Industrial wastewater treatment equipment with good safety

A technology of industrial wastewater and treatment equipment, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of cleaning personnel injury, unresolved, ignoring the safety of industrial wastewater, etc. , to achieve rapid replacement and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

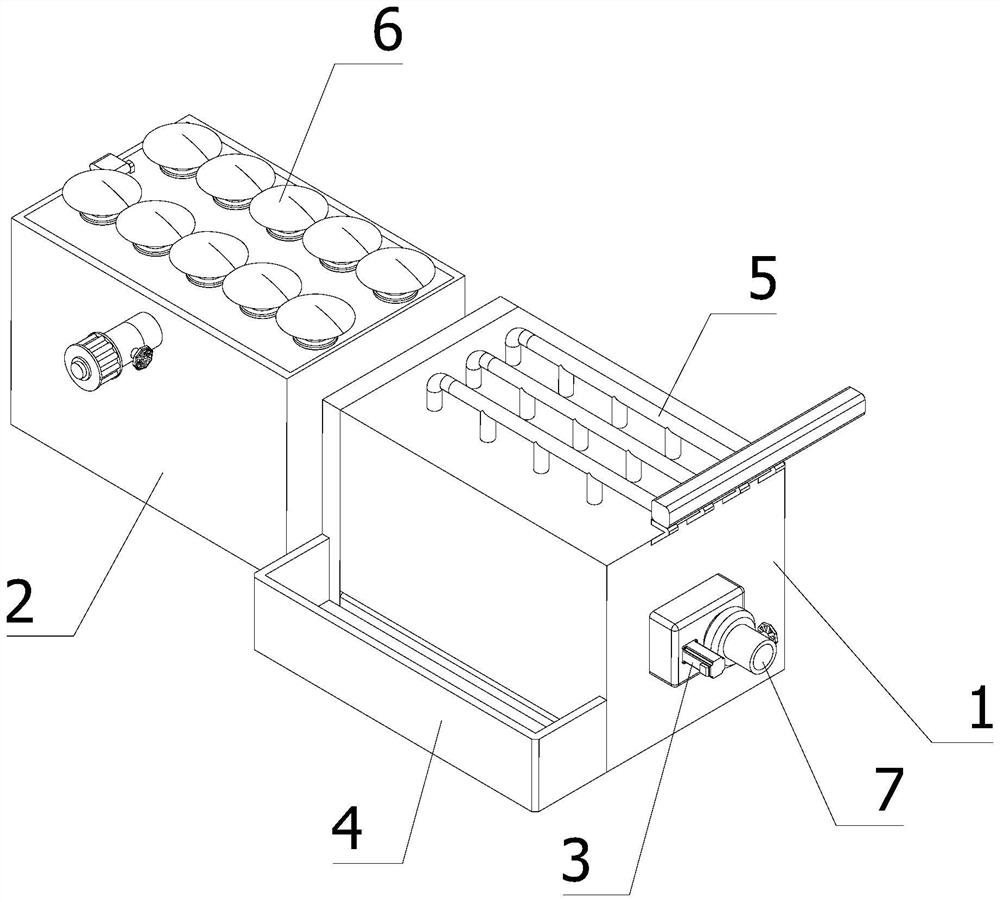

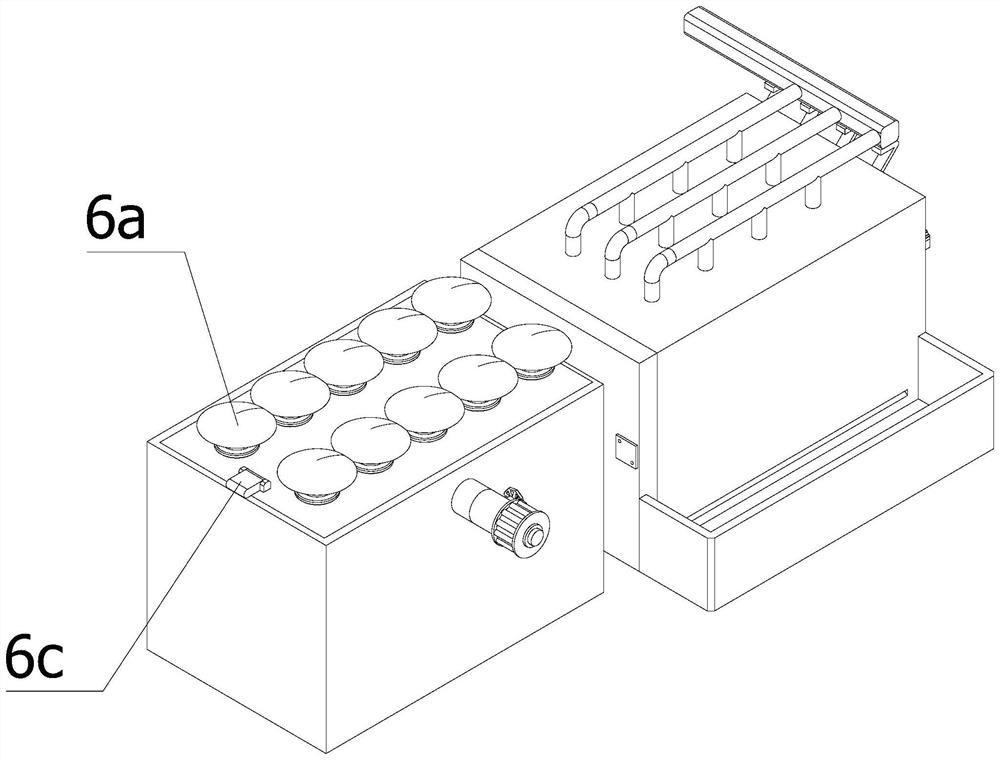

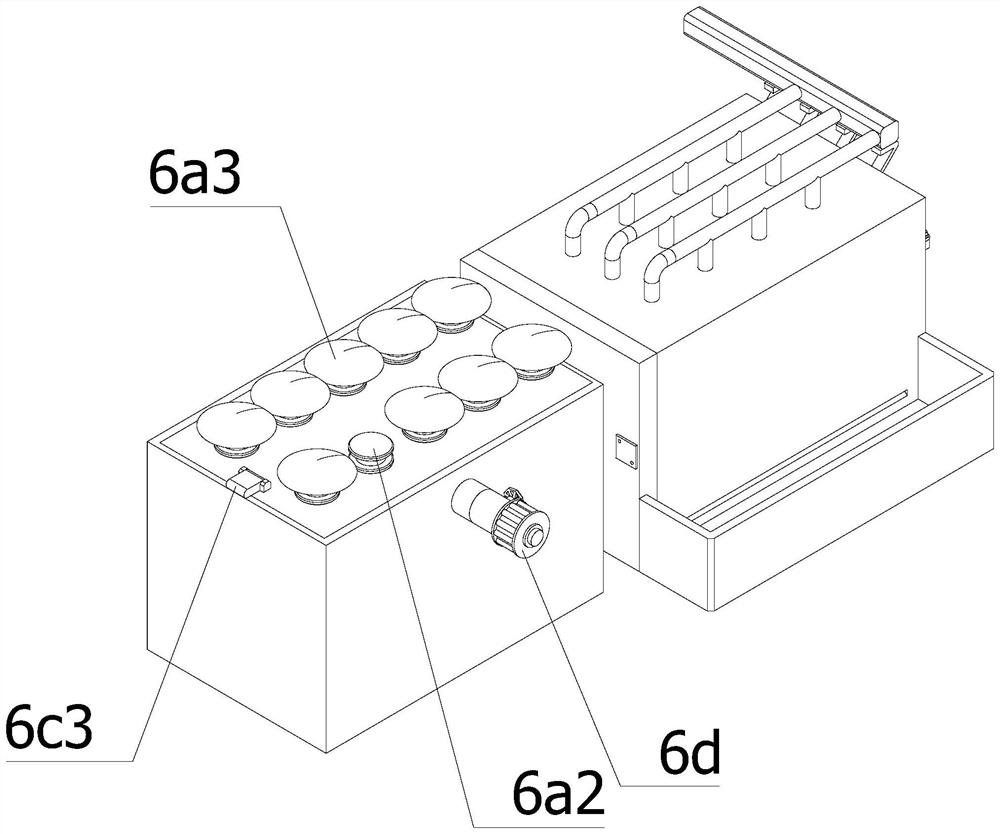

[0046] like Figure 1-15 As shown, the present invention provides:

[0047] An industrial wastewater treatment equipment with good safety, comprising a first box 1, a second box 2, a scraping mechanism 3, a heavy metal removal mechanism 5, a microorganism treatment mechanism 6 and a first on-off valve 7; and a recovery mechanism 4; The scraping mechanism 3 includes a gear ring 3a, a transmission assembly 3b, a drive assembly 3c, a first hinged seat 3d, a baffle 3e, a scraper 3f, a first stopper 3g, a central shaft 3h and a second stopper 3j The inside of the first box body 1 is provided with a rotating cavity, and the central shaft 3h is rotatably arranged on the side wall of the first box body 1 along the axis of the rotating cavity; the gear ring 3a is rotatable along the axis of the central shaft 3h respectively It is arranged on the side walls of both ends of the rotating cavity; a transmission assembly 3b is arranged between the gear ring 3a and the central shaft 3h; the...

Embodiment 2

[0074] further, as Image 6 and Figure 10 shown:

[0075] The recovery mechanism 4 includes a recovery box 4b and a recovery slot 4a; the recovery slot 4a is opened between the first blocking member 3g and the second blocking member 3j; on the wall.

[0076] Based on the above embodiments, the technical problem to be solved by the present invention is how to collect the heavy metal crystals scraped by the scraping mechanism 3 . For this reason, according to the present invention, after the scraper 3f is in contact with the second stopper 3j, the second stopper 3j will scrape off the heavy metal crystals on the scraper 3f, and then the heavy metal crystals will fall on the first stopper 3g up, slide out from the recovery tank 4a, and finally fall into the recovery box 4b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com