Subway station structural crack repairing and reinforcing method and reinforcing part

A subway station and structural technology, applied in the repair of basic structures, underwater structures, basic structure engineering, etc., can solve problems such as cracking at cracks, poor durability of reinforcement and repair, and improve waterproofness and tensile strength Intensity, increasing overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

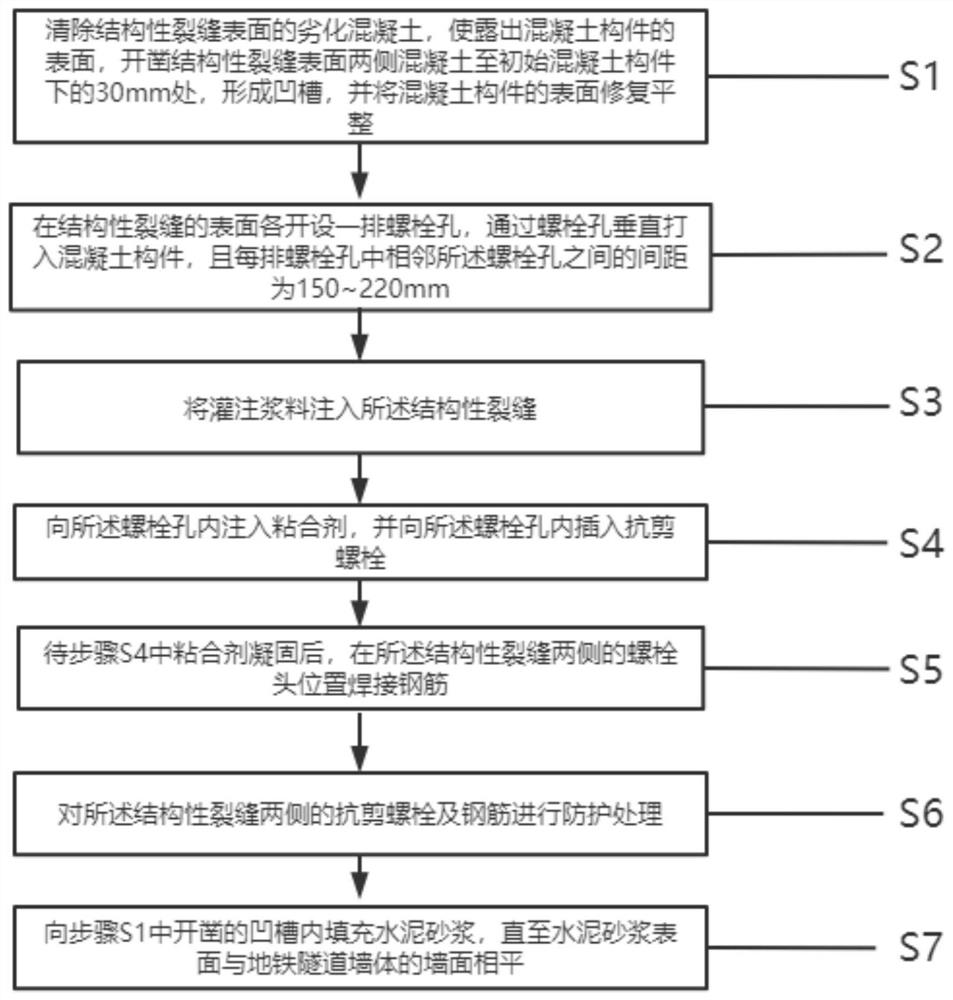

[0043] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a method for repairing and strengthening structural cracks in a subway station includes the following steps:

[0044] S1: Remove the degraded concrete on the surface of the structural crack to expose the surface of the concrete member, excavate the concrete on both sides of the surface of the structural crack to 30mm below the initial concrete member, form a groove, and repair and smooth the surface of the concrete member;

[0045] S2: A row of bolt holes is opened on the surface of the structural crack, and the concrete members are vertically driven through the bolt holes, and the spacing between the adjacent bolt holes in each row of bolt holes is 150-220mm;

[0046] S3: injecting the grouting slurry into the structural crack;

[0047] S4: inject adhesive into the bolt holes, and insert shear bolts into the bolt holes;

[0048] S5: after the adhesive is solidified in step S4, welding steel bars at the pos...

