Bone filling bag and preparation method thereof

A technology for filling sacs and balloons, used in bone implants, fixators, joint implants, etc., can solve problems such as difficulty in taking out the sac bag, and achieve the effects of high pore density, good mechanical properties, and improved dispersion force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

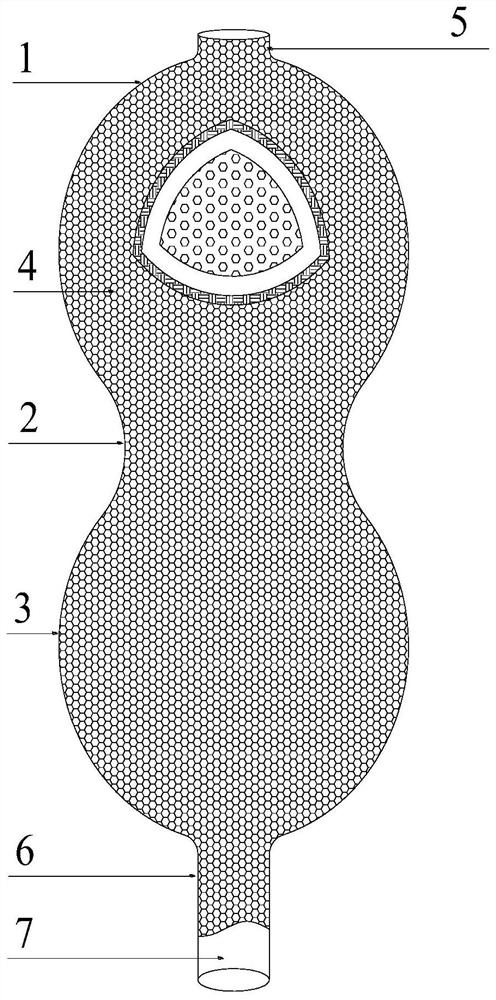

[0072] like figure 1 , a bone-filled pouch, the pouch is provided with a double-layer mesh structure from the inside to the outside, and each layer of the mesh structure includes a first balloon 1, a second balloon 3, and is connected to the first balloon 1 and the waist structure 2 of the second balloon 3; several holes 4 are provided on the mesh structure of each layer, and the apertures of the holes 4 on the mesh structure are sequentially from the inner layer to the outer layer. Decrease.

[0073] The hole diameter of the holes 4 on the mesh structure of the inner layer is 0.8mm; the hole diameter of the holes 4 on the mesh structure of the outer layer is 0.05mm; the hole density of the holes 4 on the mesh structure is 6 / cm 2 ; the radius of the cross-section of the waist structure 2 is smaller than the radius of the cross-section of the first balloon 1 and the second balloon 3; the volume of the first balloon 1 or the second balloon 3 is 48cm 3 ; The thickness of eac...

Embodiment 2

[0082]A bone-filled bag, the bag is provided with three layers of mesh structures from the inside to the outside, and each layer of the mesh structure includes a first balloon 1, a second balloon 3, and connects the first balloon 1 and the The waist structure 2 of the second balloon 3; each layer of the mesh structure is provided with a plurality of holes 4, and the apertures of the holes 4 on the mesh structure decrease sequentially from the inner layer to the outer layer.

[0083] The hole diameter of the holes 4 on the mesh structure of the inner layer is 0.1mm; the hole diameter of the holes 4 on the mesh structure of the outer layer is 0.01mm, and the hole diameter of the holes 4 on the mesh structure of the middle layer is 0.05mm. ; The hole density of the holes 4 on the mesh structure is 10 / cm 2 ; the radius of the cross-section of the waist structure 2 is smaller than the radius of the cross-section of the first balloon 1 and the second balloon 3; the volume of the fir...

Embodiment 3

[0092] A bone-filled pouch, the pouch is provided with four layers of mesh structures from the inside to the outside, and each layer of the mesh structure includes a first balloon 1, a second balloon 3, and is connected to the first balloon 1 and the waist structure 2 of the second balloon 3; a plurality of holes 4 are provided on the mesh structure of each layer, and the apertures of the holes 4 on the mesh structure decrease sequentially from the inner layer to the outer layer .

[0093] The hole diameter of the holes 4 on the mesh structure of the inner layer is 10mm; the hole diameter of the holes 4 on the mesh structure of the outer layer is 1mm, and the hole diameter of the holes 4 on the mesh structure of the middle layer is from the inside to the outside. 7mm and 4mm respectively; the hole density of the holes 4 on the mesh structure is 1 / cm 2 ; the radius of the cross-section of the waist structure 2 is smaller than the radius of the cross-section of the first balloo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com