Industrial control method, device and system based on reinforcement learning and electronic equipment

A kind of industrial equipment and reinforcement learning technology, applied in the computer field, can solve problems such as difficult to solve, long modeling time, high cost, etc., to achieve the effect of ensuring accuracy, short modeling time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

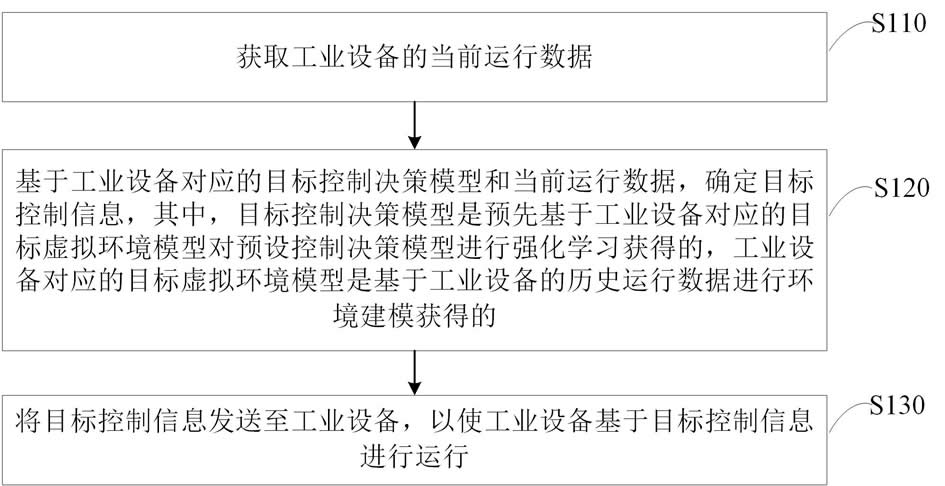

[0030] figure 1 This is a flowchart of an industrial control method based on reinforcement learning provided in Embodiment 1 of the present invention, and this embodiment is applicable to the case of industrial control of industrial equipment. The method may be performed by an industrial control apparatus based on reinforcement learning, the apparatus may be implemented in the form of hardware and / or software, and the apparatus may be configured in an electronic device, such as an industrial controller. like figure 1 As shown, the method specifically includes the following steps:

[0031] S110. Acquire current operation data of the industrial equipment.

[0032] Wherein, the industrial equipment can be any equipment that needs industrial control. The current operation data may refer to the operation data of the industrial equipment at the current moment, which may be used to characterize the current environmental state of the industrial equipment. The current operating dat...

