Plastic syringe needle separating device for hematology department

A technology for separation devices and syringes, which can be used in the direction of needles, plastic recycling, and instruments introduced into the body, and can solve problems such as inconvenient classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

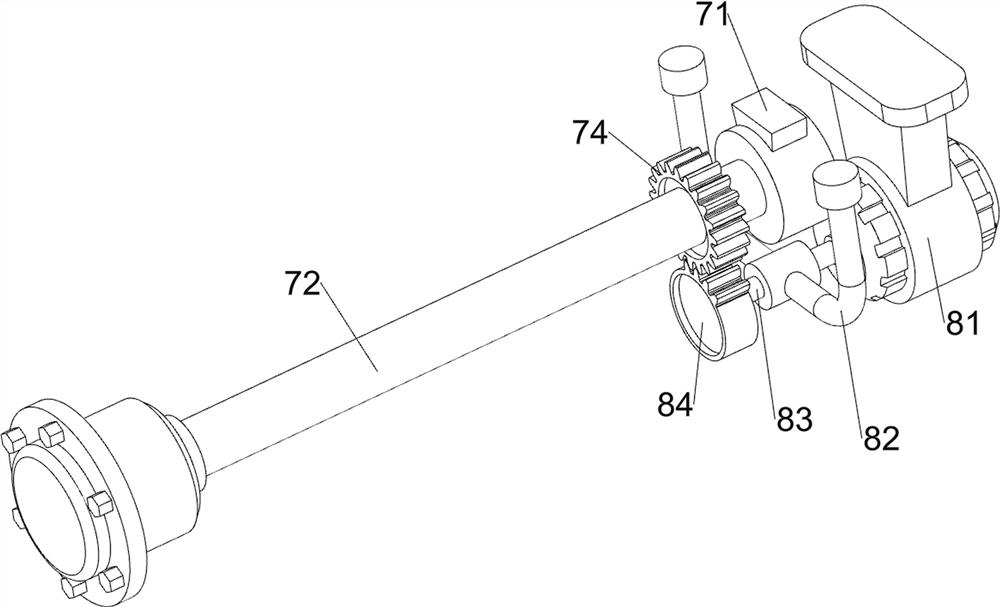

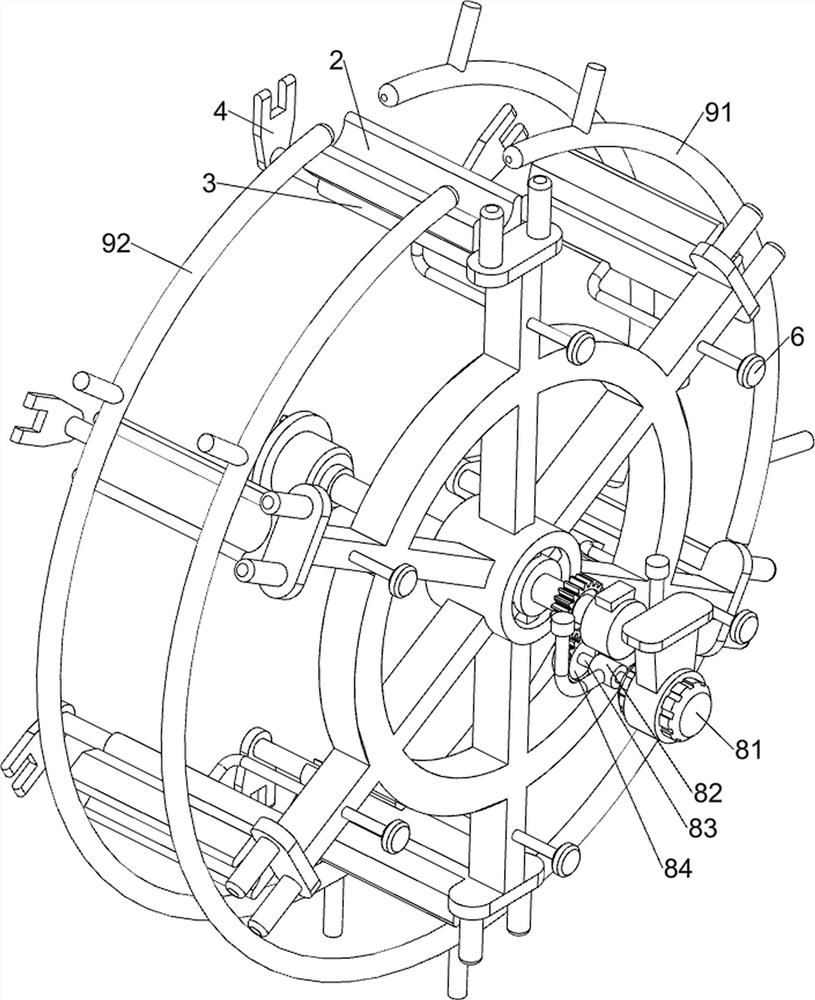

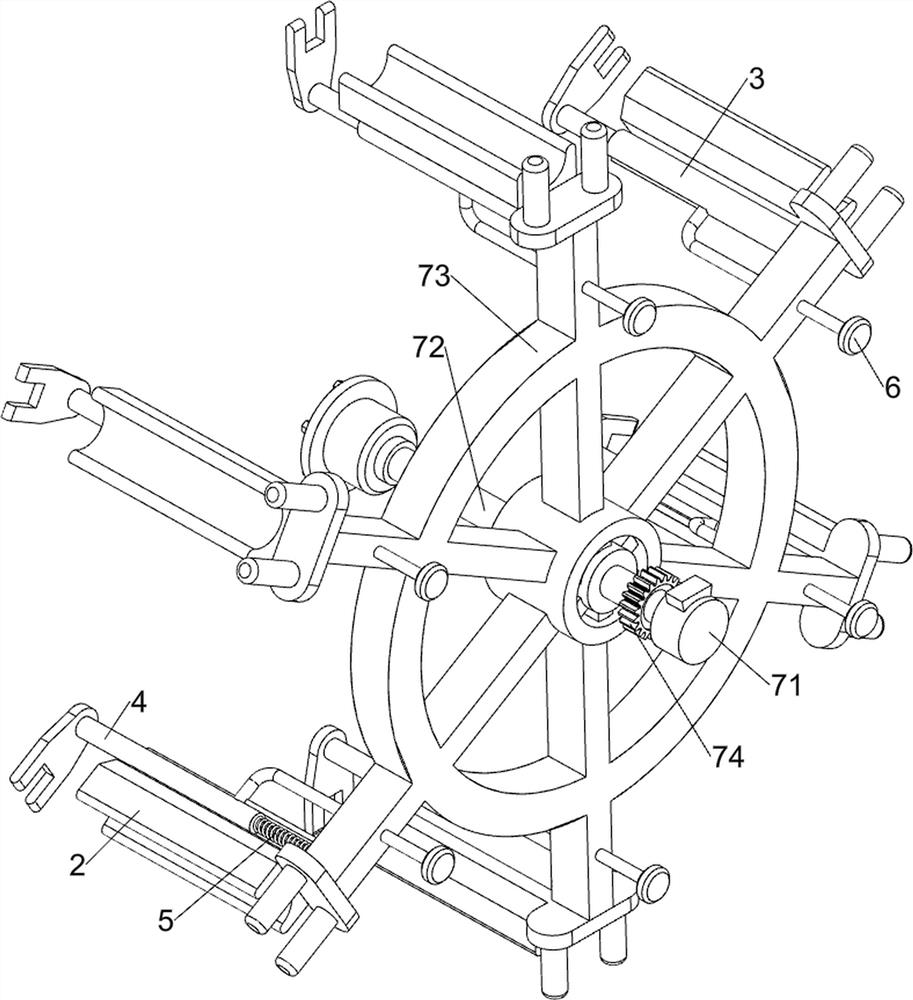

[0039] A plastic syringe needle separation device for use in hematology, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, it includes a casing 1, a first bracket 1001, a second bracket 1002, a placing seat 2, a sliding cylinder 3, a push rod 4, a return spring 5, a contact rod 6, a rotating mechanism 7, a driving mechanism 8, a limiter For the mechanism 9 and the separation mechanism 10, the bottom of the casing 1 is provided with a first bracket 1001 symmetrically, the front side of the bottom of the casing 1 is provided with a second bracket 1002, the inner side of the casing 1 is provided with a rotating mechanism 7, and the components of the rotating mechanism 7 surround There are six placing seats 2 evenly, the inner side of the placing seats 2 are all provided with sliding cylinders 3, and the sliding cylinders 3 are all slidably provided...

Embodiment 2

[0046] On the basis of Example 1, as Figure 14 , Figure 15 , Figure 16 , Figure 17 and Figure 18 As shown, it also includes a blanking assembly 11, and the blanking assembly 11 includes a first guide rod 111, a second guide rod 112, a sliding frame 113, a second spring 114, a guide shaft 115, an ejector rod 116, and a third spring 117 and the wedge-shaped block 118, a first guide rod 111 is provided on the left rear part of the housing 1, a second guide rod 112 is provided on the left rear part of the housing 1, and the second guide rod 112 is located at the position of the first guide rod 111. Below, a sliding frame 113 is slidably connected between the first guide rod 111 and the second guide rod 112 , and a second spring 114 is connected between the sliding frame 113 and the first guide rod 111 and the second guide rod 112 . The springs 114 are respectively sleeved on the first guide rod 111 and the second guide rod 112 , and guide shafts 115 are provided on the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com