Multilayer continuous cavitation impinging stream reactor

A technology of impinging flow reactors and reaction disks, applied in the field of multi-layer continuous cavitation impinging flow reactors, can solve the problems of low sewage treatment efficiency, accelerating the reaction speed of chemicals and compounds in sewage, etc., to promote energy exchange and increase molecular Kinetic energy, the effect of increasing reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make those skilled in the art better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely below with reference to the accompanying drawings in the embodiments of the present invention.

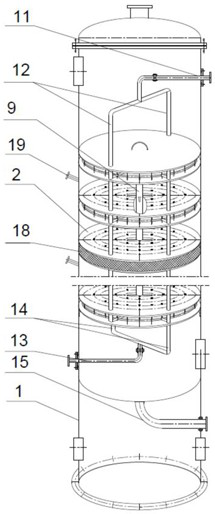

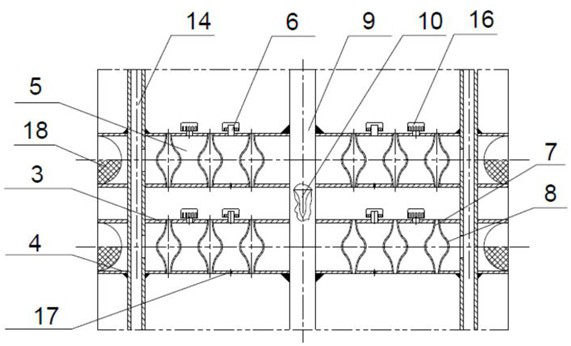

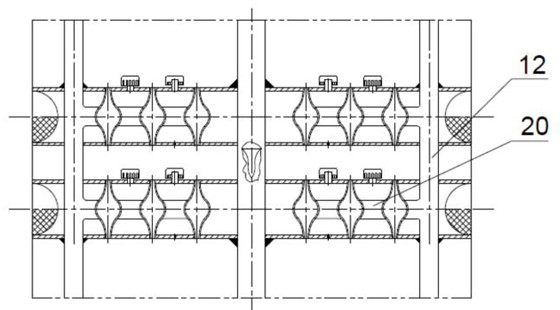

[0021] as attached figure 1 As shown, the present embodiment provides a multi-layer continuous cavitation impingement flow reactor, including a reaction chamber 1, a liquid conduit and an air conduit are arranged in the reaction chamber 1, and a plurality of upper and lower sequentially distributed reactors are arranged in the reaction chamber 1. Reaction plate 2, the reaction plate 2 is provided with an upper cover plate 3 and a lower cover plate 4, an air guide chamber 5 is reserved between the upper cover plate 3 and the lower cover plate 4, and the air guide pipe passes through each reaction plate 2 , and the air guide pipe is communicated with the air gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com