Rail-mounted continuous pipe operation machine

A coiled tubing and track-type technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of reduced frequency of long-distance transportation, reduced use of chassis vehicles, and long time spent, so as to reduce the complexity of wellhead installation Operational and construction risks, reduced operating costs, and the effect of reduced personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

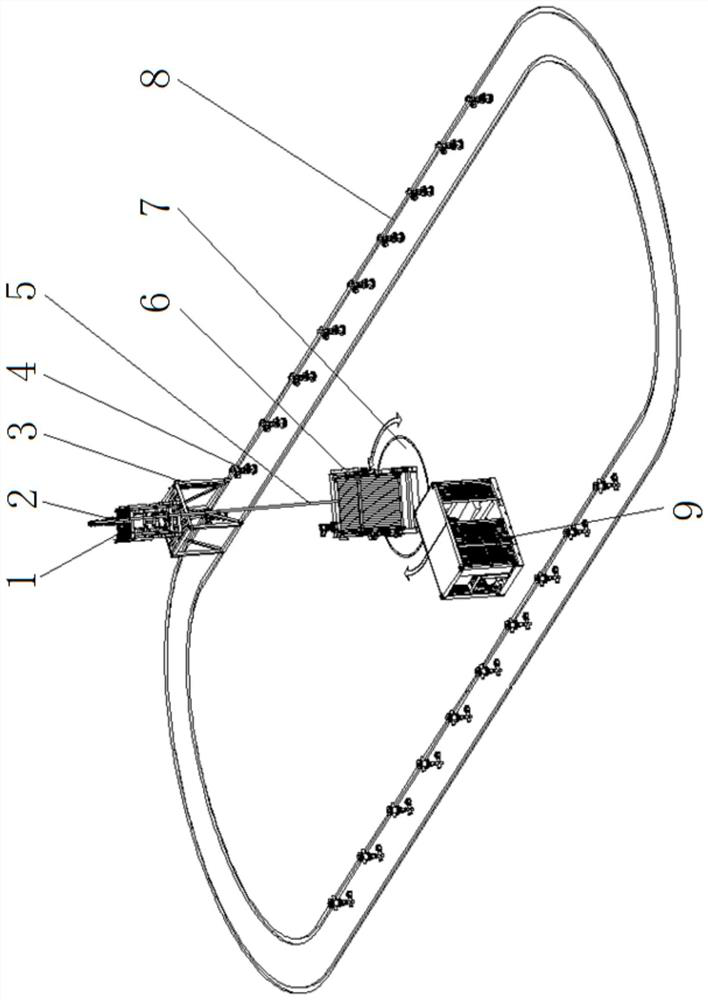

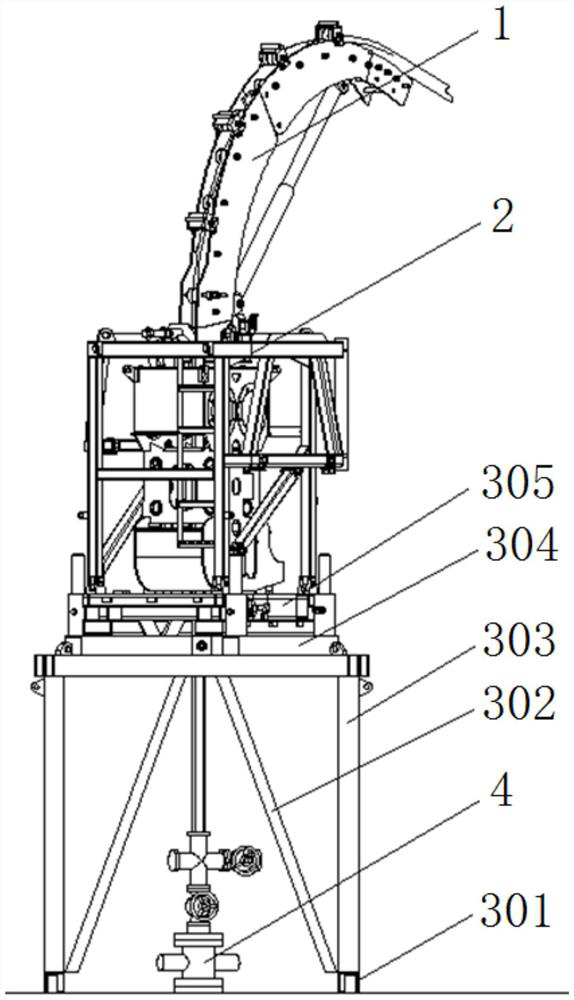

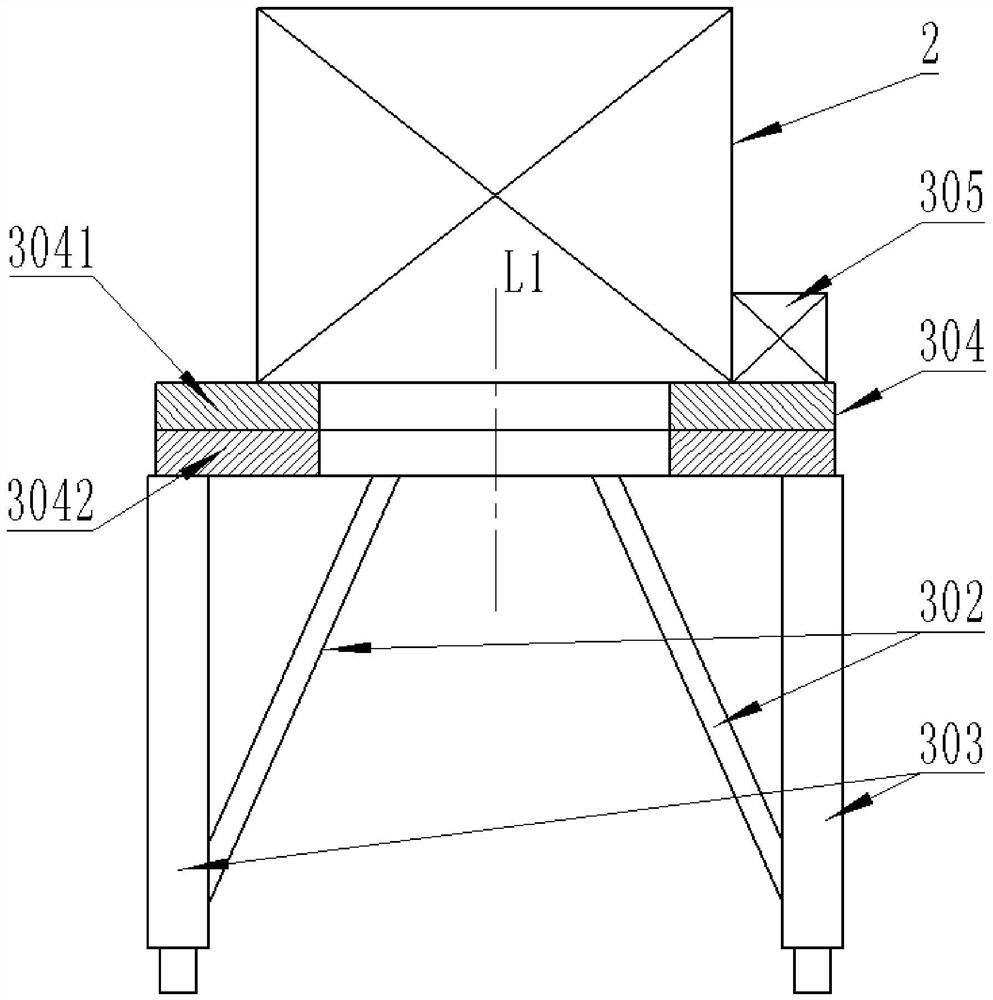

[0022] An orbital coiled tubing machine, comprising a guide 2, an injection head 1, a multifunctional rotating tower 3 and a first track 8 arranged in sequence from top to bottom, the first track 8 extending along the arrangement direction of a row of wellheads 4 , the multifunctional rotating tower 3 can drive the guide 2 and the injection head 1 to walk on the first track 8, and the multifunctional rotating tower 3 can also drive the injection head 1 to rotate around a first straight line, and the first straight line is upright position, such as figure 1 and figure 2 shown.

[0023] In this embodiment, the first track 8 is a double track structure, the first track 8 includes two steel rails that are parallel to each other, and the wellhead 4 is located between the two steel rails. The arrangement of the first rails 8 may depend on the arrangement direction of the wellheads 4 , and the first rails 8 may be arranged in a closed annular structure (such as a rectangle or a ra...

Embodiment 2

[0036]This embodiment is a modification of Embodiment 1. The main difference between this embodiment and Embodiment 1 is that:

[0037] The orbital coiled tubing machine also includes a drum 6, a drum self-propelled platform 10 and a second rail 11 that are sequentially connected from top to bottom. The second rail 11 and the first rail 8 are arranged in a horizontal direction, and the drum self-propelled platform 10 It can drive the roller 6 to walk on the second track 11, and the roller 6 can cooperate with the guide 2 and the injection head 1 to lift the continuous pipe 5, such as Figure 4 shown.

[0038] This embodiment does not contain the rotating platform 7 in the first embodiment, and the rotating platform 7 in the first embodiment is replaced by the roller self-propelled platform 10 and the second rail 11 in this embodiment. The second rail 11 and the first rail 8 may be arranged in parallel, and the second rail 11 and the first rail 8 may also be arranged perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com