Rack supporting device of automobile steering device

A technology of automobile steering gear and support device, which is applied in the direction of mechanical steering gear, etc., which can solve the problems of affecting the meshing operation of rack and pinion, affecting the driving experience of the driver, and the wear of surface PTFE, so as to improve the driving experience and facilitate the adjustment of preload , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

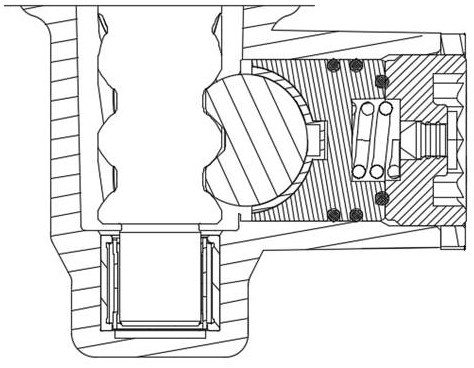

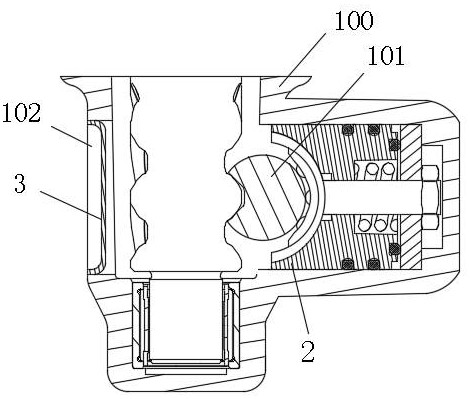

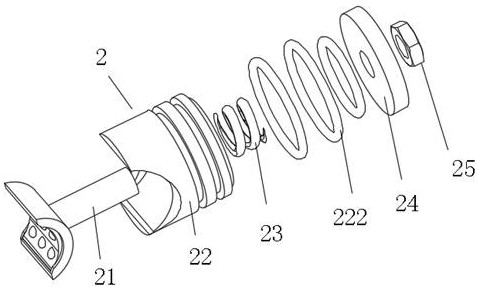

[0020] see Figure 2-6 , the present invention provides a technical solution: a rack support device for an automobile steering gear, comprising a rack 101 and a gear set in the steering gear housing 100, and a steering gear housing 100 located on the back of the rack 101 is provided with The pressure block assembly accommodating cavity, the pressure block assembly accommodating cavity is a circular cavity structure, the diverter housing 100 is located at the end of the circular cavity with a let-away groove, and the let-away groove and the circular cavity are A stepped surface is formed, a rack pressure block assembly 2 is arranged in the pressure block assembly accommodating cavity, and the rack pressure block assembly 2 includes a rolling body support assembly 21 and a pressure block 22; the rolling body support assembly 21 includes an arc plate-shaped The rolling frame 211 of the structure, the arc surface of the front end of the rolling frame 211 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com