Quality management system for unvulcanized rubber material

A rubber material and quality management technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as the inability to produce unvulcanized rubber materials, the quality of unvulcanized rubber materials, and the long time required for inspection, so as to save manpower and material resources. Effects of wide application range and shortened detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the embodiments and the accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

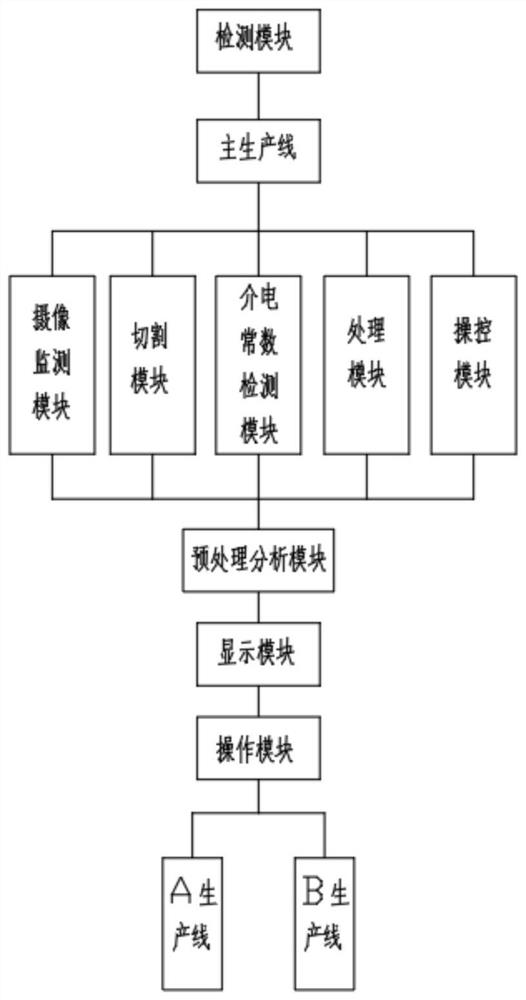

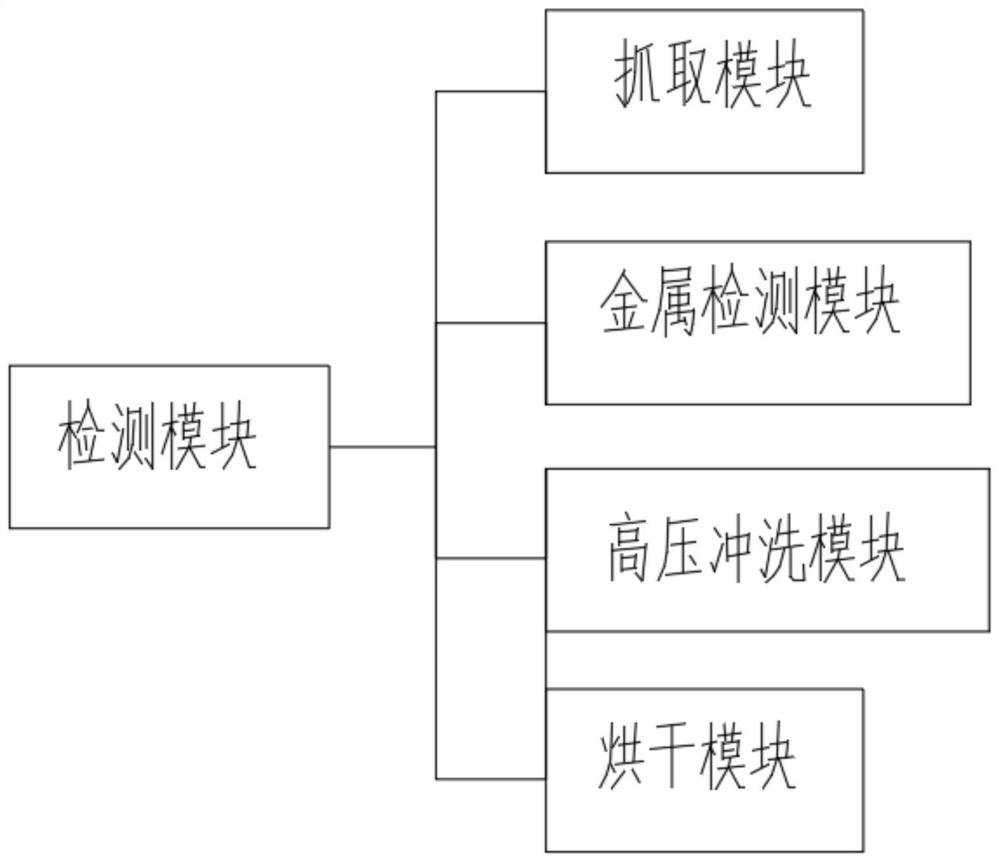

[0019] like Figures 1 to 2 As shown, a quality management system for unvulcanized rubber materials includes a detection module and an operation module, the detection module is connected with the main production line, and the main production line transmits the detection data and analysis data to the display module through the preprocessing analysis module, According to the data information on the display module, the operation module controls the unvulcanized rubber material to enter the A production line or the B production line. The display modules are computer display modules and mobile phone display modules.

[0020] The main produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com