Graphite block, graphite member and method for inhibiting expansion of negative electrode graphitization box-type furnace

A graphite block and box-type furnace technology, applied in the field of carbon materials, can solve the problems of box plate deformation, inability to avoid the problem of powder expansion in the box, and difficult operation, so as to achieve a basically constant axial pressure range and reduce severe oxidation spraying. Furnace risk, the effect of protecting the structure of the furnace head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

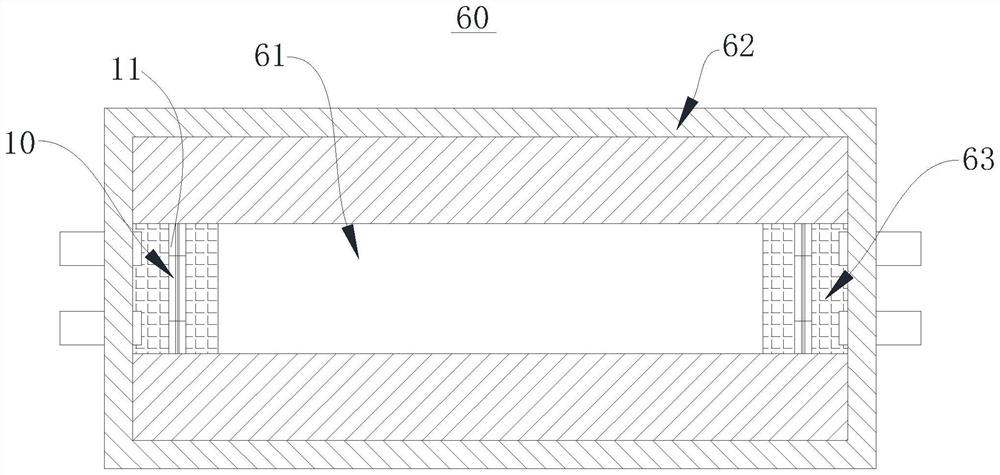

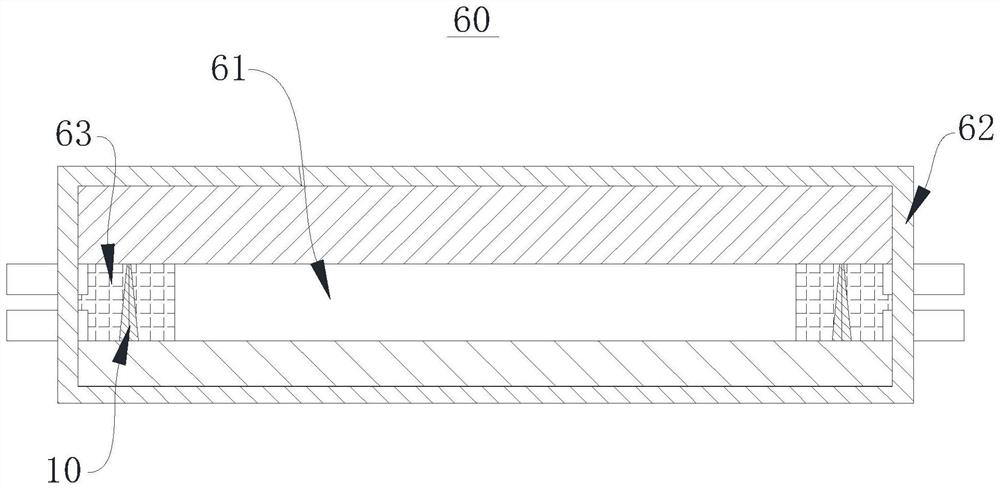

[0047] Please refer to figure 1 and figure 2 , This embodiment provides a graphite block 11, the graphite block 11 is in the shape of a bar. The length direction perpendicular to the graphite block 11 is set as the first preset direction, and the cross section of the graphite block 11 along the first preset direction is an isosceles trapezoid. In this embodiment, further, the acute angle of the isosceles trapezoid is less than or equal to 85°, so as to ensure that the slope of the graphite block 11 has a sufficient slope.

[0048] The present embodiment provides a graphite member 10, and the graphite member 10 is composed of a set of graphite groups. The graphite group consists of at least one graphite block 11 continuously arranged along the length direction, and the cross-sections of the graphite blocks 11 in the same group along the first preset direction overlap.

[0049] This embodiment also provides a method for suppressing the expansion of the negative electrode gra...

Embodiment 2

[0056] For the parts not mentioned in this embodiment, reference may be made to Embodiment 1.

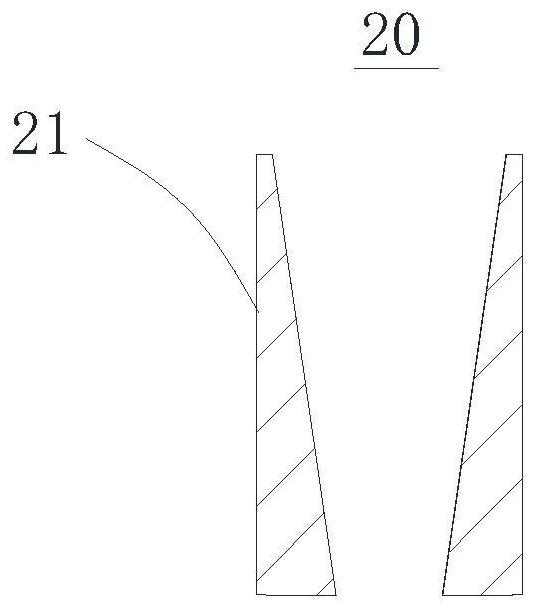

[0057] Please refer to image 3 and Figure 4 , in this embodiment, the cross section of the graphite block 21 along the first preset direction is a right-angled trapezoid. In this embodiment, further, the acute angle of the right-angled trapezoid is ≤85°.

[0058] This embodiment provides a graphite member 20, and the graphite member 20 is composed of two groups of graphite groups. The graphite group consists of a plurality of graphite blocks 21 that are continuously arranged along the length direction, and the cross-sections of the graphite blocks 21 located in the same group along the first preset direction overlap. The length directions of the adjacent two groups of graphite groups are arranged in parallel, and the arrangement direction of the adjacent two groups of graphite groups is set as a second preset direction, and the second preset direction is perpendicular to the le...

Embodiment 3

[0062] For the parts not mentioned in this embodiment, reference may be made to Embodiment 1.

[0063] Please refer to Figure 5 and Image 6 , In this embodiment, the cross section of the graphite block 31 along the first preset direction is a right-angled trapezoid. In this embodiment, further, the acute angle of the right-angled trapezoid is ≤85°.

[0064] This embodiment provides a graphite member 30, and the graphite member 30 is composed of two groups of graphite groups. The graphite group consists of a plurality of graphite blocks 31 arranged continuously along the length direction, and the cross-sections of the graphite blocks 31 in the same group along the first preset direction overlap. The length directions of the adjacent two groups of graphite groups are arranged in parallel, and the arrangement direction of the adjacent two groups of graphite groups is set as a second preset direction, and the second preset direction is perpendicular to the length direction an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com