Method for detecting flowability of SCR (Selective Catalytic Reduction) denitration catalyst pug

A technology of SCR catalysts and denitrification catalysts, applied in the field of SCR catalysts, can solve the problems of inability to form control means, quantification, and no unified detection method for fluidity of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

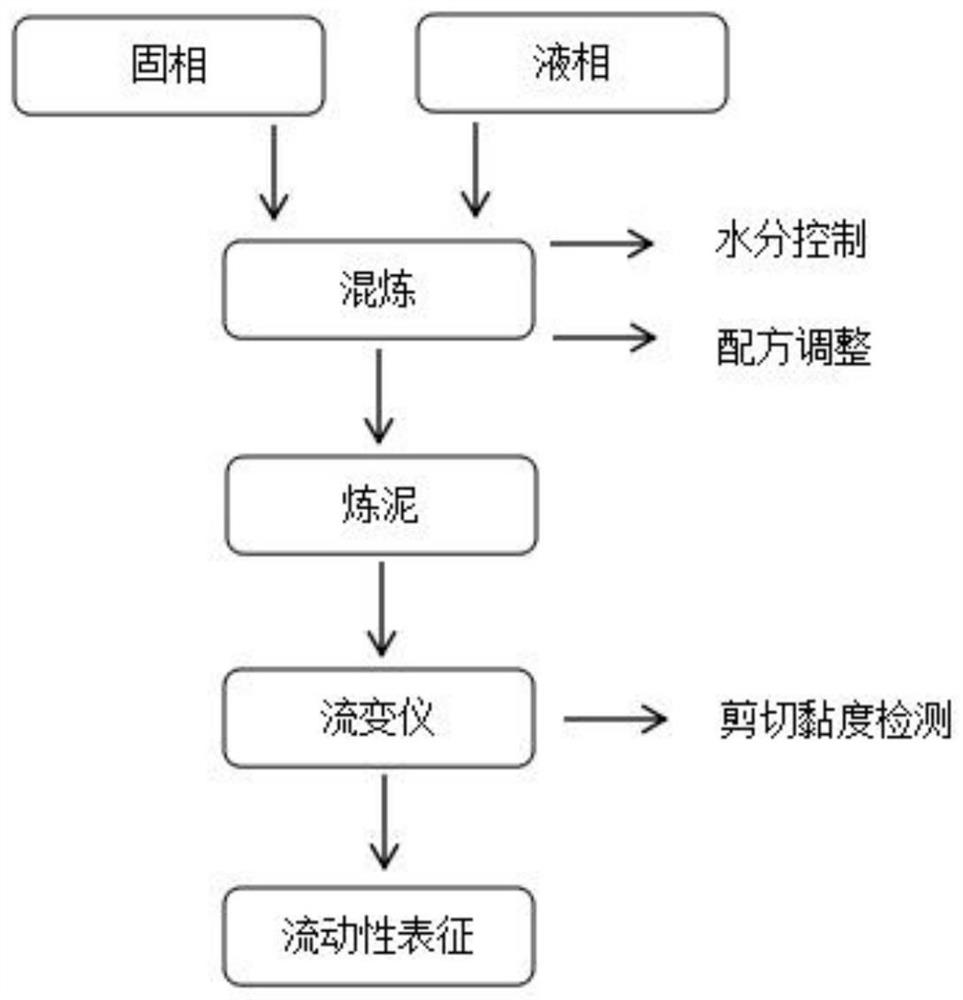

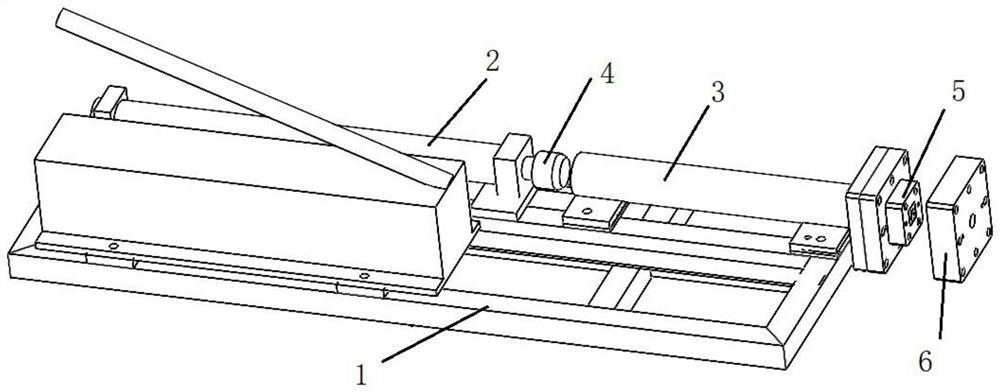

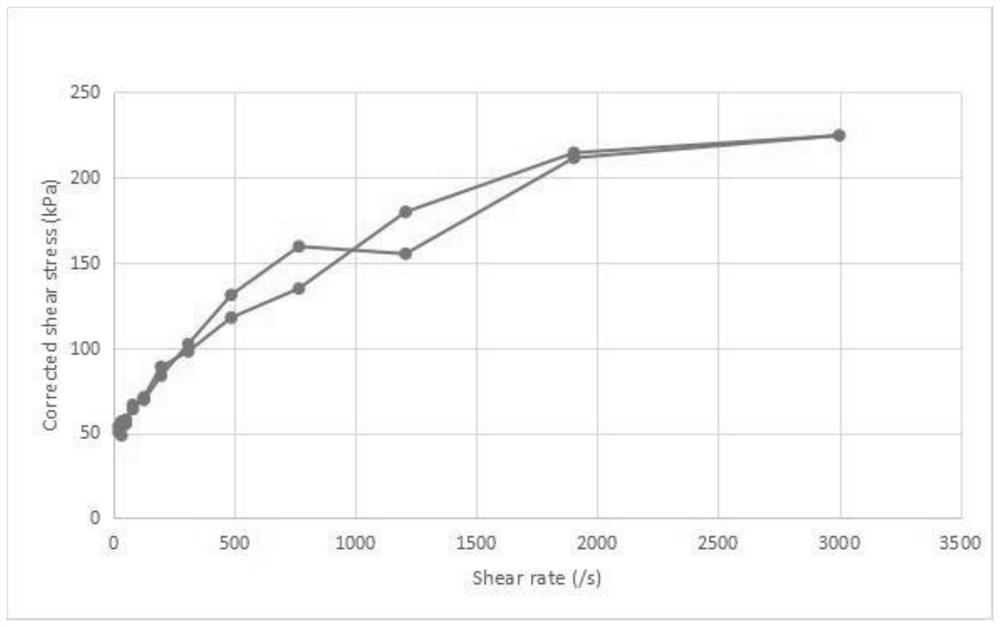

[0027] like figure 1 As shown, this embodiment provides a method for detecting the fluidity of SCR denitration catalyst sludge, including the following steps:

[0028] 1) According to Table 1, each component of the SCR catalyst is kneaded by a small mixer to obtain mud, wherein the model of the small mixer is EIRICH RV 02 / E.

[0029] The small mixer mixes titanium dioxide, additives, active components, water and other substances together, stirs and kneads, and obtains mud of different properties by changing the moisture content and controlling each component. The specific operation is as follows: firstly, the catalyst components shown in Table 1 are added into the small mixer, the blade speed is 1400 rpm, and the dry material is mixed for 5 minutes. Then add water and liquid additives to keep the rotation speed unchanged. When the rotor power is increased to 1.8kw, the remaining titanium dioxide, water and liquid additives are added to the small mixer in turn, and the seconda...

Embodiment 2

[0038] The only difference between this example and Example 1 is that in the catalyst component, the amount of CMC added is 66.3 g.

Embodiment 3

[0040] The only difference between this example and Example 1 is that in the catalyst component, the amount of CMC added is 102 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com