Color stabilization of biocidal coatings

A technology of biocide and copper particles, applied in biocides, animal repellents, plant growth regulators, etc., can solve problems such as limited commercial utility and decolorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0108] Various concentrations of the copper-containing glass particles described herein were exposed to the pretreatment medium for about 1 hour. The pretreated copper-containing glass particles are then incorporated into a carrier product, which in this example is a latex paint, thereby forming a mixed carrier product. The mixed carrier product was tested "in-can" for color shift and color drift compared to a control (Control A), a latex paint that did not include any copper-containing glass particles. The mixed carrier products were each stored "in the tank" for about 72 hours. The data for the various blended carrier products and the data for Control A are shown in Table 2 as Examples 1-12.

[0109] Unless otherwise specified, the term "color shift" as used herein is used to refer to the change in the color of the carrier upon addition of copper-containing particles, and is the difference between the color of the mixed carrier and copper-containing particles and the absenc...

Embodiment II

[0131] The mixed carrier product was formed according to the example described in Example 1 above. 75 g / gallon of copper-containing glass particles were exposed to the pretreatment medium for various times. The pretreated copper-containing glass particles are then incorporated into a carrier product to form a mixed carrier product. The mixed carrier product was tested "in jar" for color shift and color drift compared to a control (Control B), which was a carrier product that did not include any copper-containing glass particles. The mixed carrier products are each stored "in the tank" for about 120 hours to about 126 hours. The data for the various blended carrier products as well as the data for Control B are shown in Table 4 as Examples 13-23.

[0132] Table 4

[0133]

[0134] Table 5 shows the E of Examples 1-12 c *, L*, C*, and h o The daily percent change values, normalized to the value at 0 hours in the tank.

[0135] table 5

[0136] Example dE...

Embodiment III

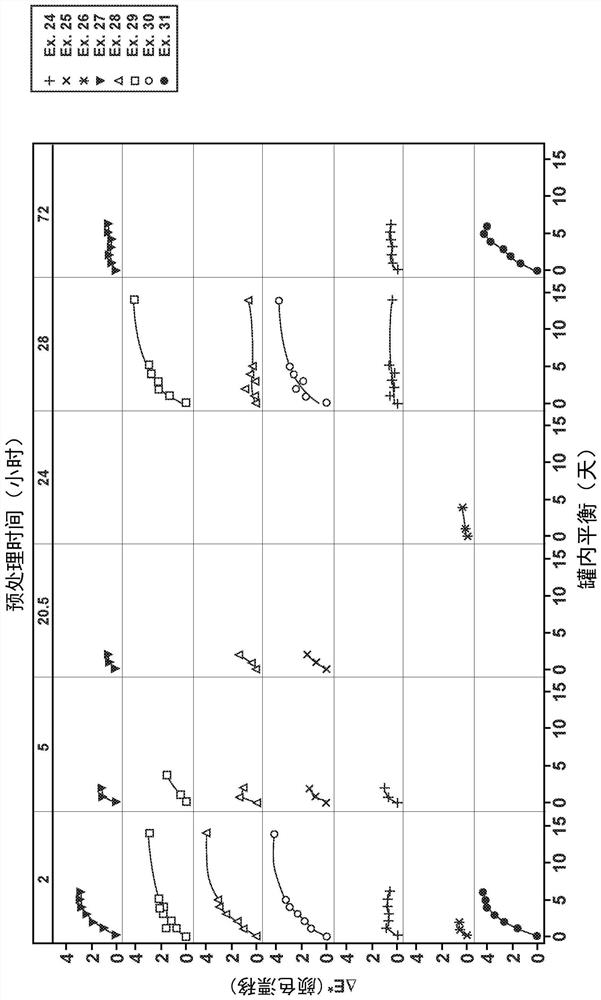

[0139] figure 1 is a graph illustrating the color shift of the paint as the paint ages in the can for paints treated with copper-containing particles treated with different pretreatment solutions (Ex. 24-31). The copper-containing particles were pretreated with the pretreatment solution for various times (2, 5, 20.5, 24, 48 and 72 hours) as indicated above the graph ("Pretreatment Time") prior to combining with the paint.

[0140] Prepared by weighing approximately 1.5 g of copper-containing glass particles into a jar, then adding 2 mL of pretreatment solution to the jar and stirring continuously for the indicated pretreatment times (2, 5, 20.5, 24, 48, and 72 hours) Ex.24-31. At the end of the pretreatment time, an amount of commercially available latex paint was added to the jar to give a dosage of 75 g of copper-containing particles per gallon of paint (75 g / gal) and the mixture was mixed for 10 minutes using an overhead mixer. The color of each treated paint Ex. 24-31 wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com