Embodiment 2

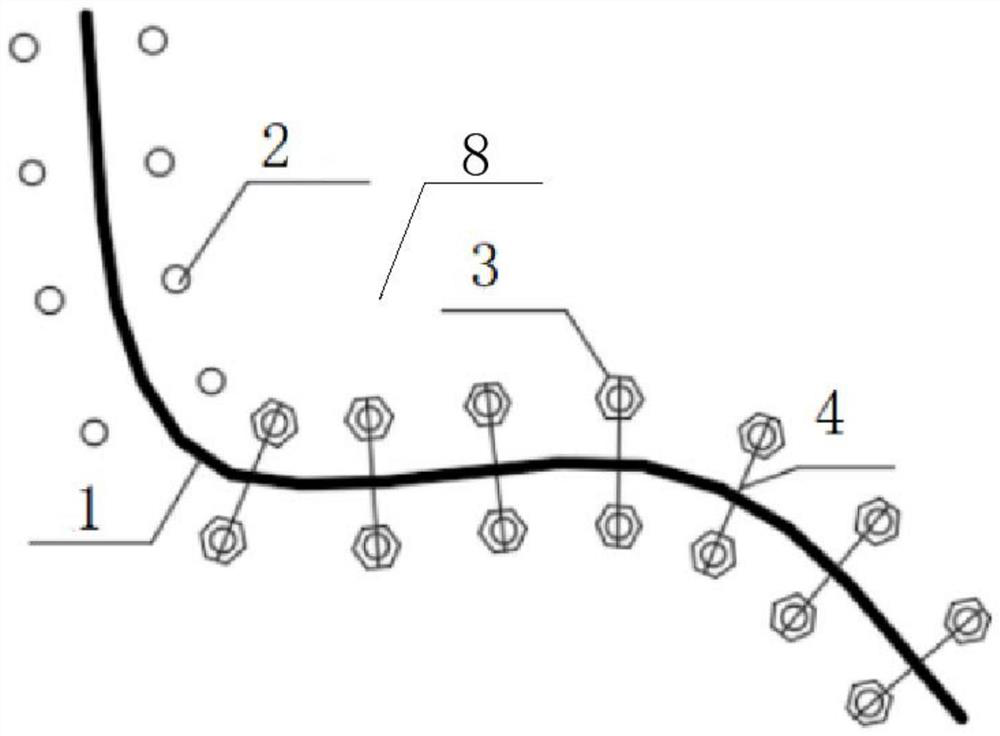

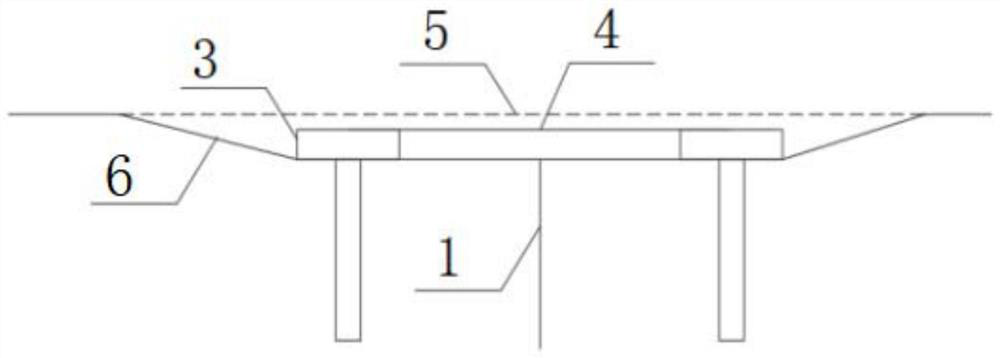

[0064] A structural crack repair reinforcement for a subway station, comprising a concrete member 8, a bolt hole 2, and a shear bolt 3, the concrete member 8 is located at a structural crack, and the structural crack divides the concrete member 1 into two parts, Two sides of the structural crack are provided with grooves, and the grooves are filled with a cement mortar layer;

[0065] Both sides of the structural crack are provided with bolt holes 2, a plurality of bolt holes 2 are distributed in a row, the bolt holes 2 are filled with adhesive, and the bolt holes 2 are inserted with shear bolts. 3. The shear bolts 3 on both sides of the structural crack are fixed by steel bars 4 .

[0066] The grooves are formed by excavating the concrete on both sides of the structural crack to 30 mm below the surface of the initial concrete member 5 , and the concrete member 6 is excavated after the concrete member is excavated.

[0067] The spacing between adjacent bolt holes 2 on the sam...

Embodiment 3

[0072] In this embodiment, on the basis of Embodiment 1, the extensive reinforcement of the surface of the concrete member 8 is further increased to increase the integrity of the concrete member 8 on both sides of the structural crack 1 . A carbon fiber cloth 7 is laid on the surface of the concrete member 1 , and the carbon fiber cloth 7 includes a transverse carbon fiber cloth and a longitudinal carbon fiber cloth, and the carbon fiber cloth 7 is vertically interlaced with the longitudinal carbon fiber cloth. The laying method of the carbon fiber cloth is as follows: in the direction of the vertical crack, laying 2500mm on both sides of the edge of the structural crack; in the direction parallel to the crack, laying 500mm beyond the end of the structural crack, in the direction of the vertical structural crack and Double-layer carbon fiber cloth is used for each direction parallel to the structural cracks.

[0073] The installation of carbon fiber cloth enhances the integrit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com