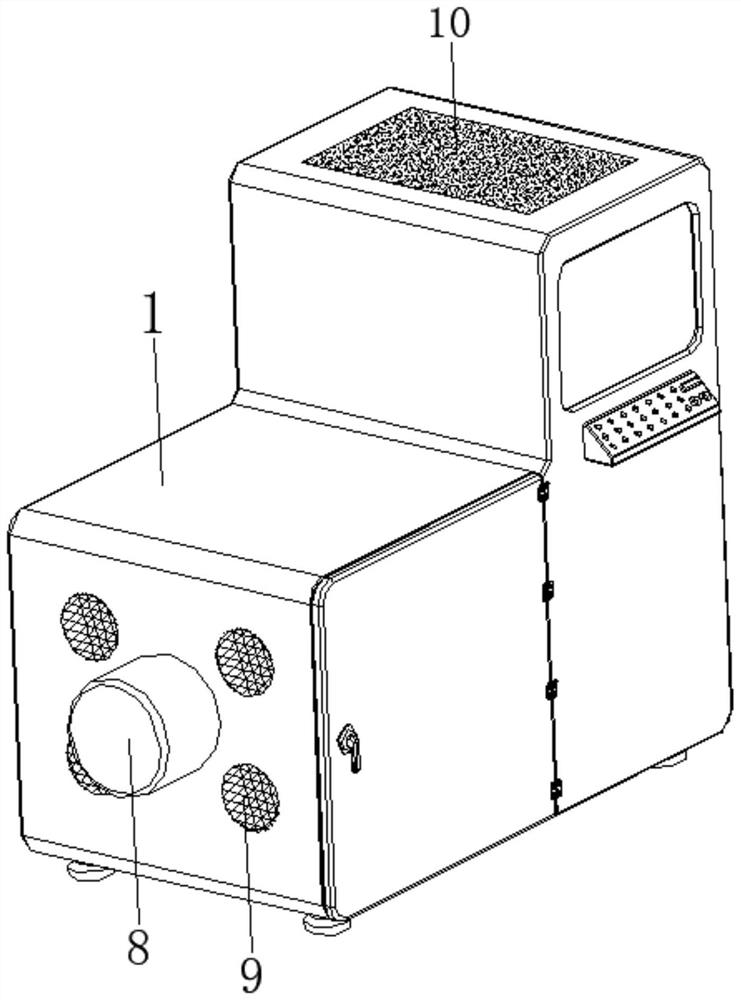

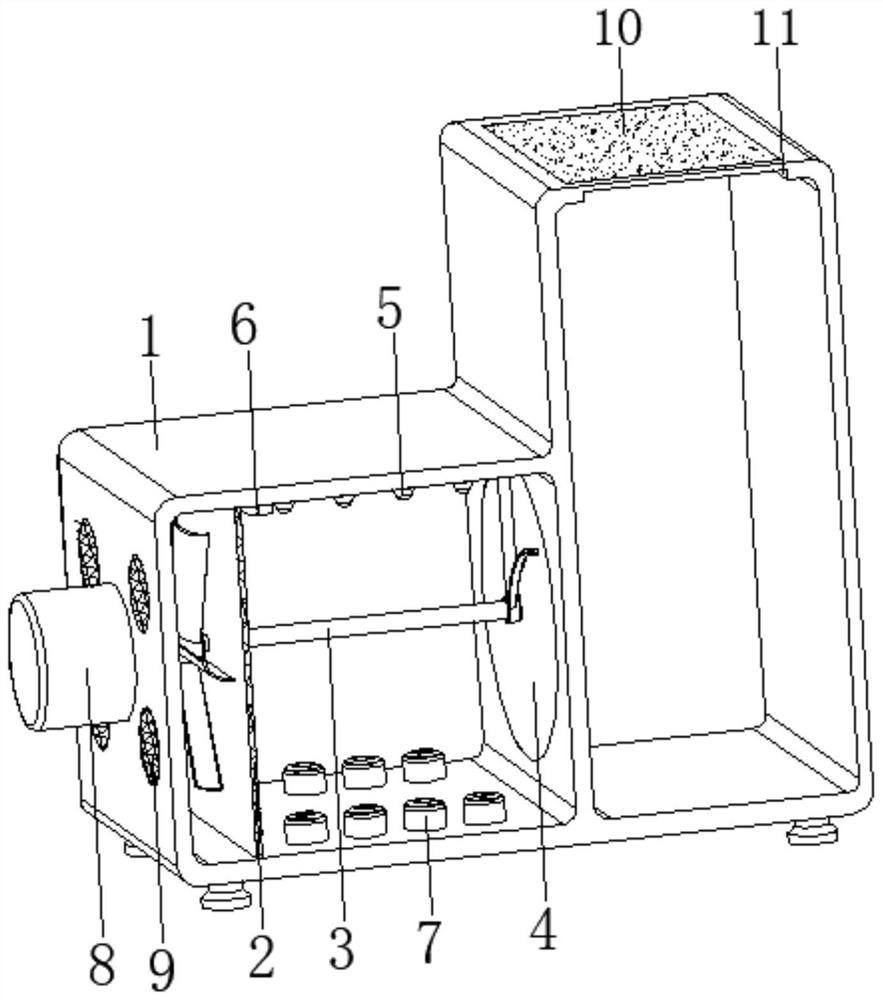

[0037] see Figure 1-Figure 8 , the present invention provides a technical solution: a fabric drape detector, comprising a body 1, a safety net 2, a processing device 3, and a cleaning device 4, characterized in that: the surface edge of the safety net 2 and the body 1 The inner wall is fixedly connected, the processing device 3 is arranged inside the body 1 and close to the position of the safety net 2, and the impurity removing device 4 is arranged inside the body 1;

[0038] The top side of the inner wall of the body 1 is provided with a laser generator 5, the top of the inner wall of the body 1 and a position close to the safety net 2 is fixedly connected with a cloth clamping mechanism 6, and the bottom of the inner wall of the body 1 corresponds to the laser generator 5. A laser receiver 7 is provided in place.

[0039] One end of the rotating shaft 31 penetrates the inner wall of the body 1 and extends to the outside thereof. A power mechanism 8 is provided on one side...

Embodiment 2

[0041] The processing device 3 is provided with a rotating shaft 31, a curved fan blade 32, and a cleaning device 33. The surface of the rotating shaft 31 is rotatably connected with the safety net 2, and one end of the rotating shaft 31 is rotatably connected with one side of the inner wall of the body 1. The end is fixed on the surface of the rotating shaft 31 and close to the position of the safety net 2, and the cleaning device 33 is arranged on the surface of the rotating shaft 31 and away from the side of the curved fan blade 32;

