Disk taking mechanism, warehouse type taking and storing equipment applying same and taking and storing method

A tray and storage technology, applied in the field of storage-type storage equipment, can solve the problems of large area of storage and storage equipment, unfavorable promotion and use, occupying a large space, etc., and achieves a simple solution, simple and practical solution, and reduced space occupation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

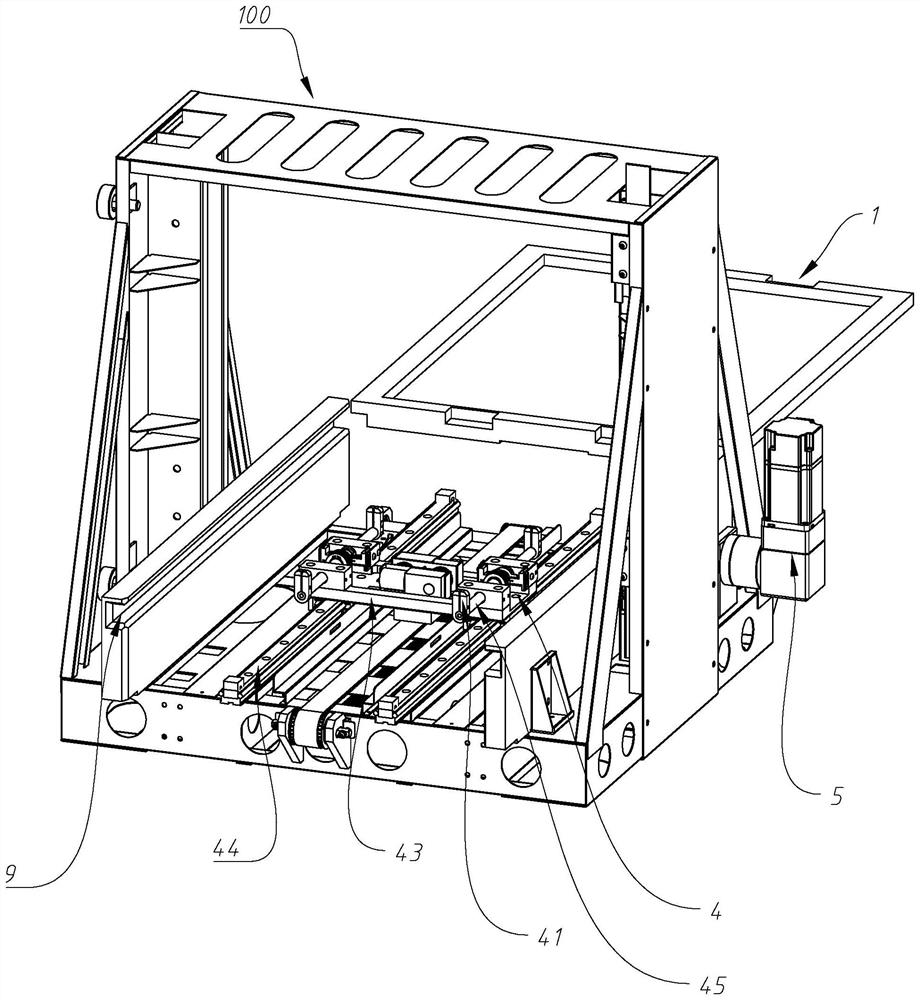

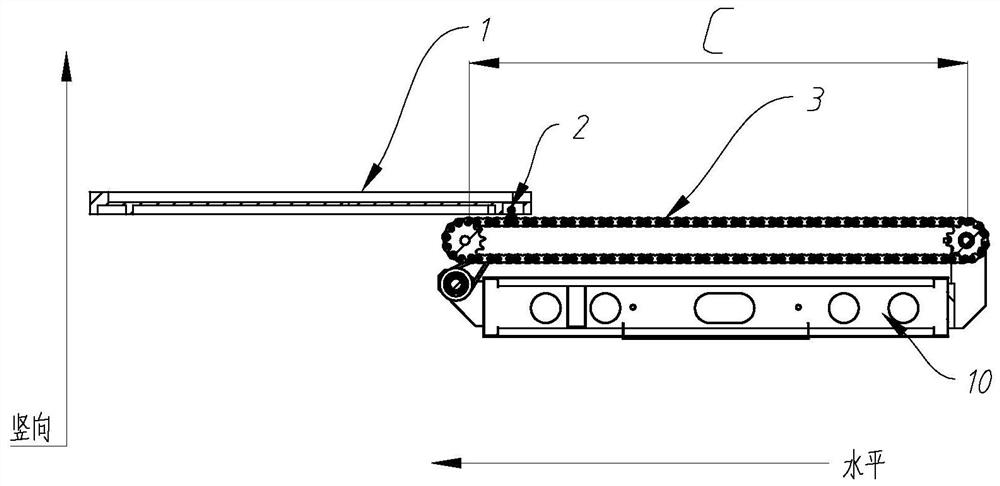

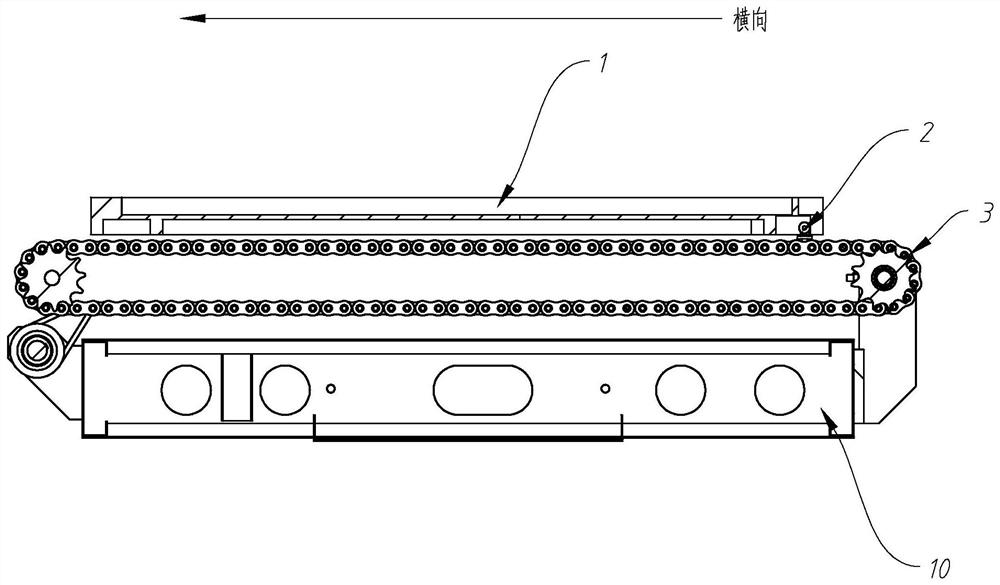

[0111] A tray-taking mechanism, comprising a storage tray 1, a fork assembly 4 for pulling the storage tray 1, and a finger hook assembly for driving the storage tray 1 to move;

[0112] The fork assembly 4 includes a protruding body 41 for contacting or hooking the storage tray 1 , a rod 45 for extending the extension range of the protruding body 41 , and a rotating motor for driving the rod 45 and the protruding body 41 to rotate. 42. The bottom plate 43 for assembling the rotary motor 42 and the synchronous belt 72 for driving the bottom plate 43 to move;

[0113] The rod, the convex body and the rotating motor form a fork structure; the rod and the convex body form a fork.

[0114] The finger hook assembly includes a hook member 2 for contacting or hooking the storage tray 1, and a chain 3 for driving the hook member 2 to move back and forth;

[0115] The timing belt 72 is fixedly connected with the bottom plate 43 of the fork assembly 4;

[0116] The chain 3 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com