Lightweight composite cooling thrust chamber body device

A composite cooling and thrust chamber technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as limited weight reduction and thermal structure damage, and achieve improved performance, high connection strength, and reliable thermal protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In this embodiment, "front" and "rear" are along the gas flow direction, the gas coming from is front, and the gas going back.

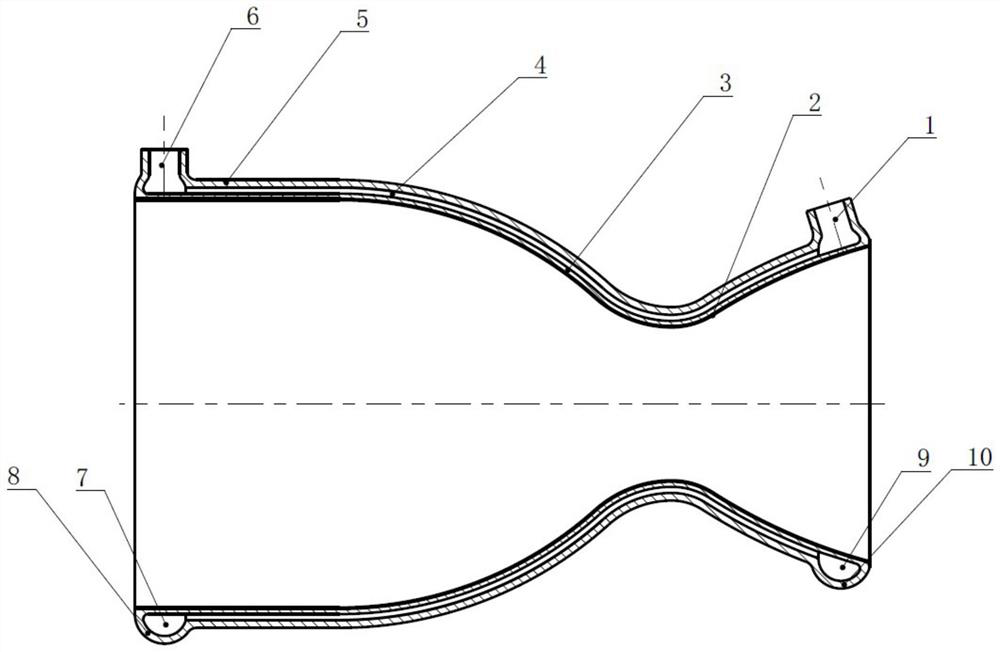

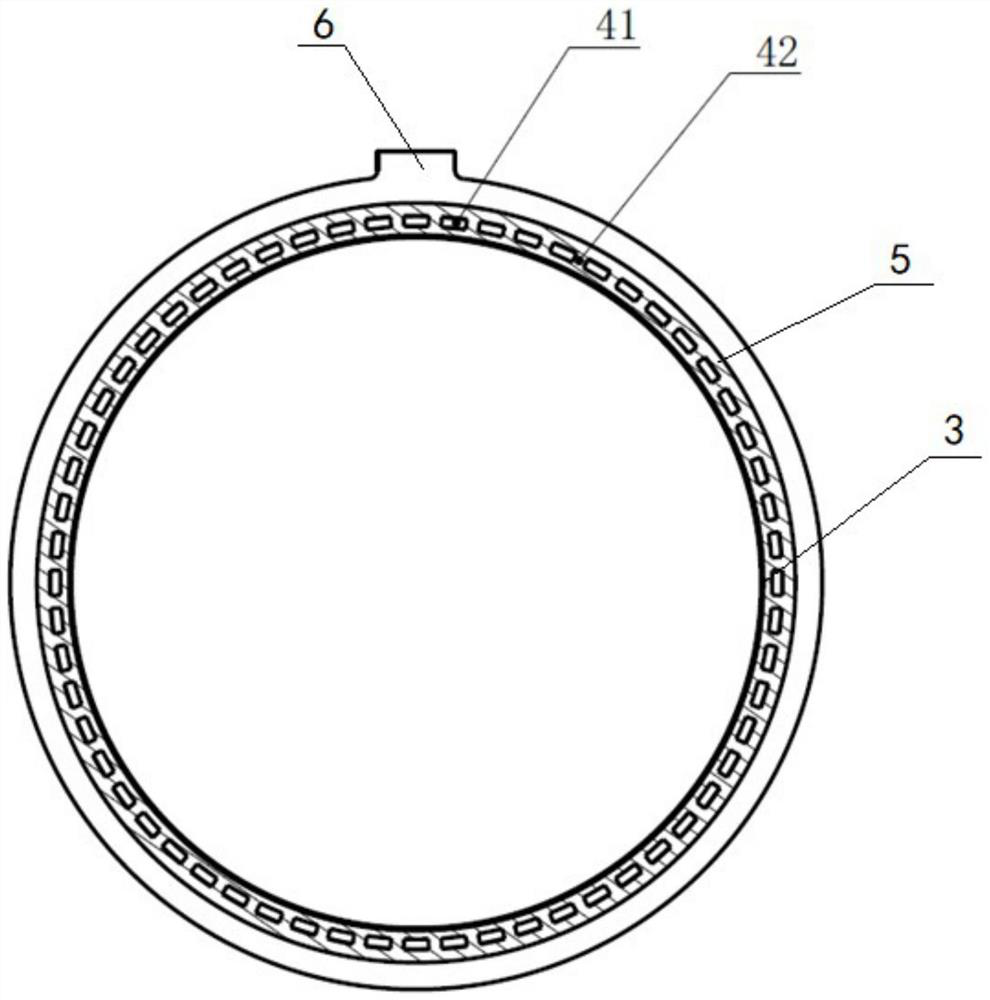

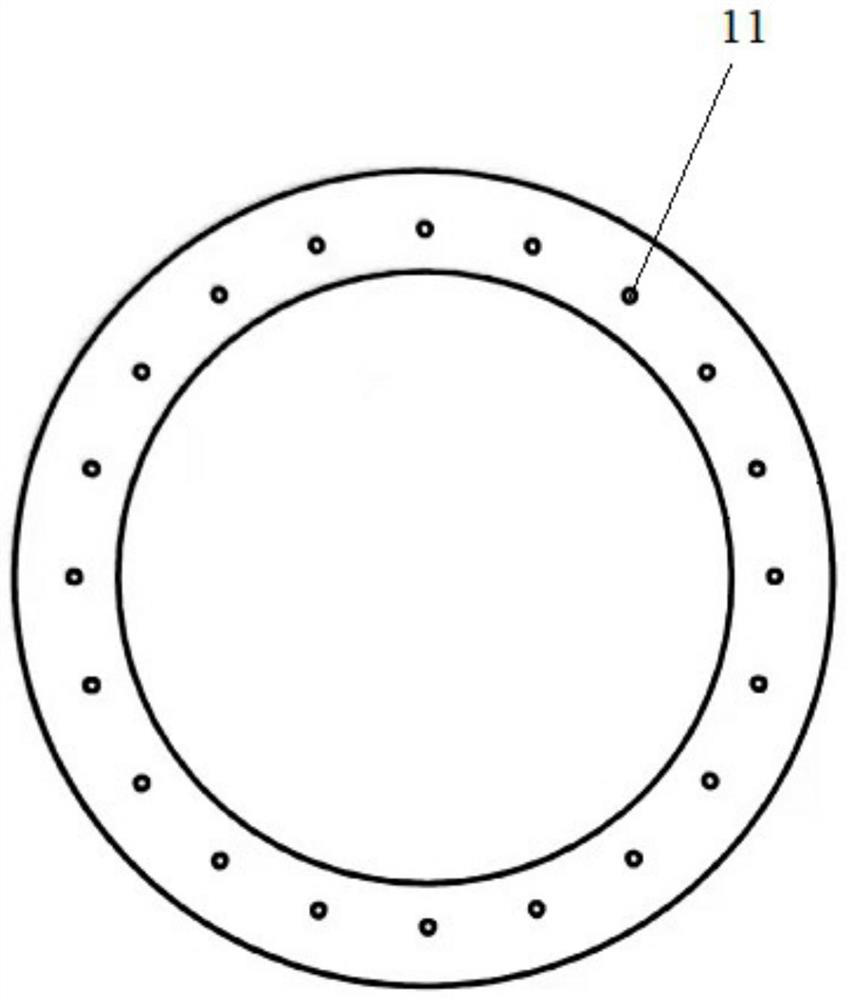

[0039] see figure 1 and figure 2 , this embodiment provides a lightweight composite cooling thrust chamber body device, including a high temperature anti-oxidation thermal barrier coating 2, an inner wall 3, a cooling jacket 4 and an outer wall 5 sequentially arranged from inside to outside; the thickness of the inner wall 3 It is 0.8mm~1.5mm; among them, the inner wall 3, the cooling jacket 4 and the outer wall 5 are integrally formed by 3D printing technology, so that the number of welds for preparing the thrust chamber body is reduced from 150 to 0, and the number of parts is reduced to 1 , the connection strength of the inner wall 3 and the outer wall 5 is higher, which is more conducive to realizing reliable thermal protection of the body.

[0040] The high-temperature anti-oxidation thermal barrier coating 2 includes an MCrAlY anti-ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com