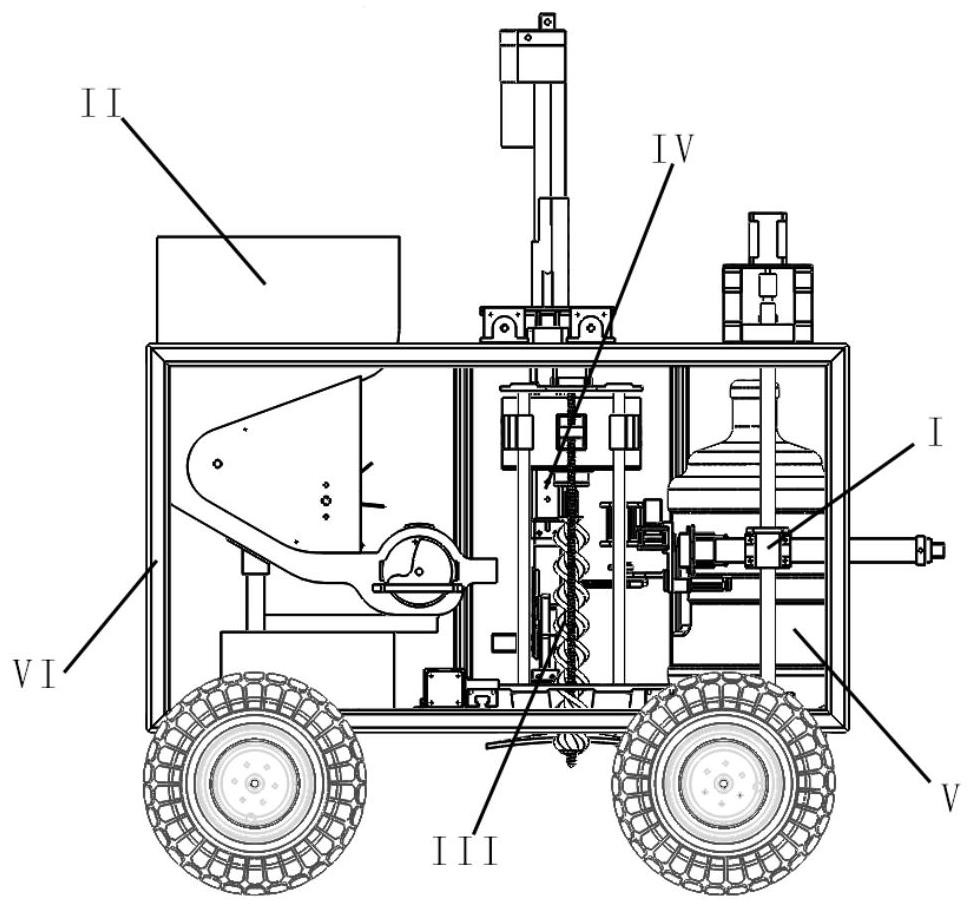

Automatic desert planting integrated vehicle

An integrated and desert technology, applied in the field of automated desert planting integrated vehicles, can solve the problems of cumbersome preparation work for automatic tree planting machinery, harsh working environment for artificial tree planting, and high cost of single-function machinery, to simplify preparation work, increase the number of plantings, and reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

