Insulating flame-retardant anti-interference control cable

A technology for controlling cables and cables, applied in the direction of insulated cables, insulated conductors, cables, etc., can solve problems such as poor flame retardant effect, and achieve the effects of reducing the proportion of oxygen, enhancing structural strength, and speeding up fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

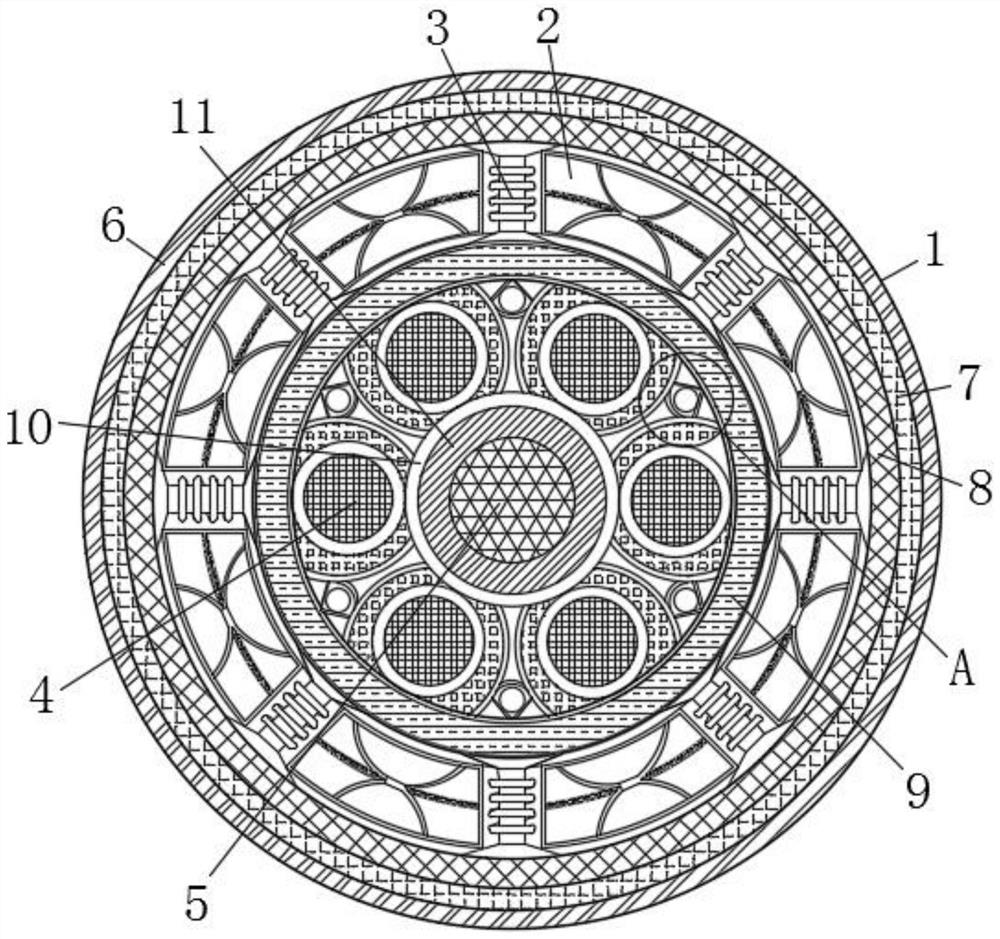

[0037] like Figure 1-7As shown, the present invention provides an insulating, flame-retardant and anti-interference control cable, including a cable body 1, a built-in flame-retardant device 2 is arranged inside the cable body 1, and a cut-resistant layer 8 is fixedly connected to the upper surface of the built-in flame-retardant device 2 , the bottom surface of the built-in flame retardant device 2 is fixedly connected with an insulating layer 9, and the insulating layer 9 has the effect of insulating protection. The interior of the cable body 1 is provided with an elastic support component 4, the cable body 1 will be squeezed, and the arc-shaped bearing spring 3 The top end of the spring is compressed inward under the external force. At this time, the radial spring rod 42 in the elastic support assembly 4 is also squeezed, so that the structure of the load spring 3 and the elastic support assembly 4 is deformed, and a reaction force is generated to offset the impact. Make t...

Embodiment 2

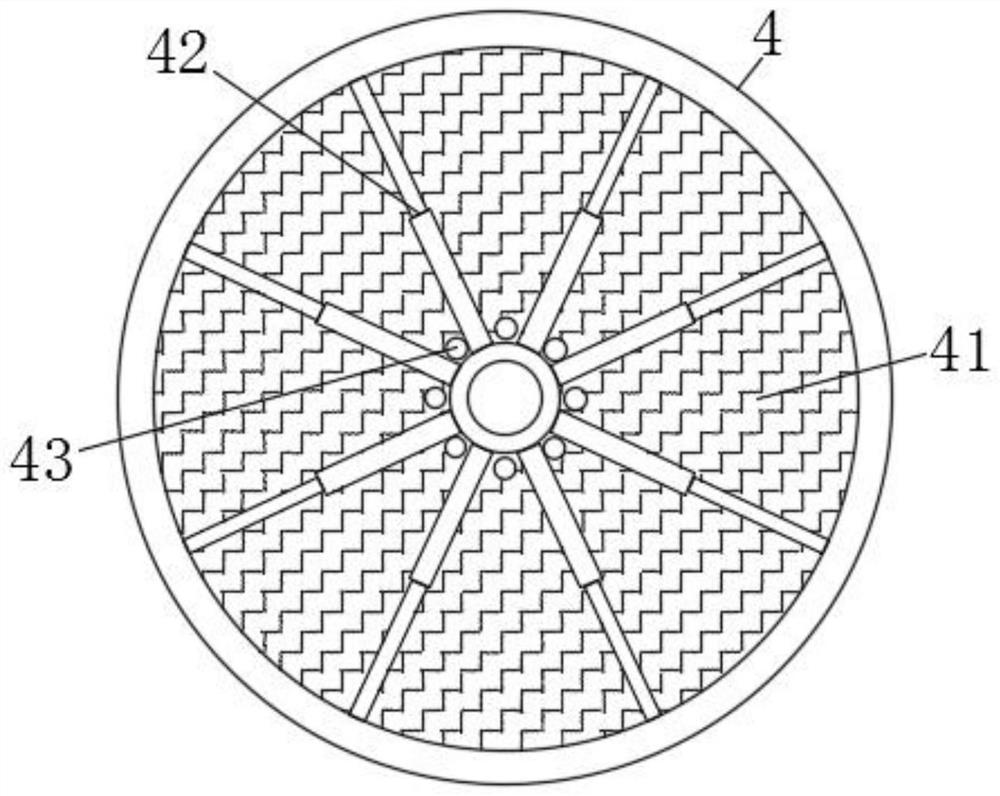

[0041] like Figure 1-7 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the side of the carrying container 24 away from the dry powder fire extinguishing agent 21 is provided with flame retardant particles 23, and the upper surface of the built-in flame retardant device 2 is provided with flame retardant particles 23. The rupture groove, the inner wall of the elastic support assembly 4 is fixedly connected with a radial spring rod 42, the bottom end side of the radial spring rod 42 is fixedly connected with a limit bar 43, and the radial spring rod 42 installed inside the elastic support assembly 4 is radially distributed, so that the elastic force The outer wall of the support assembly 4 bears the ground deformation impact to be dispersed, avoiding excessive local stress, exceeding the bearing range of the outer wall of the elastic support assembly 4, resulting in elastic fatigue of the elastic support assembly 4 and unable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com