Material distribution type aluminum ingot pouring forming mold and pouring method

A technology for forming molds and aluminum ingots, which is applied in the direction of manufacturing tools, ingot casting workshops, and equipment for feeding molten metal into molds, etc., can solve problems such as low production efficiency and discontinuous production process, and achieve high production efficiency, The effect of continuous casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

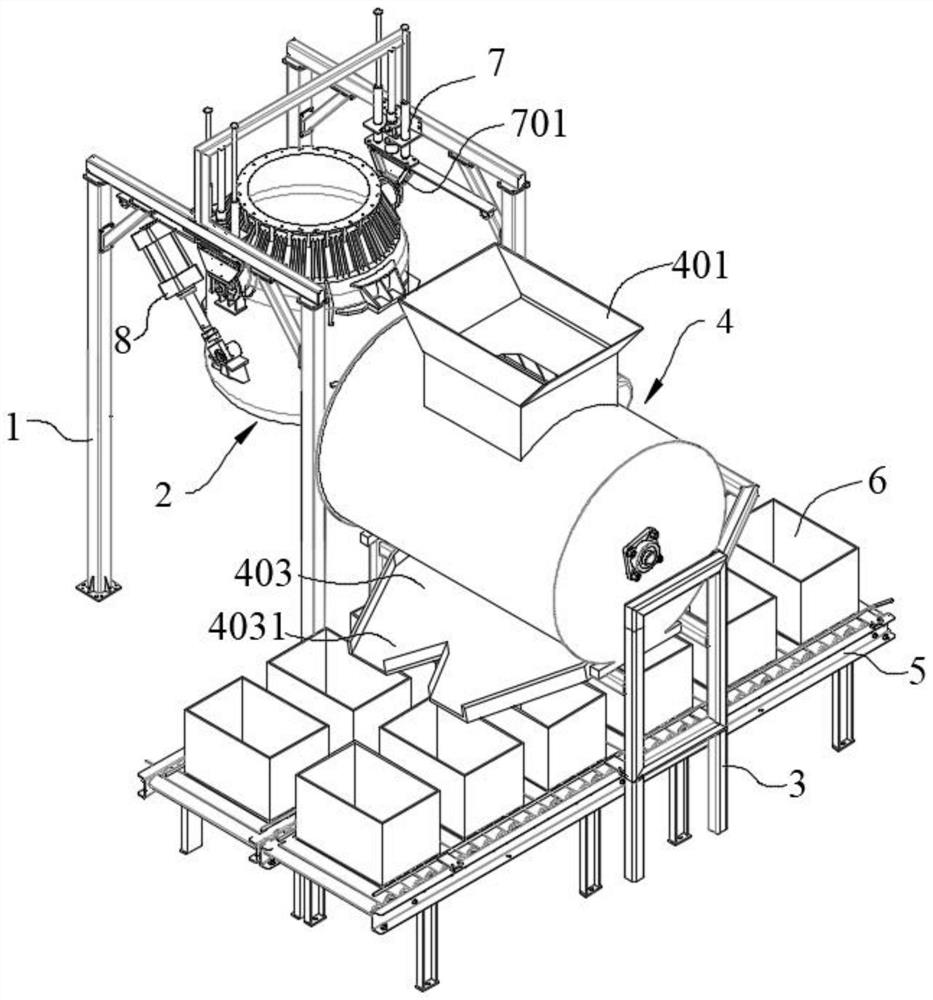

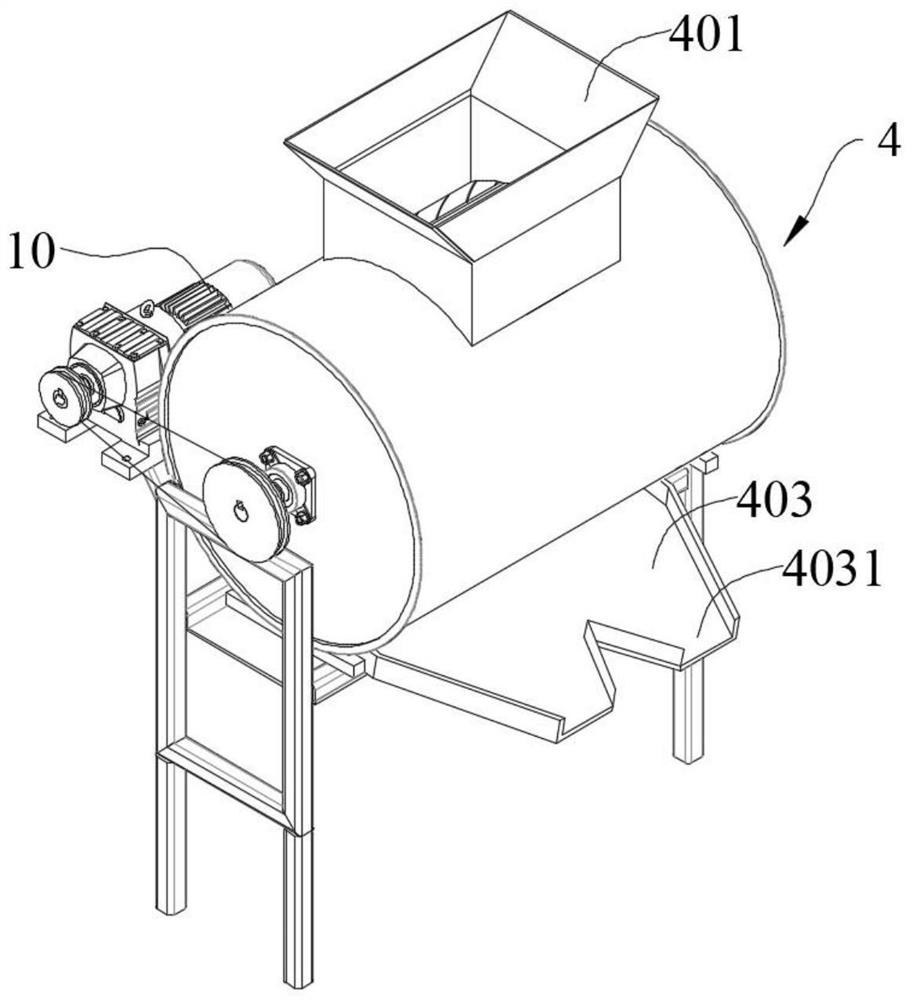

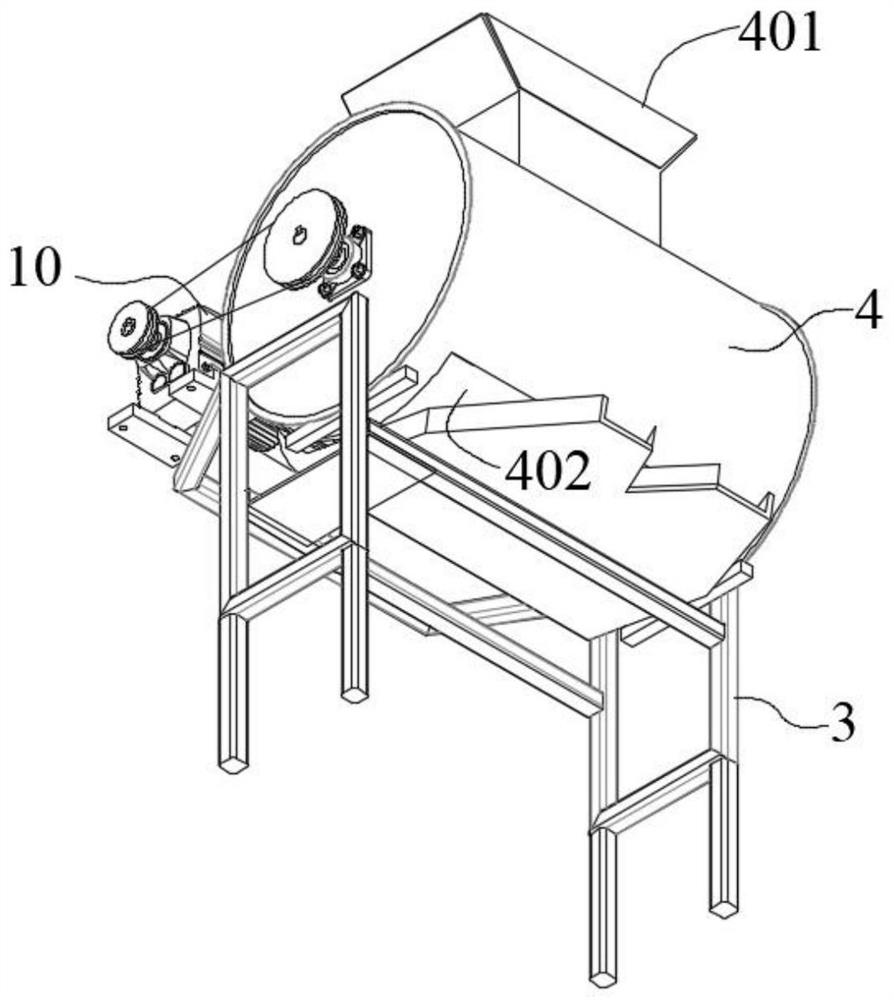

[0041] see figure 1 As shown, the present invention is a material-distributed aluminum ingot casting molding die and a pouring method, including a furnace mechanism, a material-distribution mechanism and a molding mechanism, the material-distribution mechanism is fixedly installed on one side of the furnace mechanism, and the molding mechanism is installed on the material-distributing mechanism. below. Through the material distribution mechanism, the molten aluminum poured by the melting furnace mechanism is simultaneously distributed into multiple forming molds to realize the simultaneous casting of multiple aluminum ingots. During the material distribution process, the melting furnace mechanism has reworked to melt the next batch of raw materials, realizing continuous casting and high production efficiency. .

[0042] see figure 1As shown, the furnace mechanism includes a furnace support 1 and a furnace body 2, a lifting cylinder 7 is fixedly installed on both sides of the...

Embodiment 2

[0055] Based on the first embodiment, the difference between the second embodiment is:

[0056] see Figure 7 As shown, a heating ring 404 is wound around the periphery of the distribution tank 4 to keep the molten aluminum poured into the distribution tank 4 warm, so as to avoid premature cooling of the aluminum liquid and affect the fluidity of the aluminum liquid in the distribution tank 403 . At the same time, the peripheral side of the sub-tank 9 is matched with the inner wall of the material distribution tank 4 with a minimum gap of 1 cm, so that the sub-tank 9 can fully receive the heat transmitted by the heating ring and ensure the thermal insulation performance of the sub-tank 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com