Epoxy resin composition for fiber reinforced composite material and prepreg using same

A technology of epoxy resin and composition, applied in the field of epoxy resin composition, which can solve the problems of low solubility of epoxy resin, decreased heat resistance of cured products, difficulty in stacking prepregs, etc., and achieve excellent storage stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

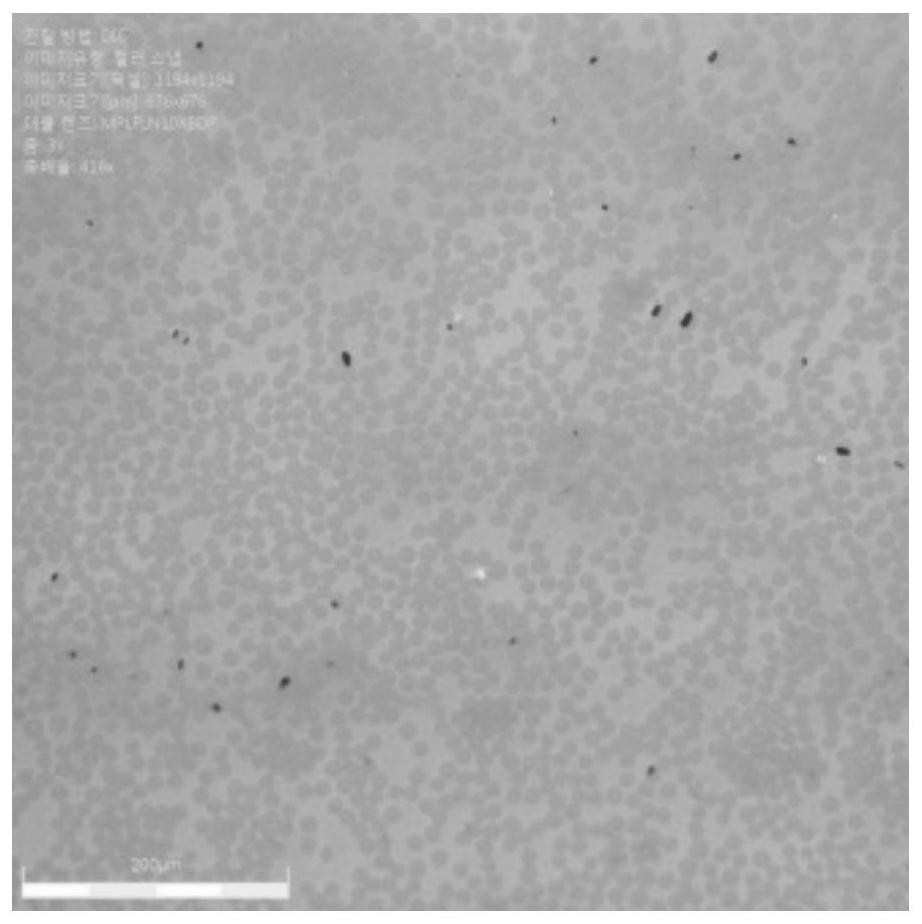

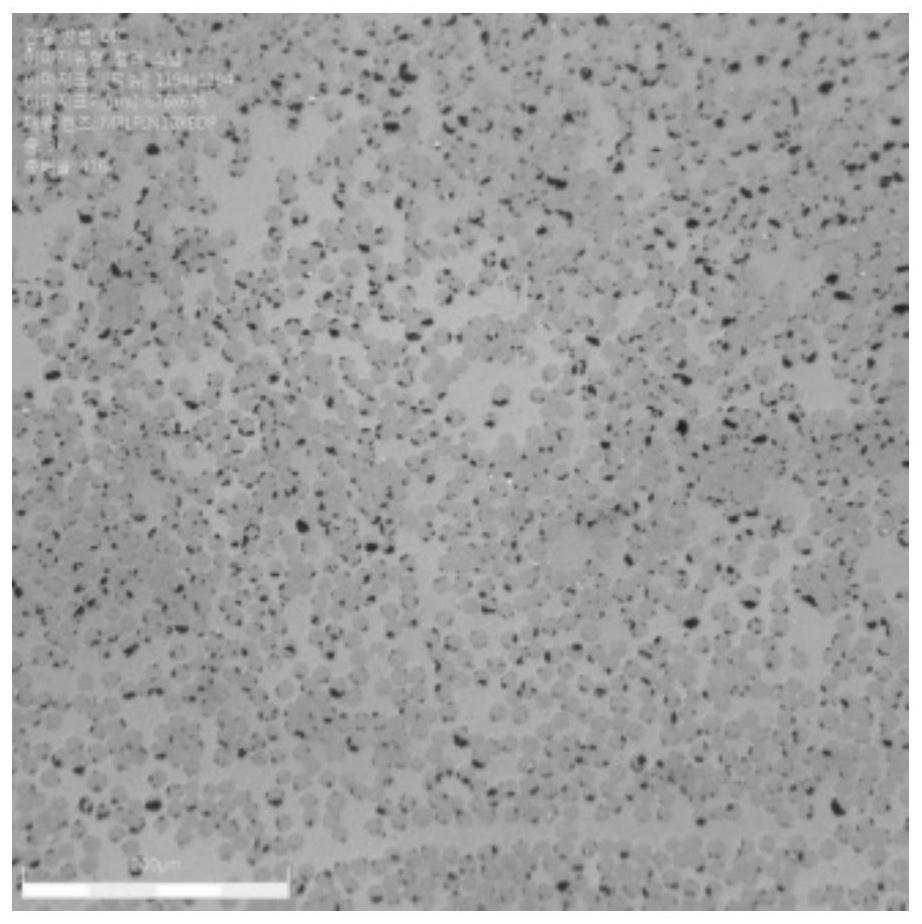

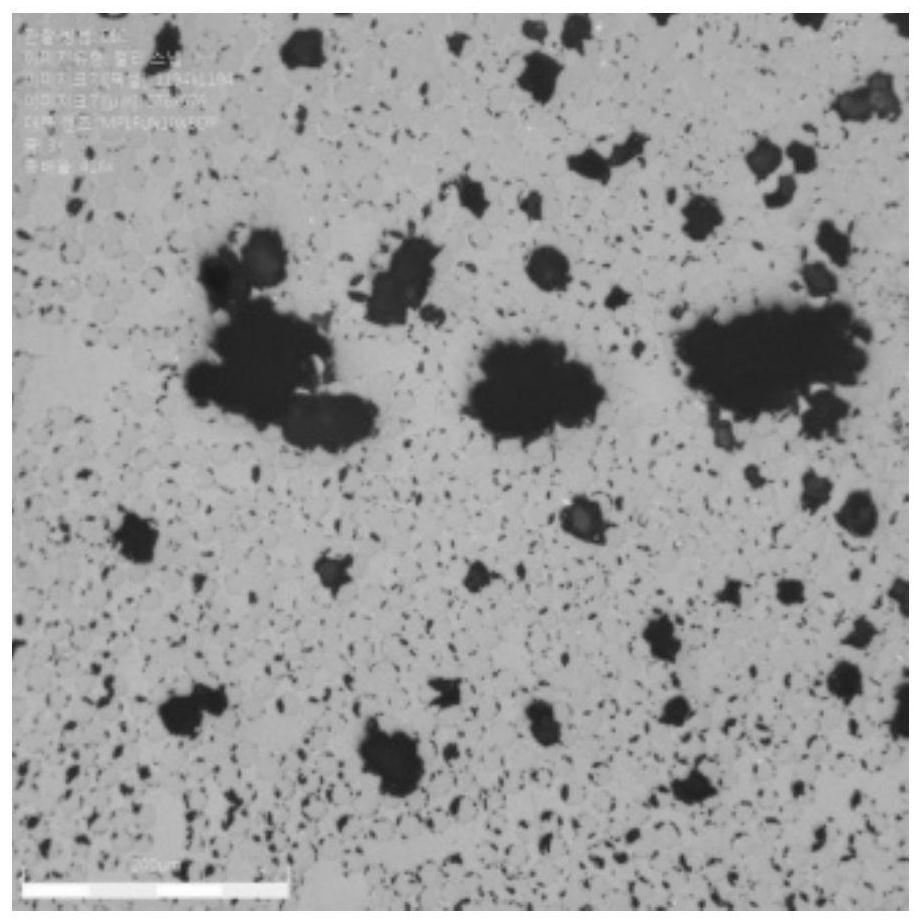

Image

Examples

preparation example Construction

[0045]In particular, in order to mass-produce fiber-reinforced composite materials, the present invention provides an epoxy resin composition and a method for preparing a prepreg using it, wherein the degree of curing is 90% or more or 91% when compression-molded with a mold at 150°C for 3 minutes. % or more, preferably more than 93% or more than 95%, the glass transition temperature (T g ) is 140°C or higher or 141°C or higher, preferably 143°C or higher or 147°C or higher, the fluidity of the resin is controlled, and the molded product has no internal or external defects and is of good quality.

[0046] According to one embodiment of the present invention, there is provided an epoxy resin composition comprising the following components (A), (B), (C) and (D).

[0047] (A) a mixture of bisphenol A type epoxy resin with bifunctionality and glycidylamine type epoxy resin with four functional groups;

[0048] (B) dicyandiamide as epoxy resin curing agent;

[0049] (C) a mixture...

Embodiment 1~4

[0101] Epoxy resin compositions were prepared according to the proportions shown in Table 1 below.

[0102] First, weigh the epoxy resin of component (A) and the thermoplastic resin of component (D) into a glass flask, and stir at 150°C for more than 2 hours to prepare a base resin in which the thermoplastic resin of component (D) is completely dissolved. On the other hand, after weighing the liquid bisphenol A type epoxy resin in the (A) component, that is, EPON 828 12phr and (B), (C) components are mixed, and the mixture is uniformly dispersed by a three-roll machine (3Roll Mill) to Prepare the curing agent slurry. The base resin and curing agent slurry were mixed at a temperature of about 80° C. to prepare an epoxy resin composition.

[0103] It is 107g / m that the weight per square meter of resin is coated with the epoxy resin composition that utilizes comma coater to prepare in this way 2 , so as to prepare a uniform resin film.

[0104] Then, the unidirectional carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com