Method of making adaptable carbon fiber beam

A technology of carbon fiber and unidirectional carbon fiber, which is applied in engine manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of small reinforcement stiffness and output power limitation, achieve good bending load, increase manufacturing cost, and increase length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

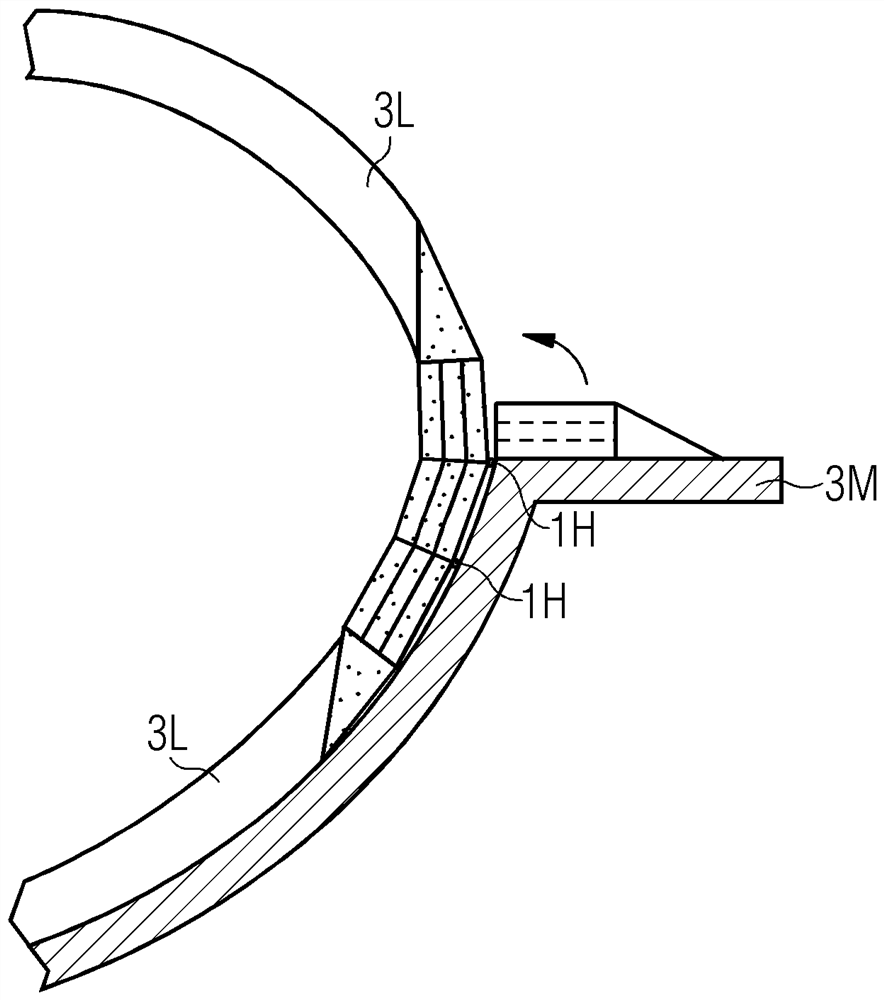

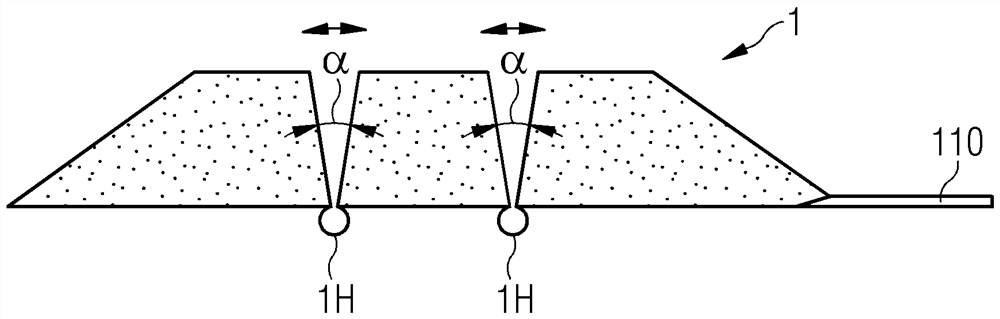

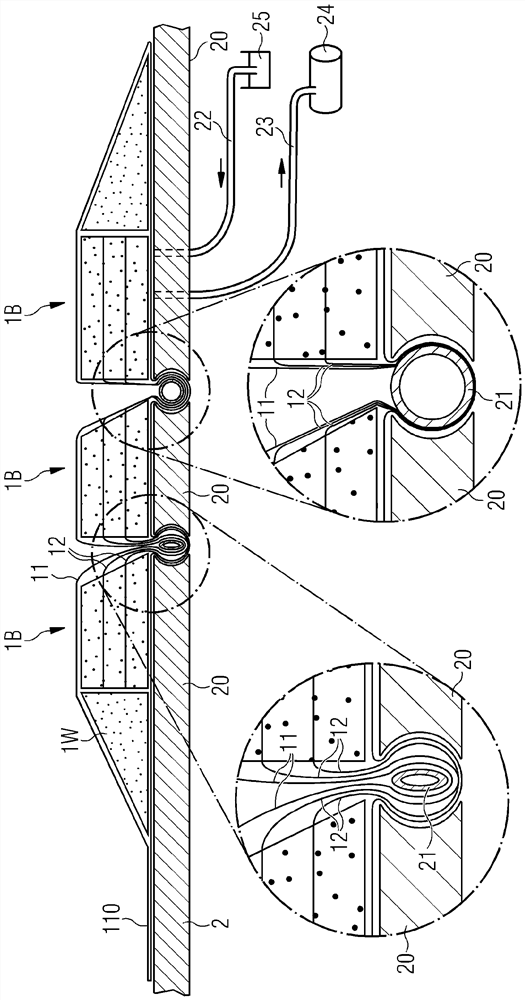

[0040] figure 1 A series of sections through the wind turbine rotor blade 8 is shown, starting from section 81 through the circular root region 80R and progressing to section 85 through the airfoil region. As shown in sections 81-84, the shape of the rotor blades transitions in a complex manner from an initial circular shape. This inner portion of the rotor blade is referred to as the "transition region" or "shoulder region" and must be dimensioned to withstand the high bending moments during normal operation of the wind turbine as well as during high wind conditions. A common approach is to make the rotor blade shell very thick in the transition zone, but the added composite material adds weight to the rotor blade. Alternatively, reinforced structures embedded in lightweight but rigid materials such as wood are known, but these structures are time consuming and expensive to manufacture. In another method like figure 2 As shown in the wireframe representation in , a lightw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com