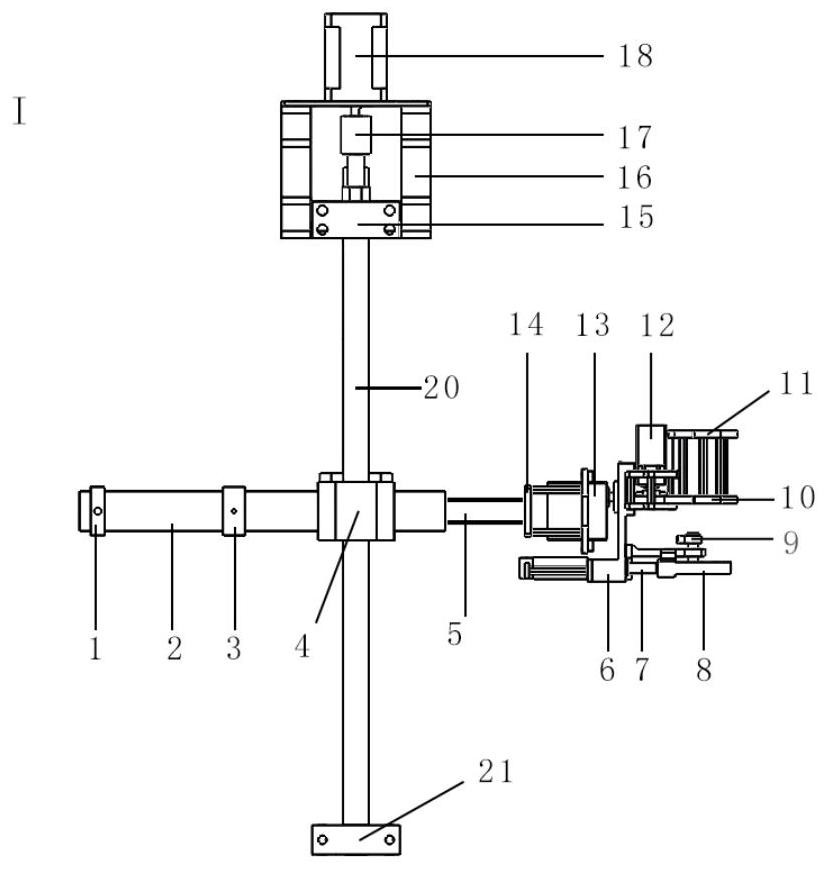

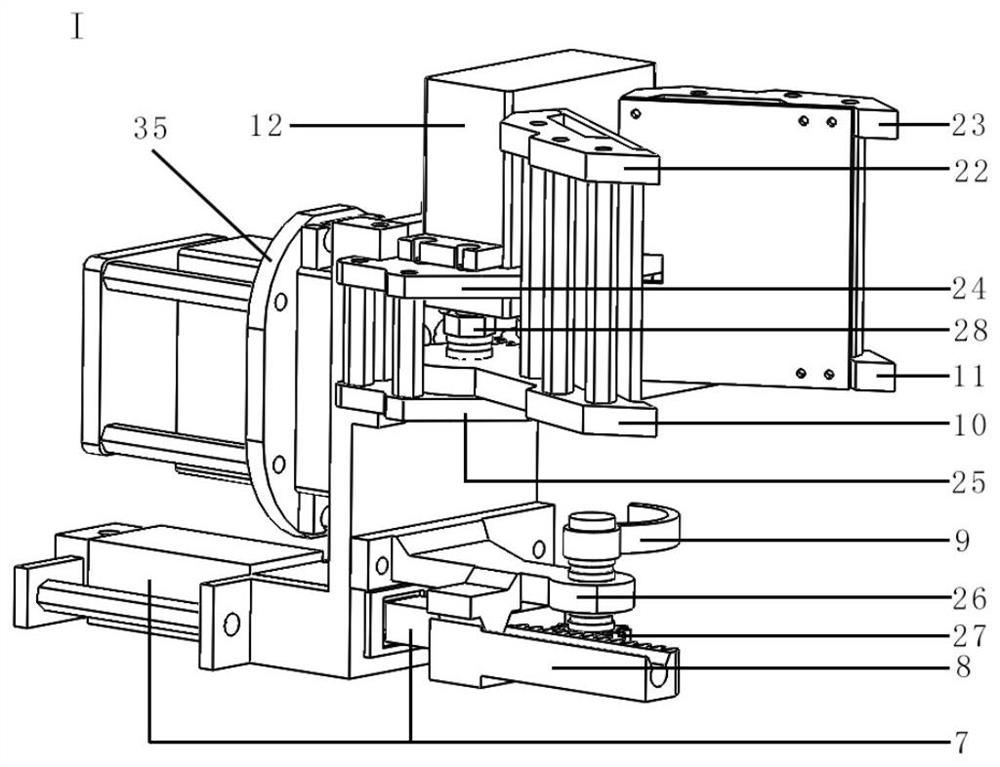

[0050] When the present invention is used, firstly, the automatic desert planting integrated vehicle of the present invention is moved to the position to be planted.

[0051] The horizontal stepping motor D70 of the drilling pit device III is started, and the horizontal screw 69 rotates, which drives the drilling pit device III to move along the guide rail 67 to the working position and then stops. The vertical stepping motor C58 and the DC motor 62 are activated, and the drill bit starts to rotate and simultaneously Descend, reach the predetermined depth, stop, drill out the seedling planting pit; and return to the standby position along the original route.

[0052] The seedlings are first stacked in the storage body 43 of the storage device II, and flow to the separation device 44 along the "y"-shaped channel. The stepping motor B48 starts to start, driving the rotating shaft 49, the lower paddle 51 and the rotating shaft gear 50, and the rotating shaft gear 50 drives the baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com