Preparation method of transparent coated chewing gum containing colored saccharide compound particles

A chewing gum and compound technology, which is applied in the field of preparation of transparent coated chewing gum containing colored sugar compound particles, can solve the problems of insufficient crispness and high cost of consumer groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

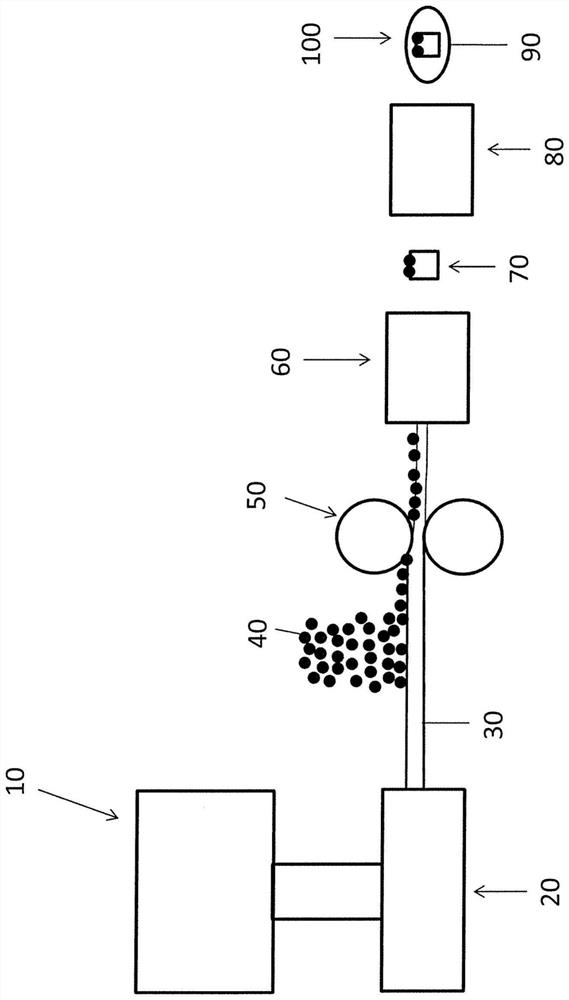

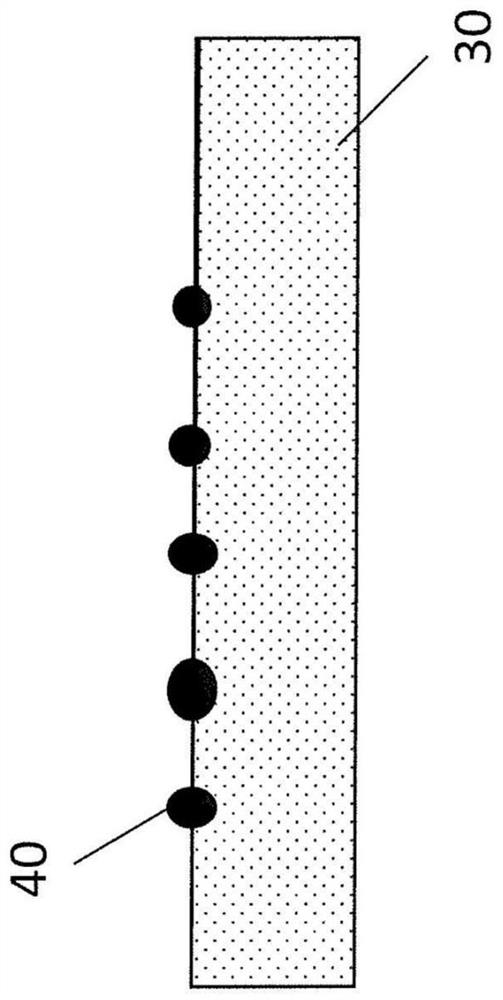

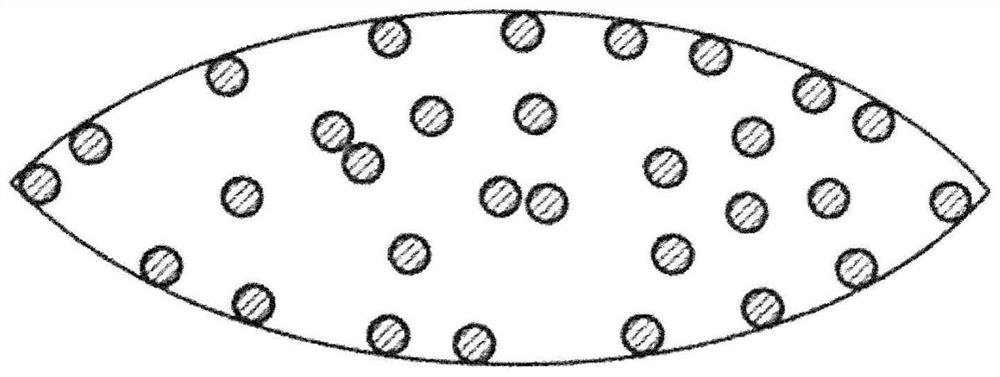

[0136] The following chewing gum core components are provided to prepare clear coated chewing gum comprising a heterogeneous chewing gum core and a clear sugar coating surrounding the core.

[0137] Gum core components:

[0138] Chewing gum base "TFL3" (Euobase) 16.00wt.% Gum base "TULI Mod2" (Euobase) 16.00wt.% Sorbitol (P60, Roquette, average particle size 230μm) 29.20wt.% Isomalt ST PF (Beneo) 25.00wt.% Maltitol Syrup (Lycasin 80 / 55) (Roquette) 10.60wt.% mint spice 1.50wt.% Menthol Fragrance 1.50wt.% Acesulfame-K 0.10wt.% aspartame 0.10wt.%

[0139] In addition, isomalt ST-PNC particles are also provided. Isomalt ST-PNC particles are isomalt ST particles with a particle size of 0.8 mm to 1.25 mm. Isomalt ST-PNC granules were dyed using a tinting solution in a continuously agitated coating pan. To obtain green granules, 12.5 kg of isomalt ST-PNC granules were stained with 600 g of 0.05% "Brilliant Gree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com