[0042] The cleaning device 33 is provided with an arc surface cover 331 , a scraper bar 332 , a magnetic rod 333 and a wiping device 334 . The edge is close to the side of the impurity removing device 4, and the wiping device 334 is arranged on the surface end of the rotating shaft 31 and is close to the position of the arc surface cover 331. When the cleaning device 33 is driven to rotate by the rotating shaft 31, the surface of the arc surfac...

Embodiment 3

[0046] The impurity removal device 4 is provided with a circular filter screen 41, an arc-shaped connecting rod 42, an elastic wire drawing 43, a magnetic block 44, and an impact device 45. The surface edge of the circular filter screen 41 is fixedly connected with the interior of the body 1, and the rotating shaft 31 is away from the curved surface. One end of the fan blade 32 is rotatably connected to the center of the surface of the circular filter screen 41, the top of the arc-shaped connecting rod 42 is hinged with the top of the surface of the circular filter screen 41, and the elastic wire 43 is fixed on the surface of the circular filter screen 41 and the arc. Between the two sides corresponding to the surface of the connecting rod 42, the surface side of the magnetic block 44 is fixedly connected with the surface side of the arc-shaped connecting rod 42, the magnetic block 44 and the magnetic rod 333 are arranged as magnetic poles with the same name, and the impact devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com