Embodiment 2

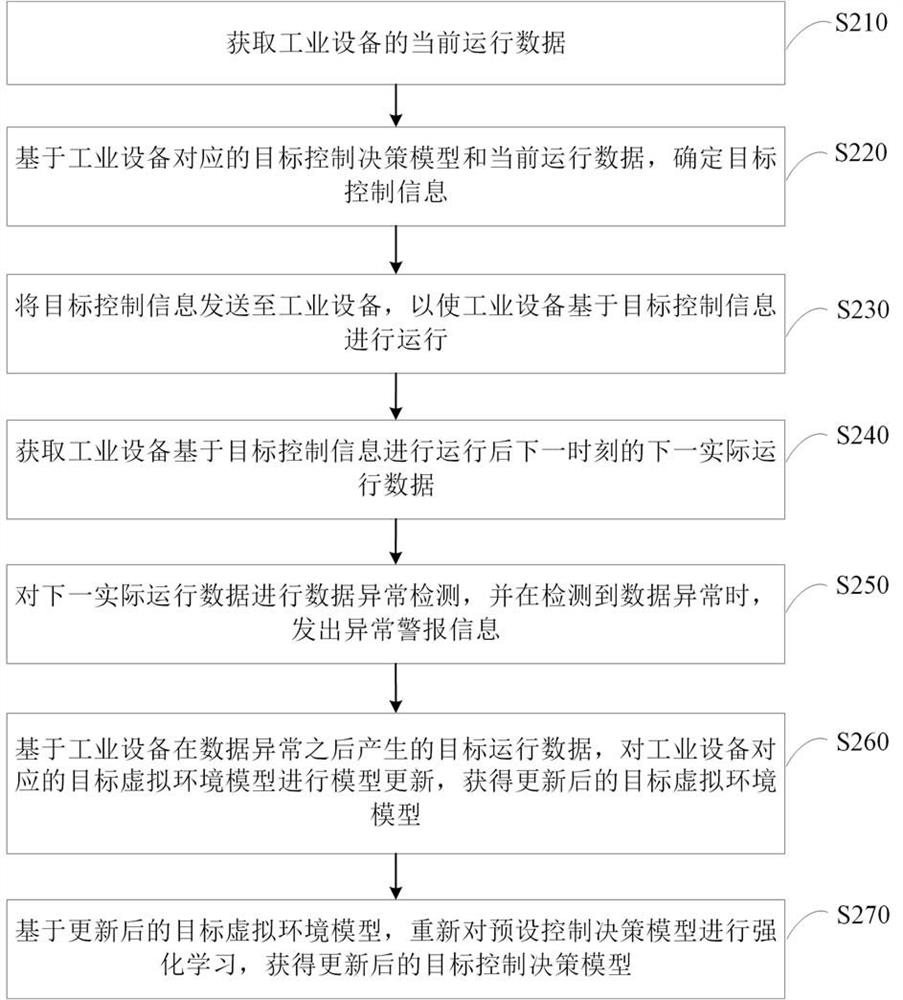

[0051] figure 2 This is a flowchart of an industrial control method based on reinforcement learning provided in the second embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment describes in detail the process of abnormal detection of operating data, and on the basis, The processing process after data anomaly is detected is also described in detail. The explanations of the terms that are the same as or corresponding to the above-mentioned embodiments are not repeated here. see figure 2 , the industrial control method based on reinforcement learning provided by this embodiment specifically includes the following steps:

[0052] S210. Acquire current operation data of the industrial equipment.

[0053] S220. Determine target control information based on the target control decision model corresponding to the industrial equipment and the current operation data.

[0054] S230. Send the target control information to the industrial...

Embodiment 3

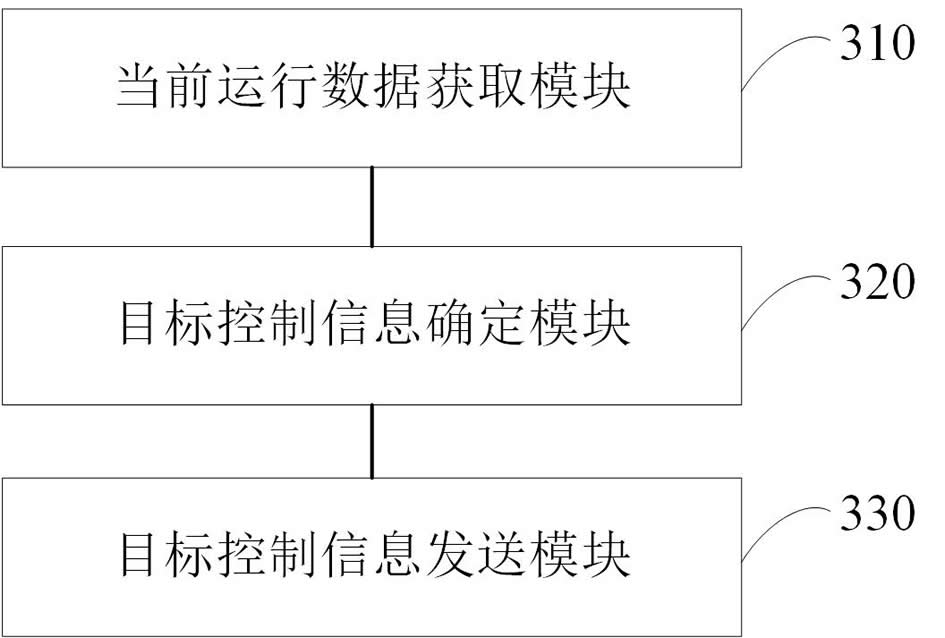

[0069] image 3 This is a schematic structural diagram of an industrial control device based on reinforcement learning provided in Embodiment 3 of the present invention. like image 3 As shown, the device specifically includes: a current operation data acquisition module 310 , a target control information determination module 320 and a target control information sending module 330 .

[0070] Among them, the current operation data acquisition module 310 is used to acquire the current operation data of the industrial equipment; the target control information determination module 320 is used to determine the target control information based on the target control decision model corresponding to the industrial equipment and the current operation data , wherein the target control decision model is obtained by performing reinforcement learning on a preset control decision model based on the target virtual environment model corresponding to the industrial equipment in advance, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com