Crucible lifting appliance capable of automatically unhooking and crucible lifting method

A technology of automatic decoupling and hoisting method, which is applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of difficulty in automatic operation, inability to get rid of manual picking, and low manual handling efficiency, and achieves overall simplicity and practicality. Simple structure , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further illustrated by the following examples.

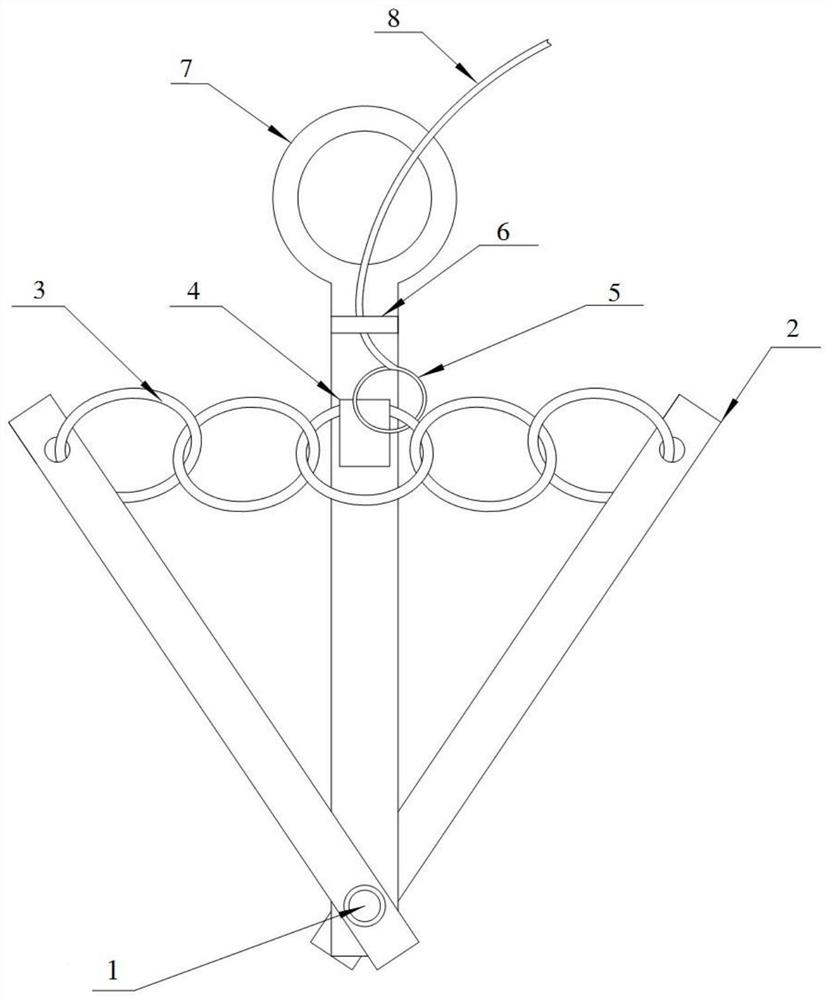

[0029] A crucible spreader that can be automatically decoupled, including a pull rod, characterized in that the upper end of the pull rod is provided with a lifting ring 7, the lifting ring 7 is connected with the hook of the traveling vehicle, the pull rod is located under the lifting ring 7 and is provided with a side hook 4, and the lower end of the pull rod is provided with a side hook 4. Symmetrically arranged support arms 2 are hinged to form a scissors fork, and the support arms 2 on both sides are connected by a connecting piece 3. The connecting piece 3 is a flexible structure, and a limiting ring is provided on the connecting piece 3 and the limiting ring is connected There is a decoupling ring 5, a decoupling rope 8 is connected to the decoupling ring 5, and the upper end of the decoupling rope 8 is limited by the limiter 6 on the pull rod. The limiter 6 is a limit ring or a limit hole s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com